Did you know that you can view MUCH more of our work on Facebook ?

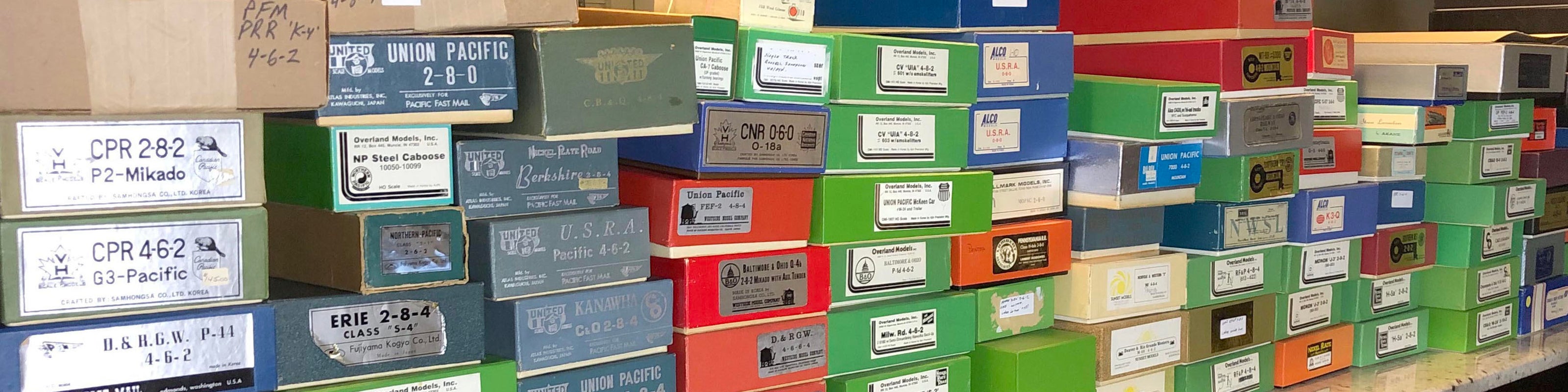

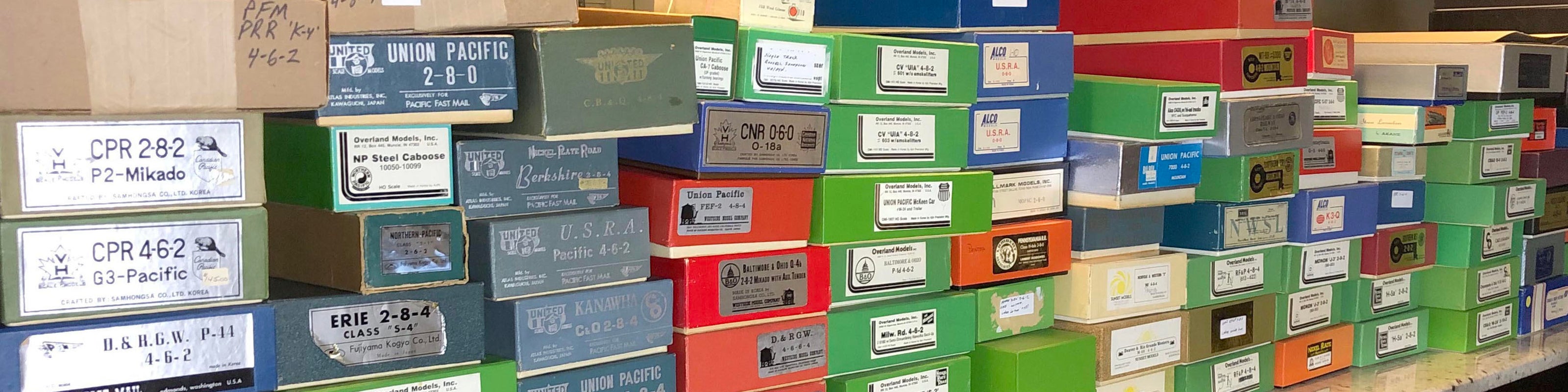

With more than 2,500 images available, it's truly the finest source of online information available to current and potential clients, brass collectors and operators, and hobby shop repair departments wanting to learn more about how we repair, restore, paint and weather brass model trains. Below, we've included just 18 examples of the kinds of things we write about in depth on our Facebook page. The complete stories and all of the high-resolution images that go with each of them are only available on our Facebook page. It's all FREE to you if you have a Facebook account and FOLLOW THIS LINK: https://www.facebook.com/JeffLemkeTrains/

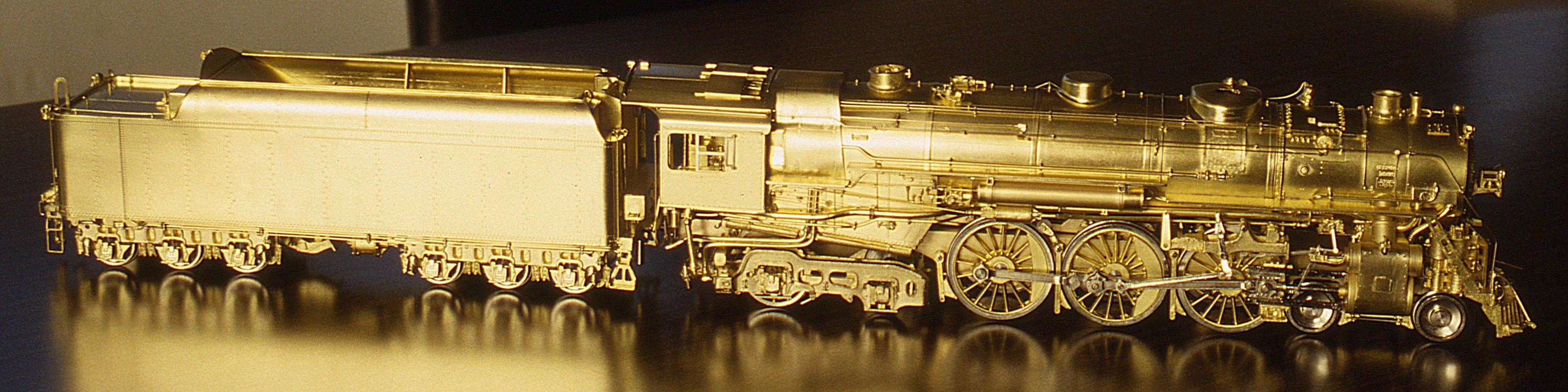

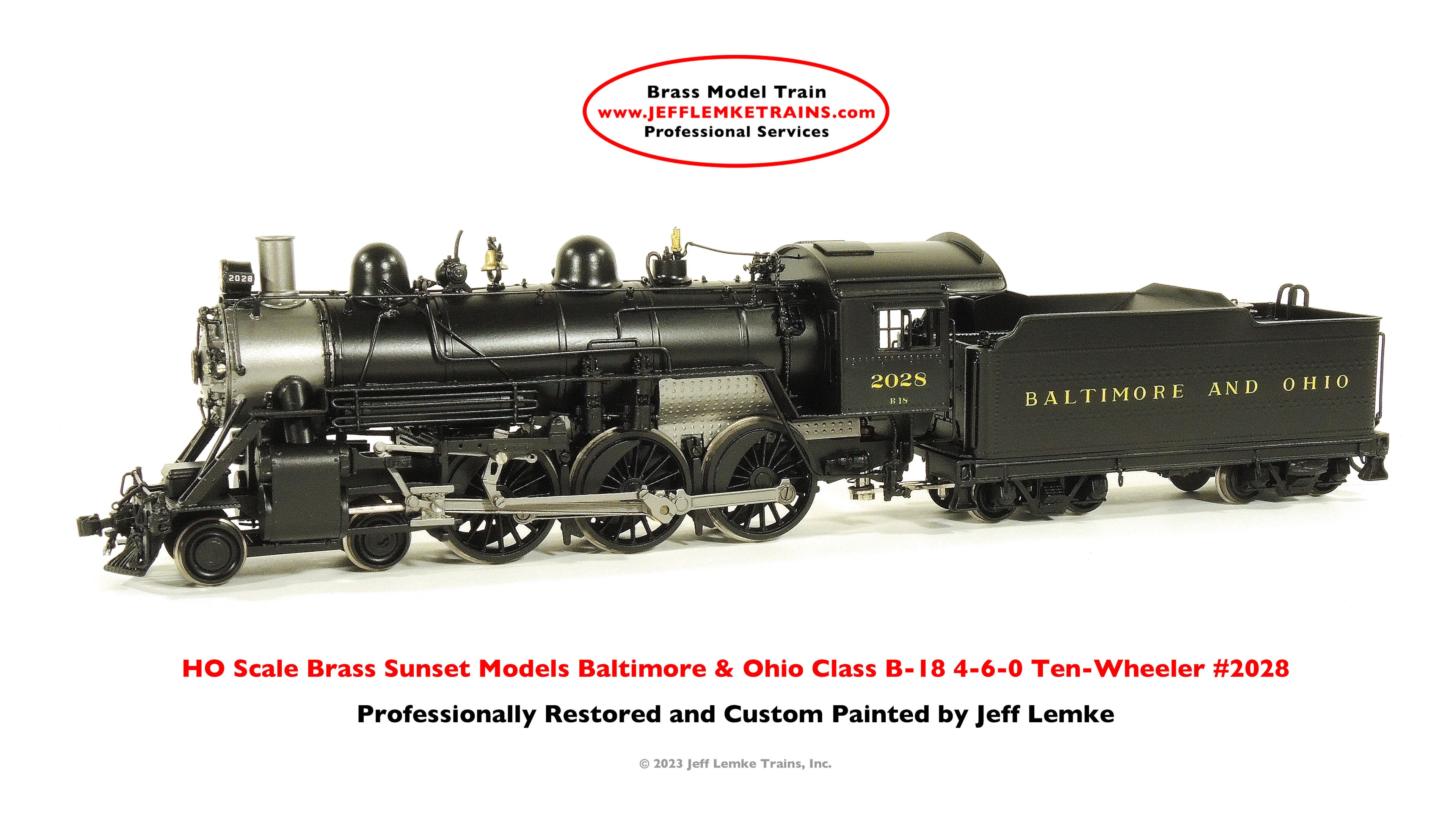

Paint Work and Brass Restorations

-

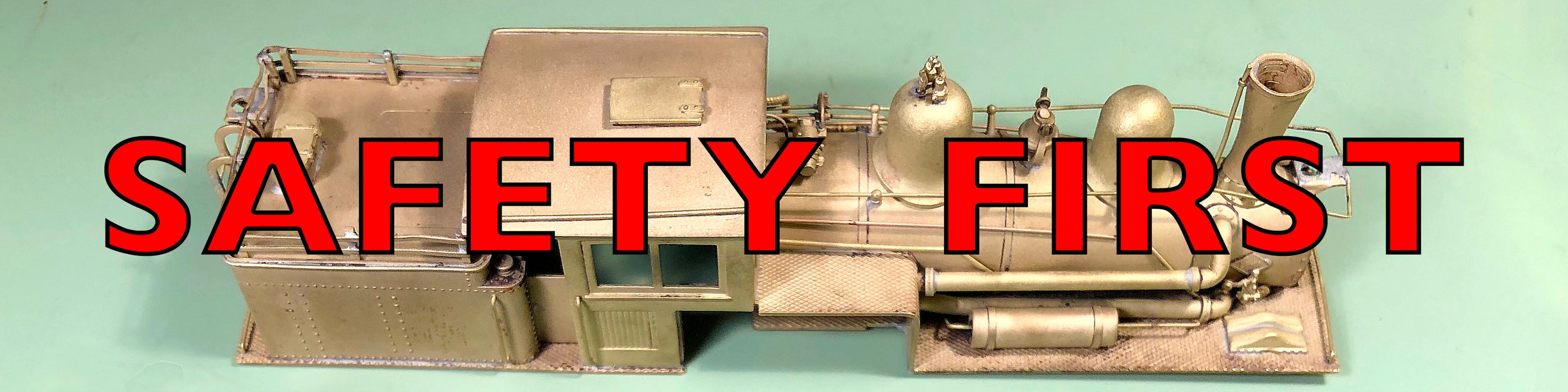

See Larger Image

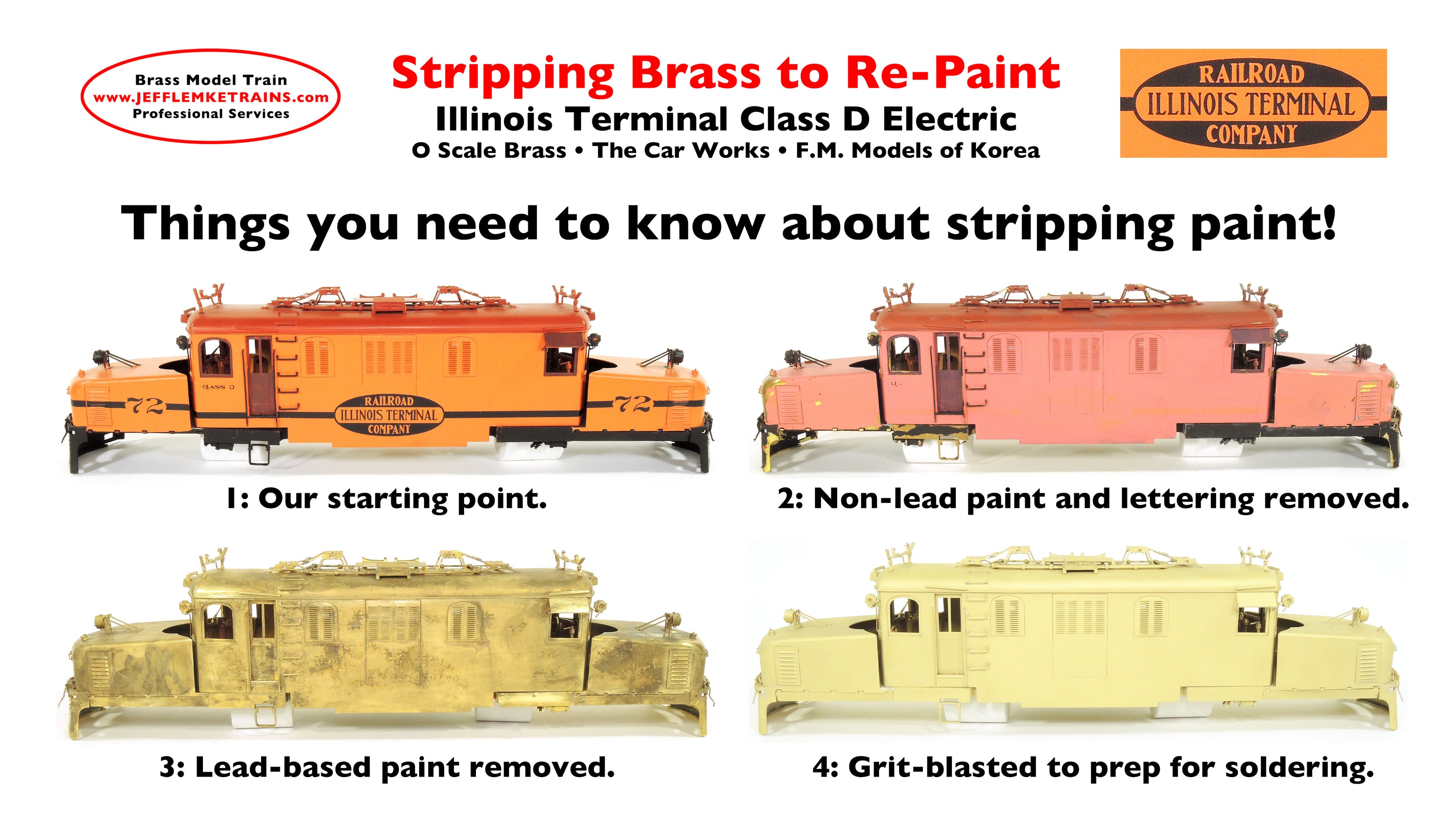

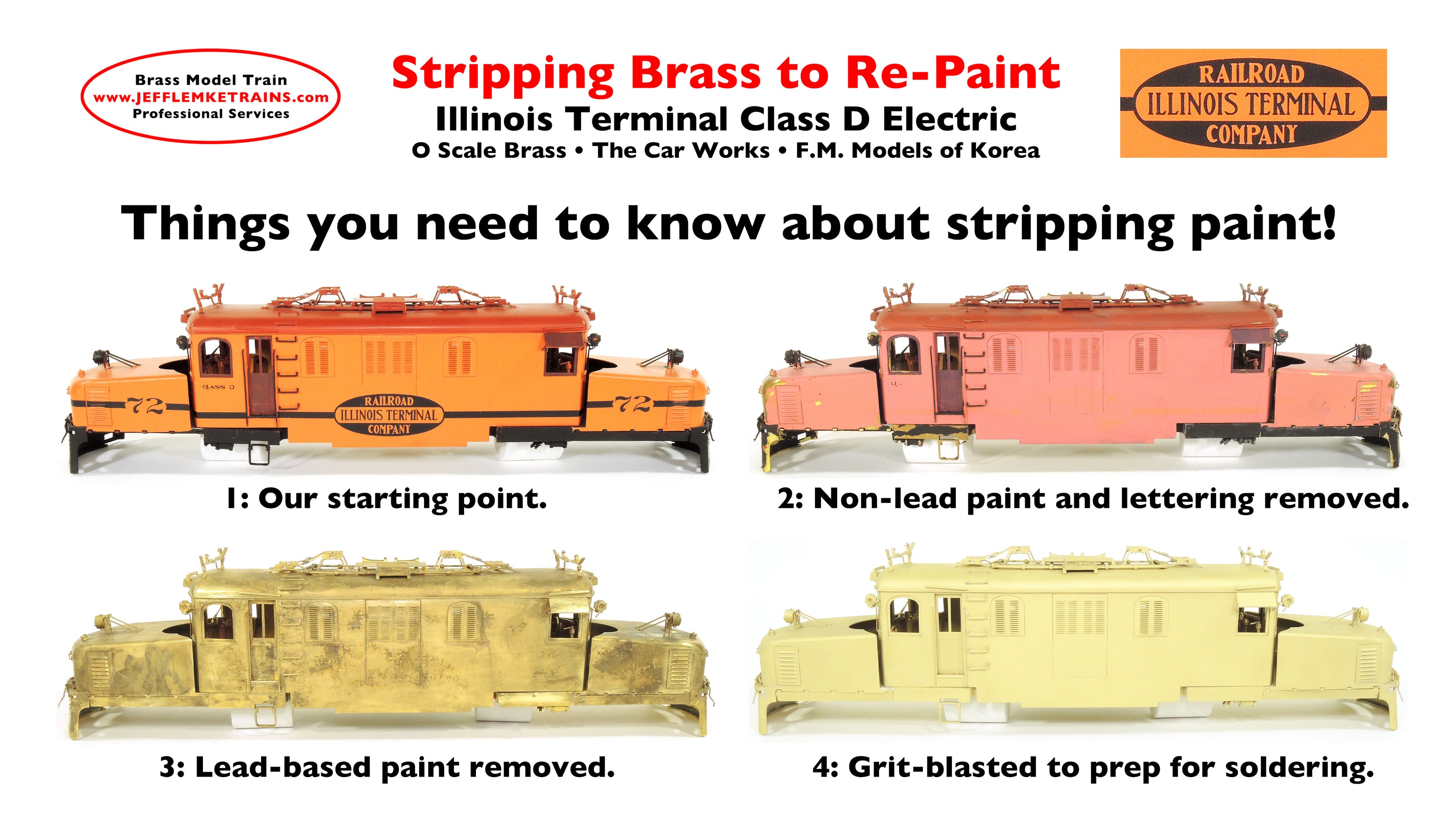

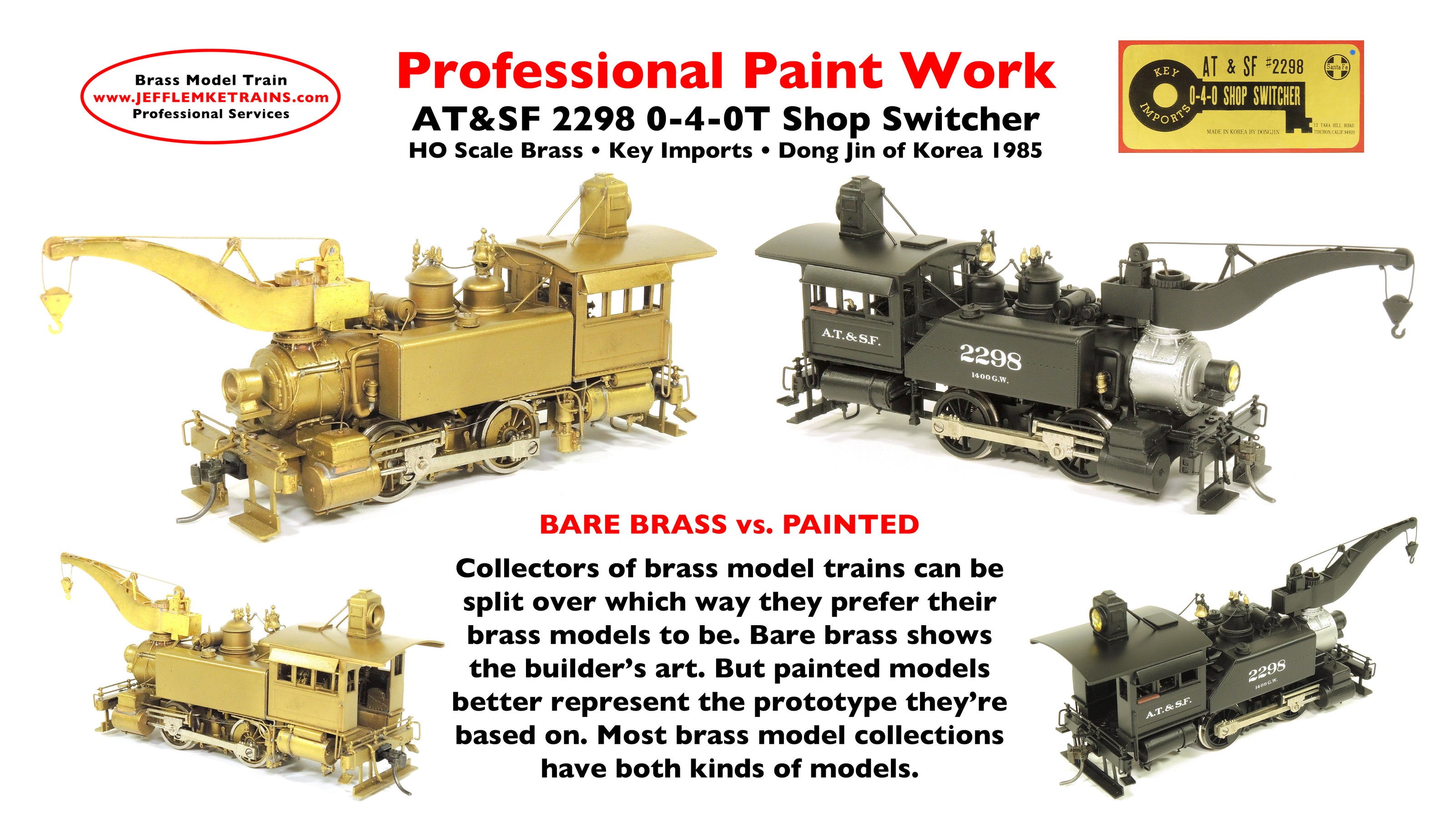

See Larger ImageOur Facebook pages discusses why many Korean-made brass models can have factory paint that's difficult to remove.

-

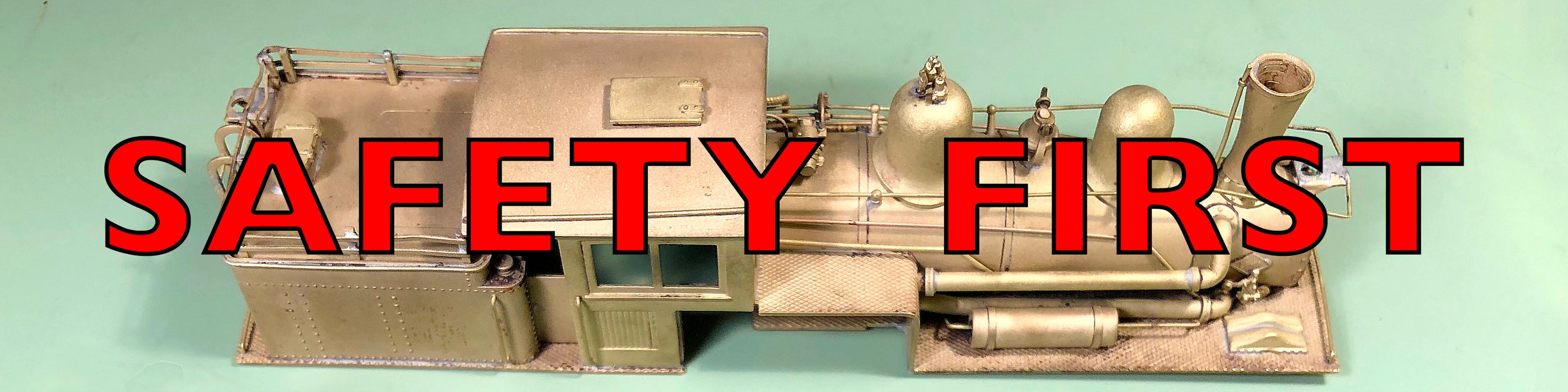

See Larger Image

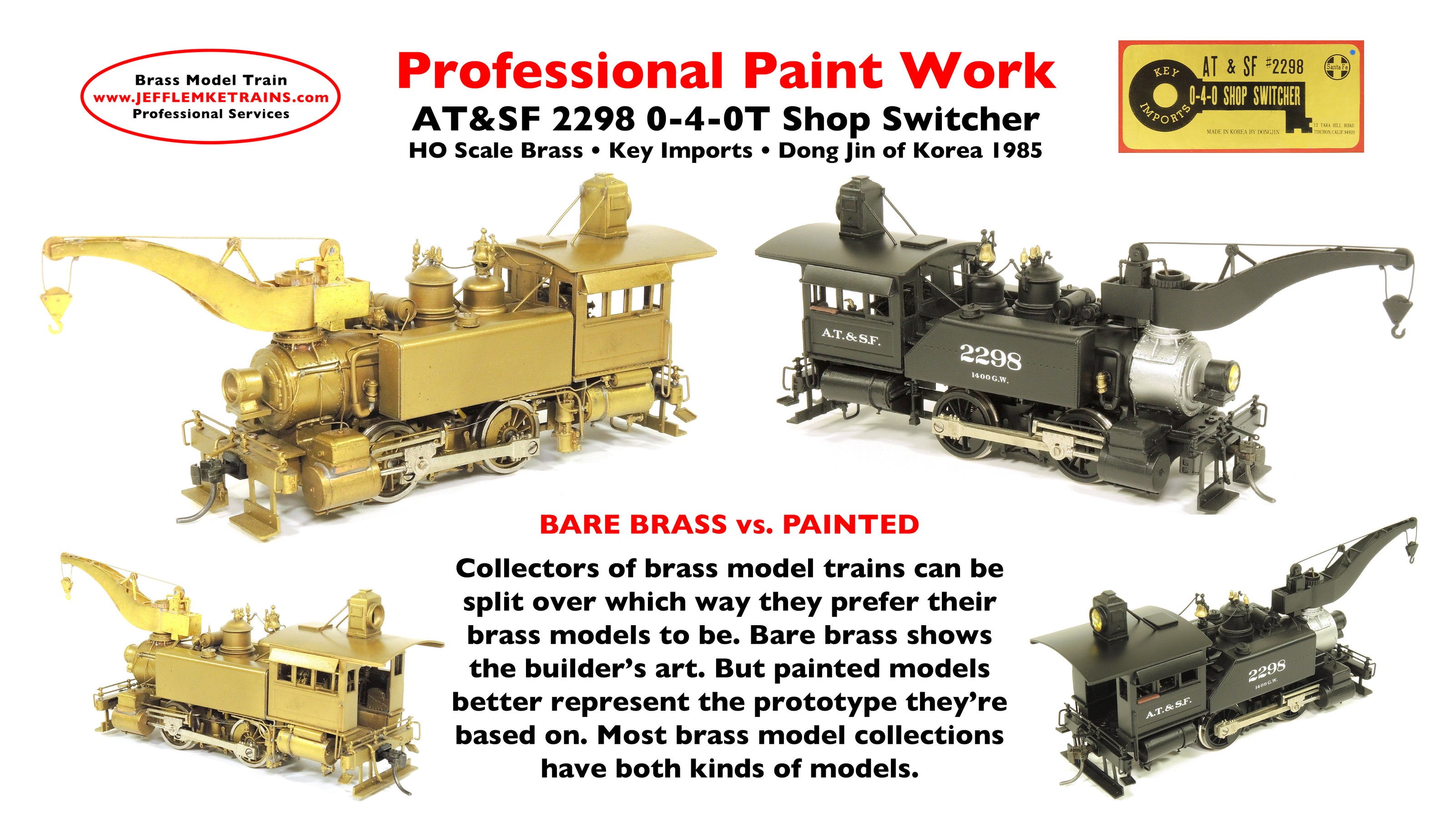

See Larger ImageIt also provides professional advice on how to create the finest paint work on brass model trains, like this 0-4-0T.

-

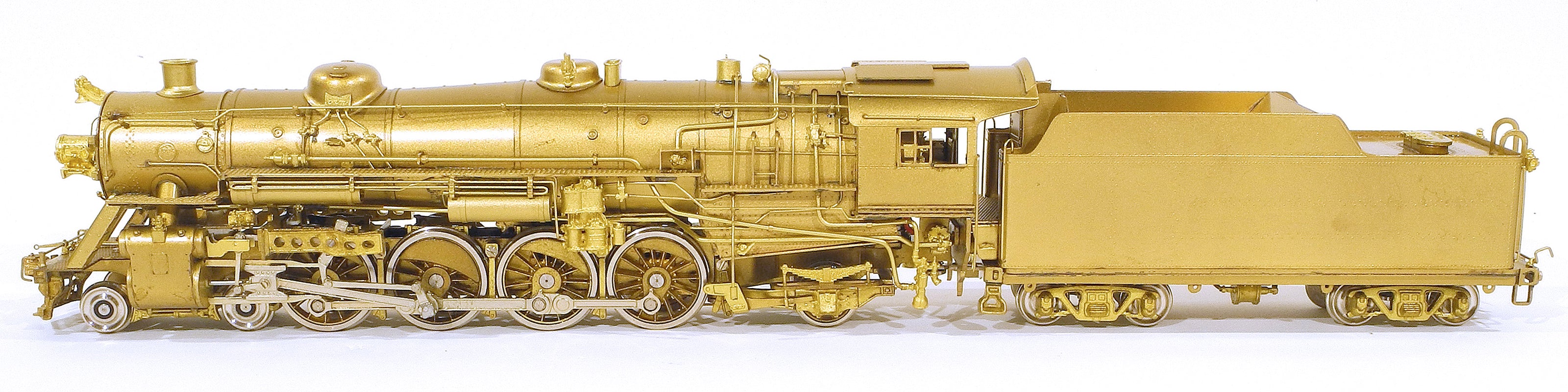

See Larger Image

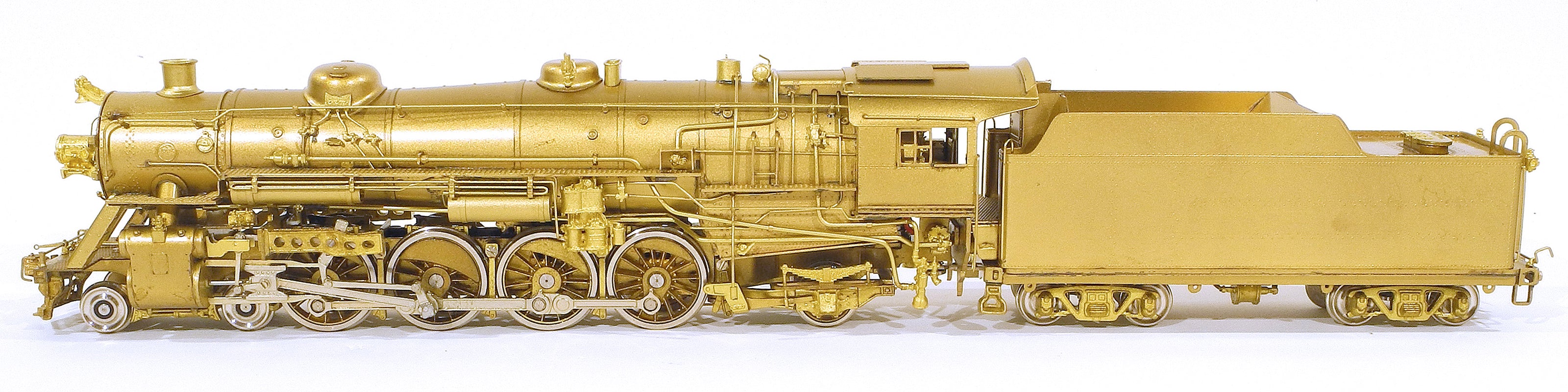

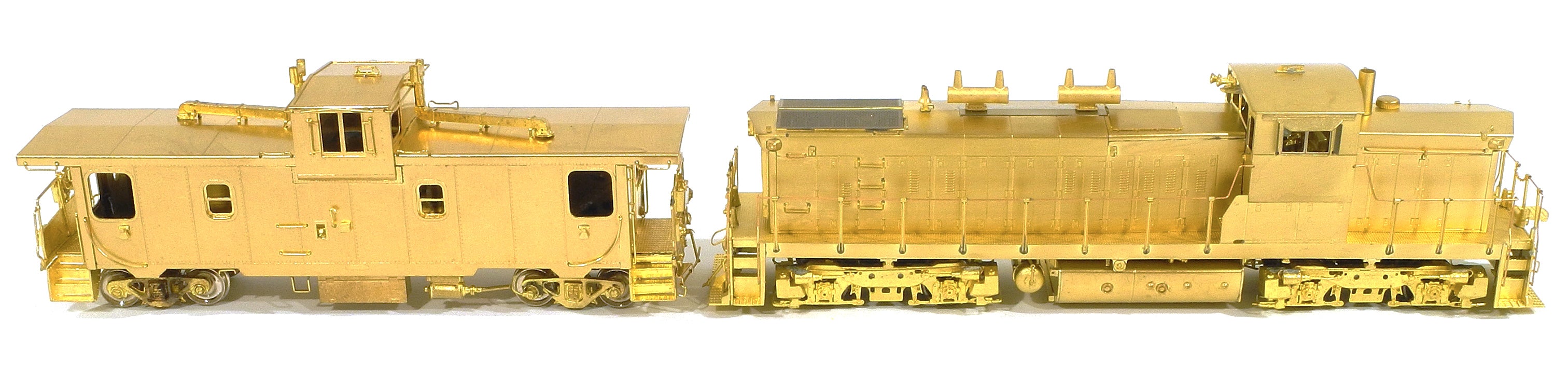

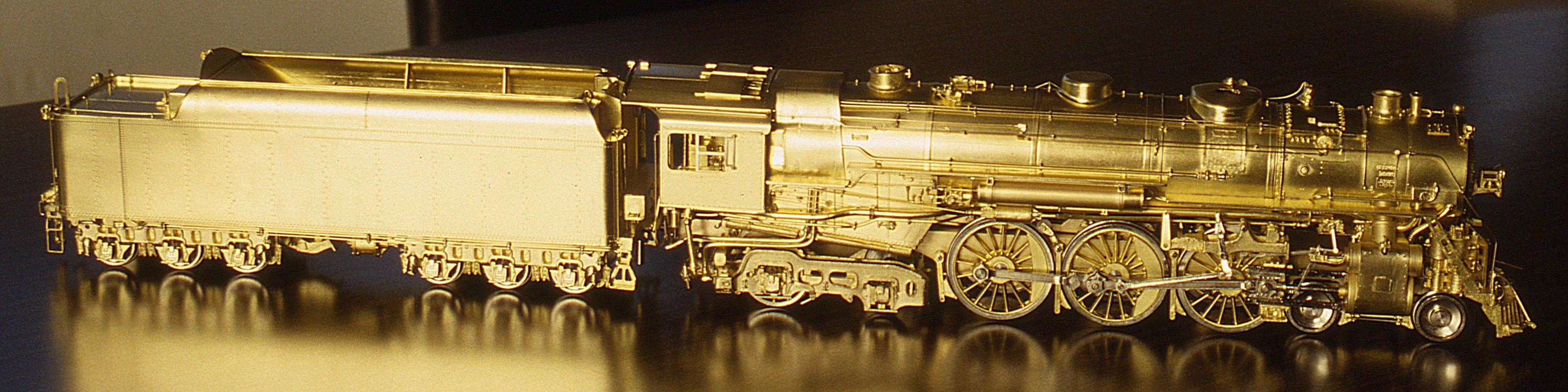

See Larger ImageWe also show examples of how we take 50-year old tarnished models and make them look brand new again.

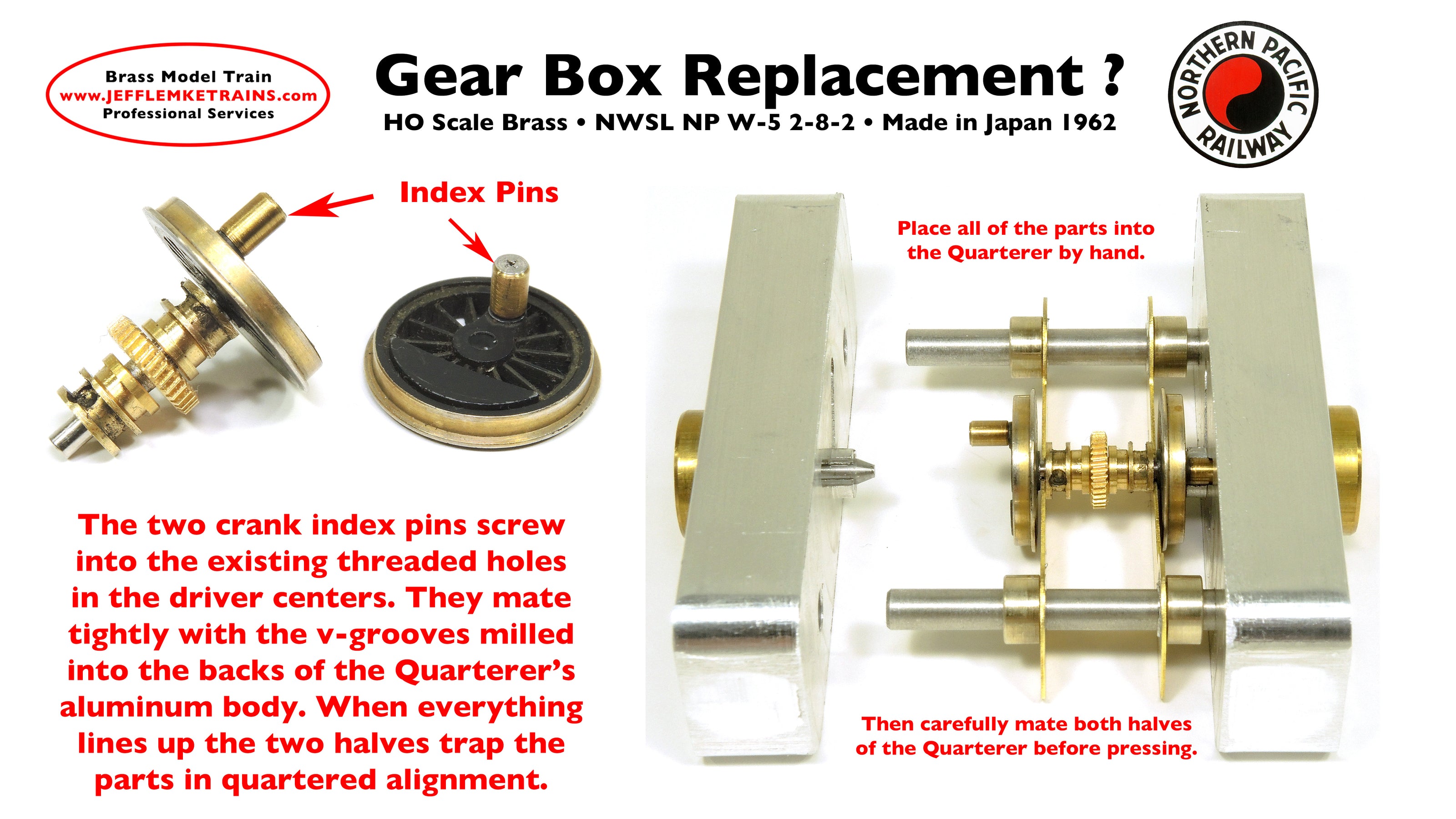

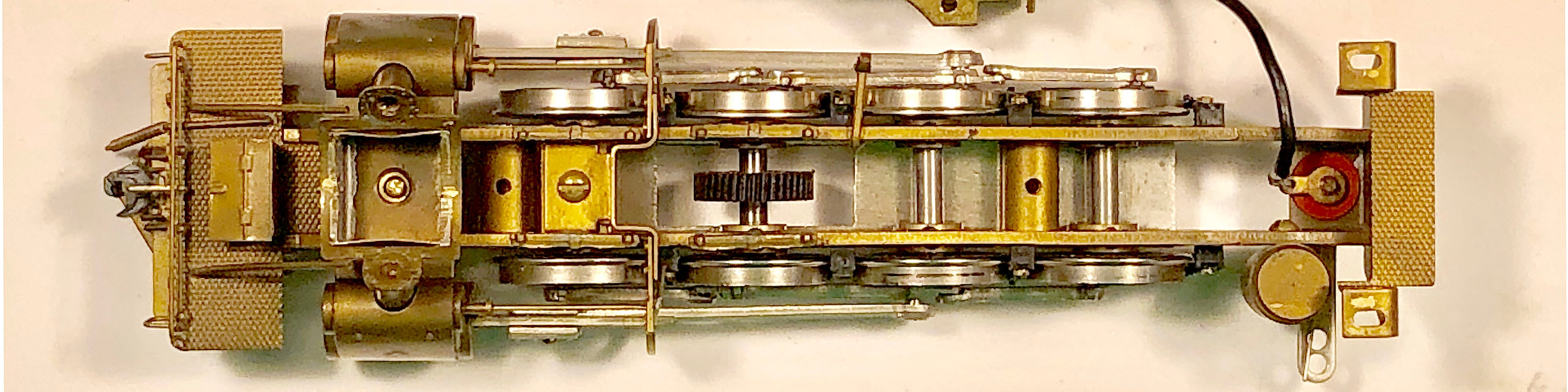

Gear Box Replacements and Re-Quartering Drivers

-

See Larger Image

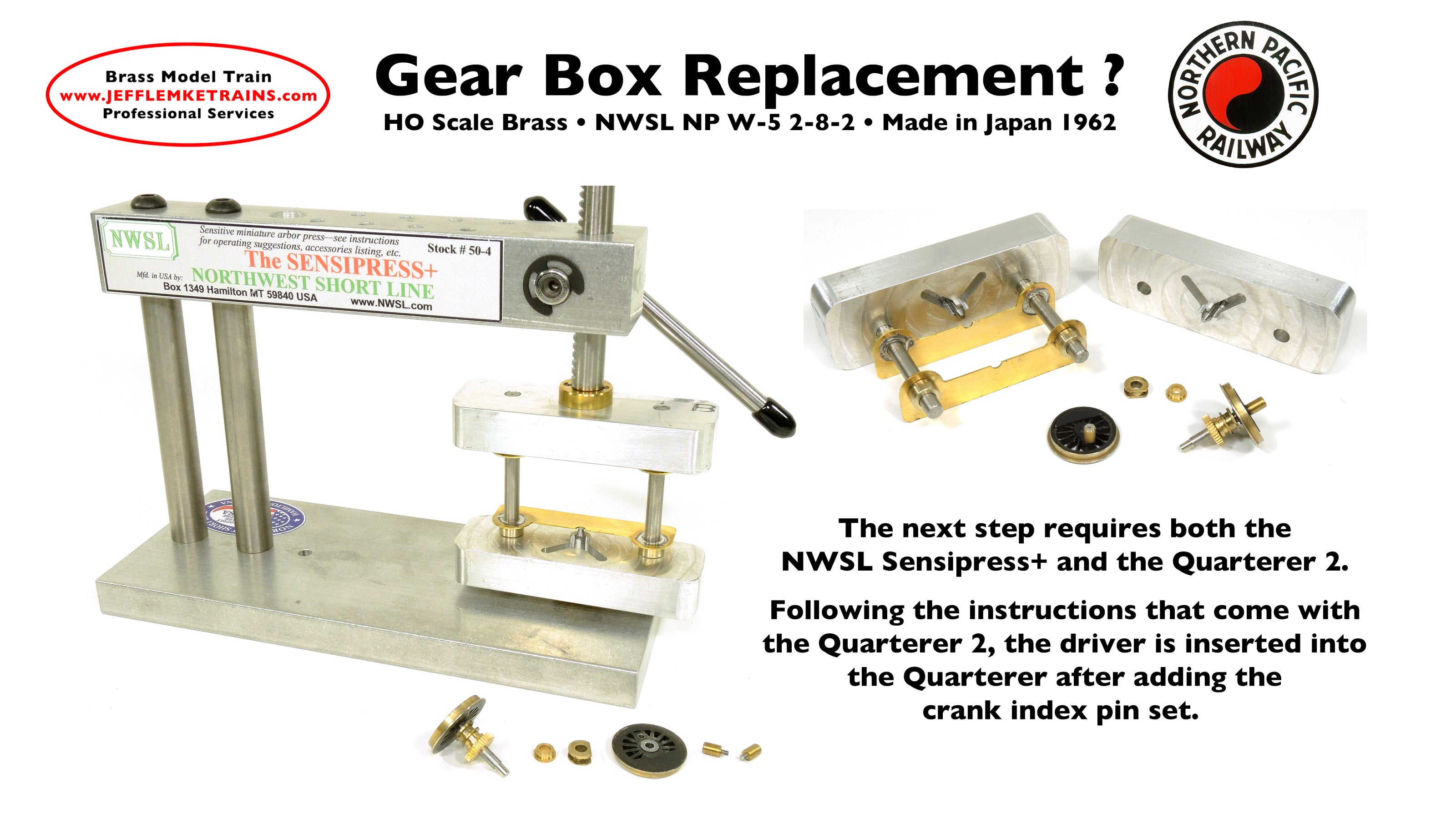

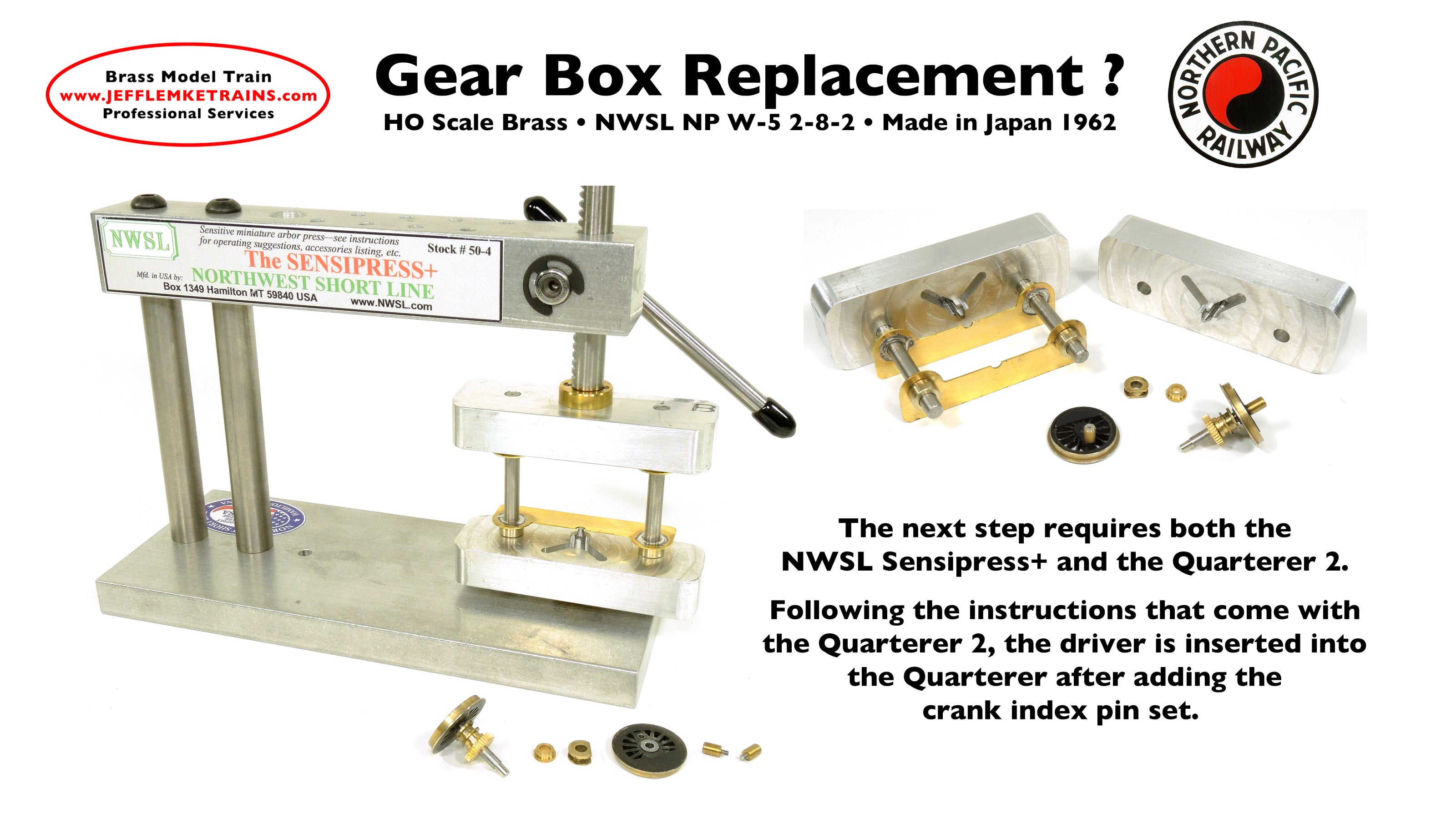

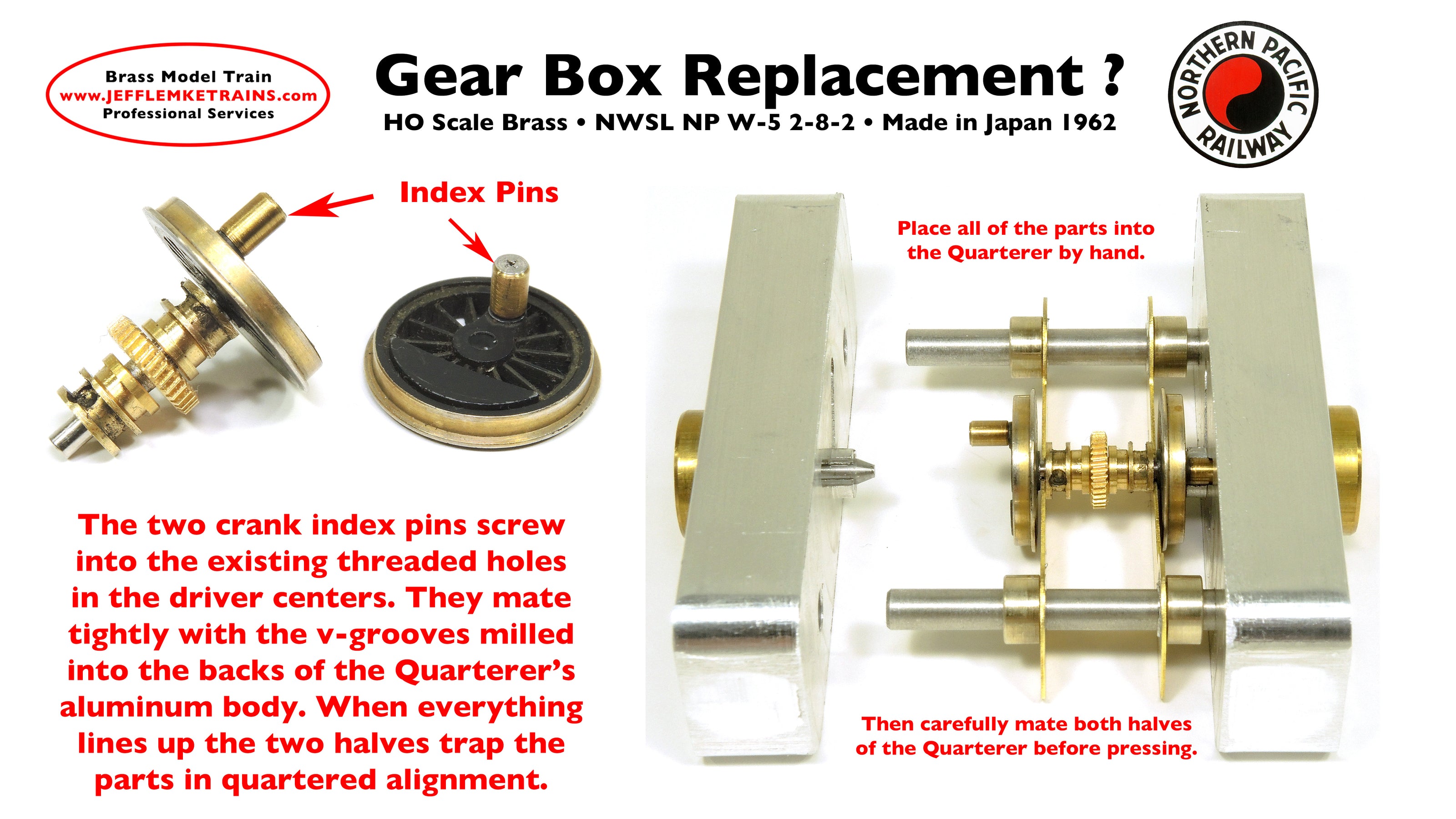

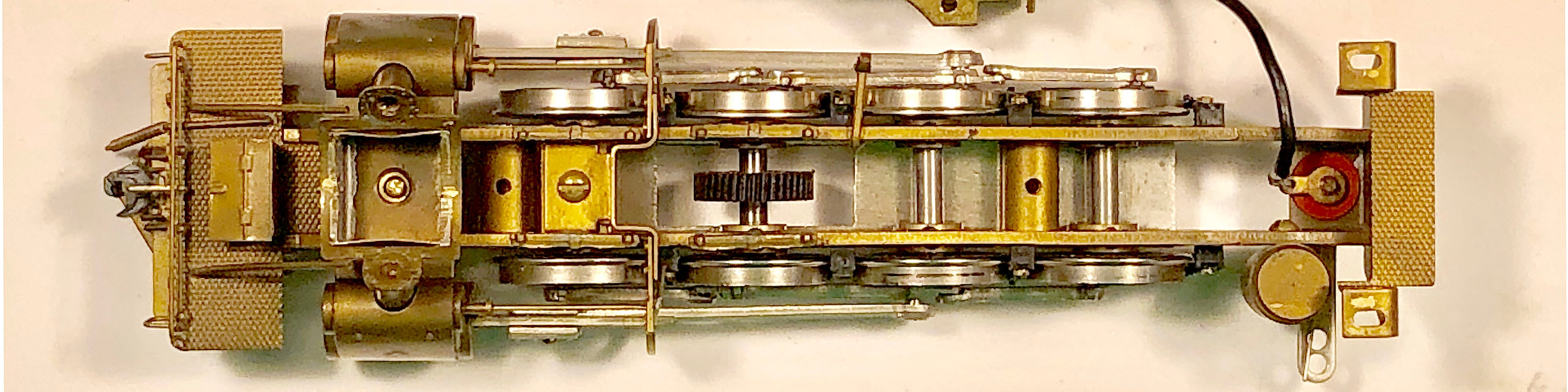

See Larger ImageReplacing gear boxes and quartering drivers in brass steam locomotives must be done carefully, with great patience.

-

See Larger Image

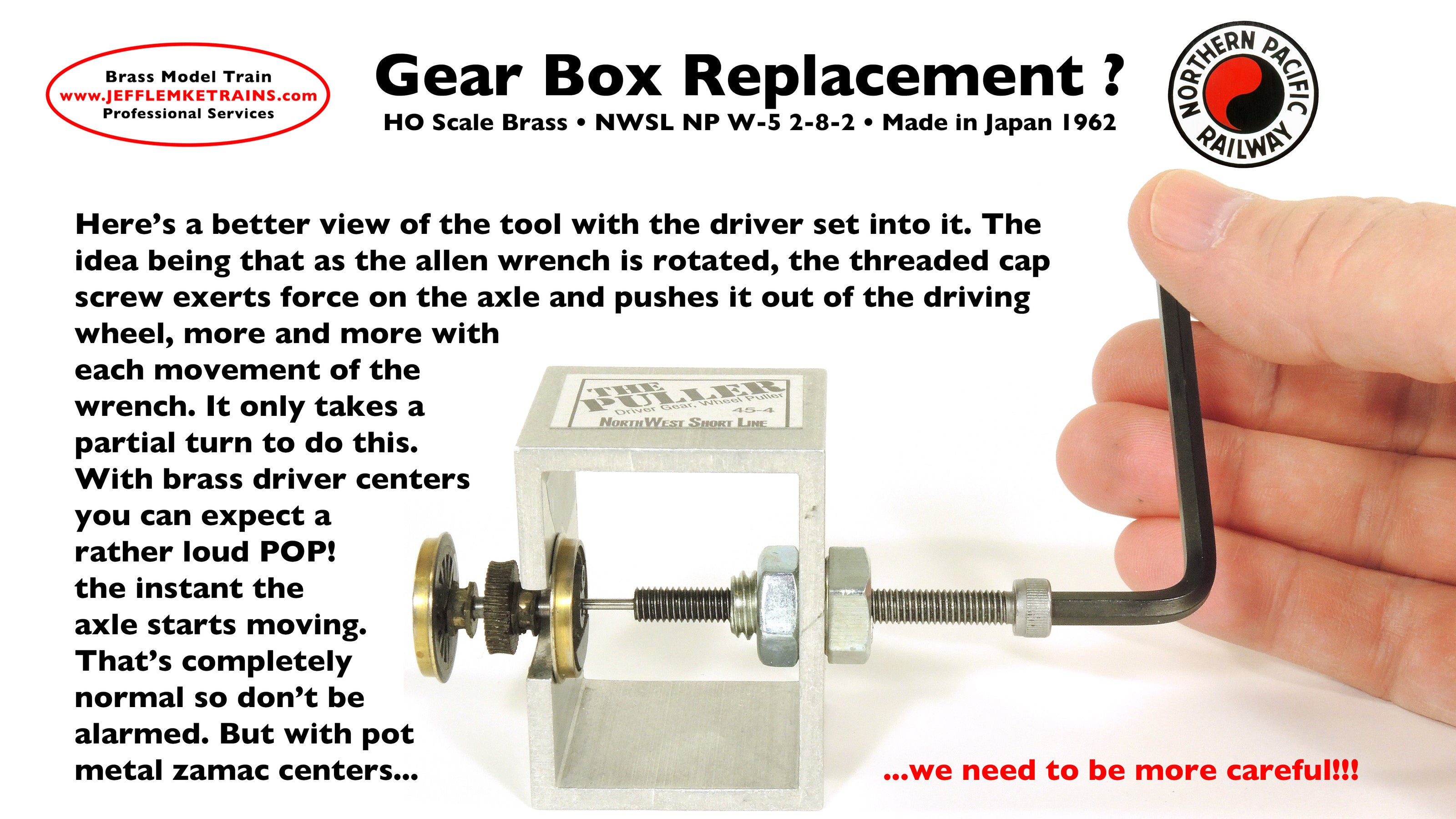

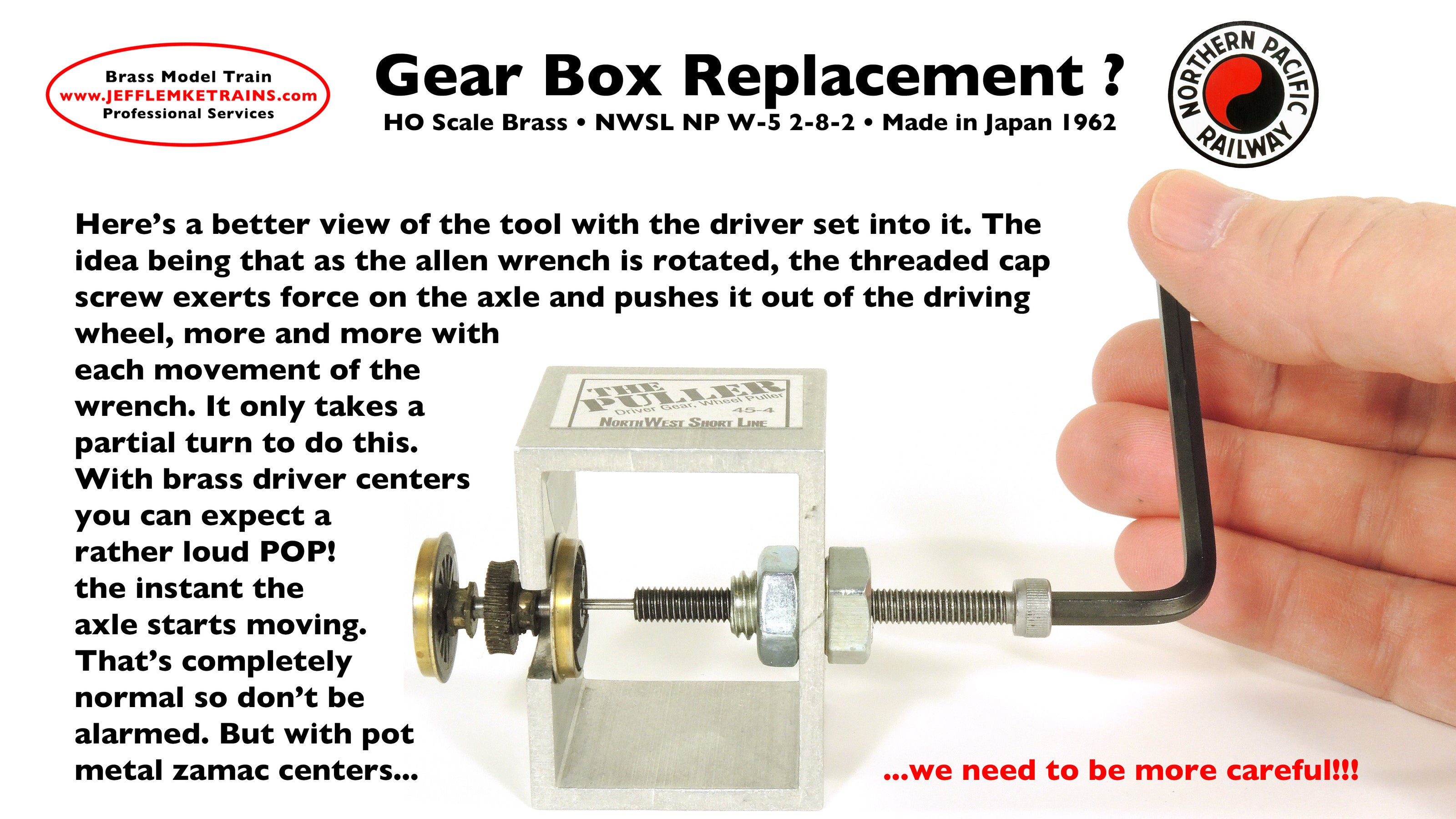

See Larger ImageKnowing what to expect before removing drivers from axles is essential to a successful gear box installation.

-

See Larger Image

See Larger ImageOur Facebook story on gear box replacements shows exactly how we do this work to make models run better.

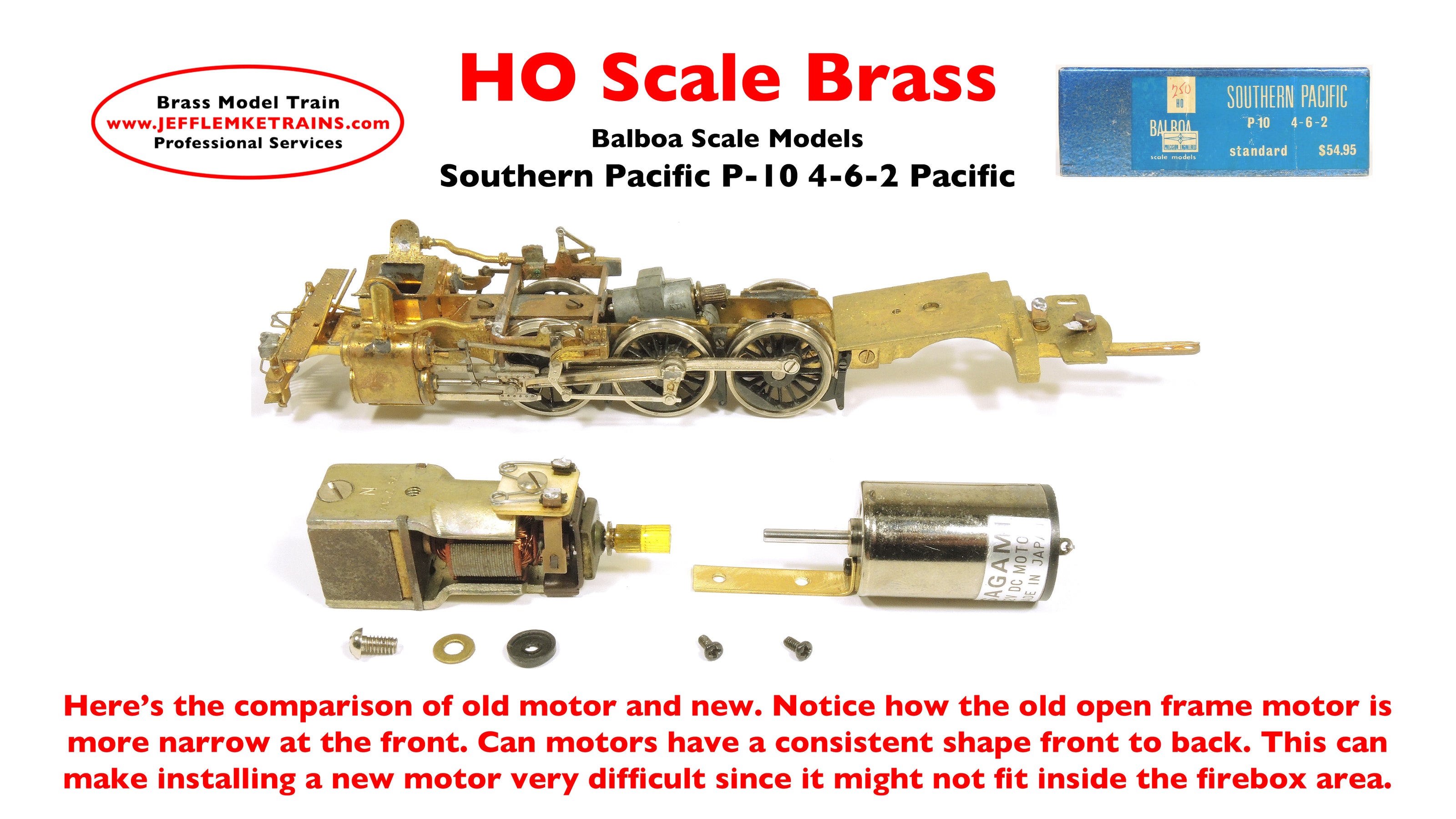

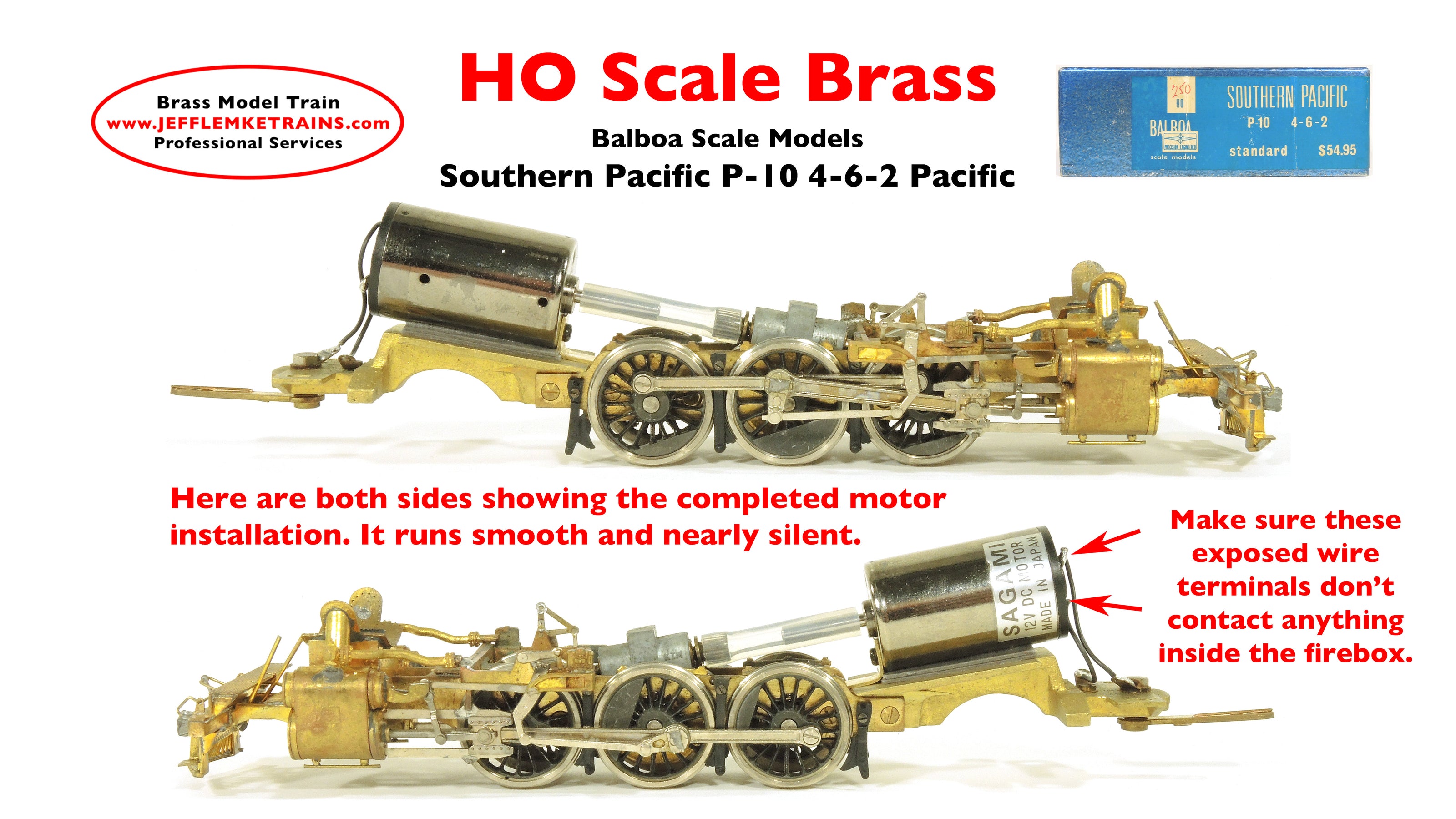

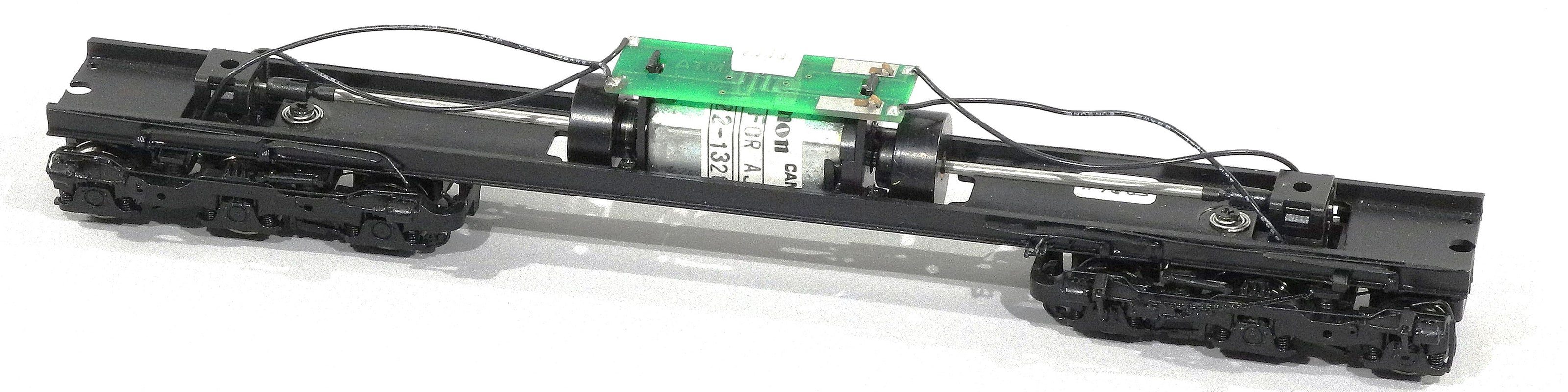

Re-Motoring Older Brass Locomotives

-

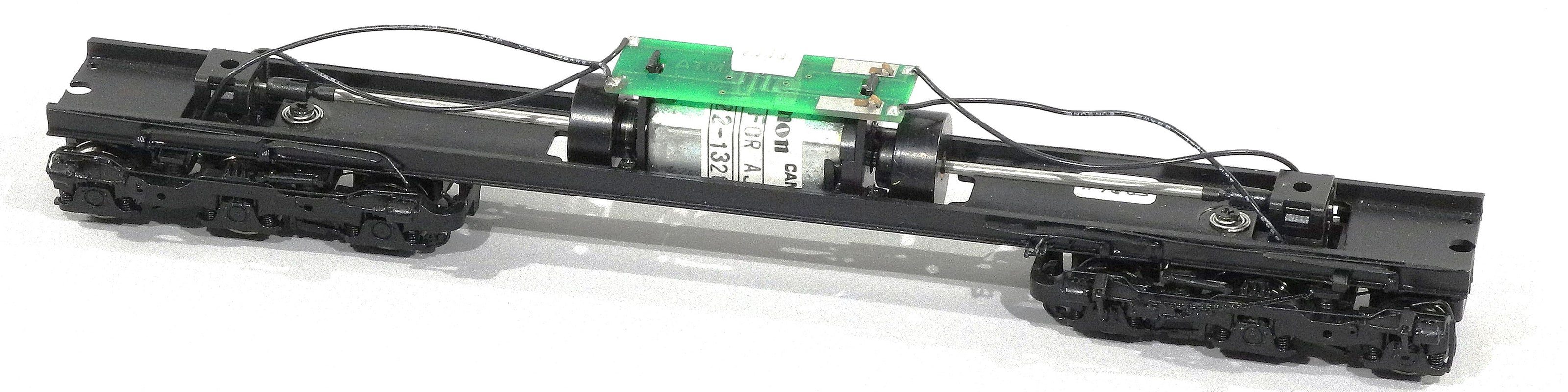

See Larger Image

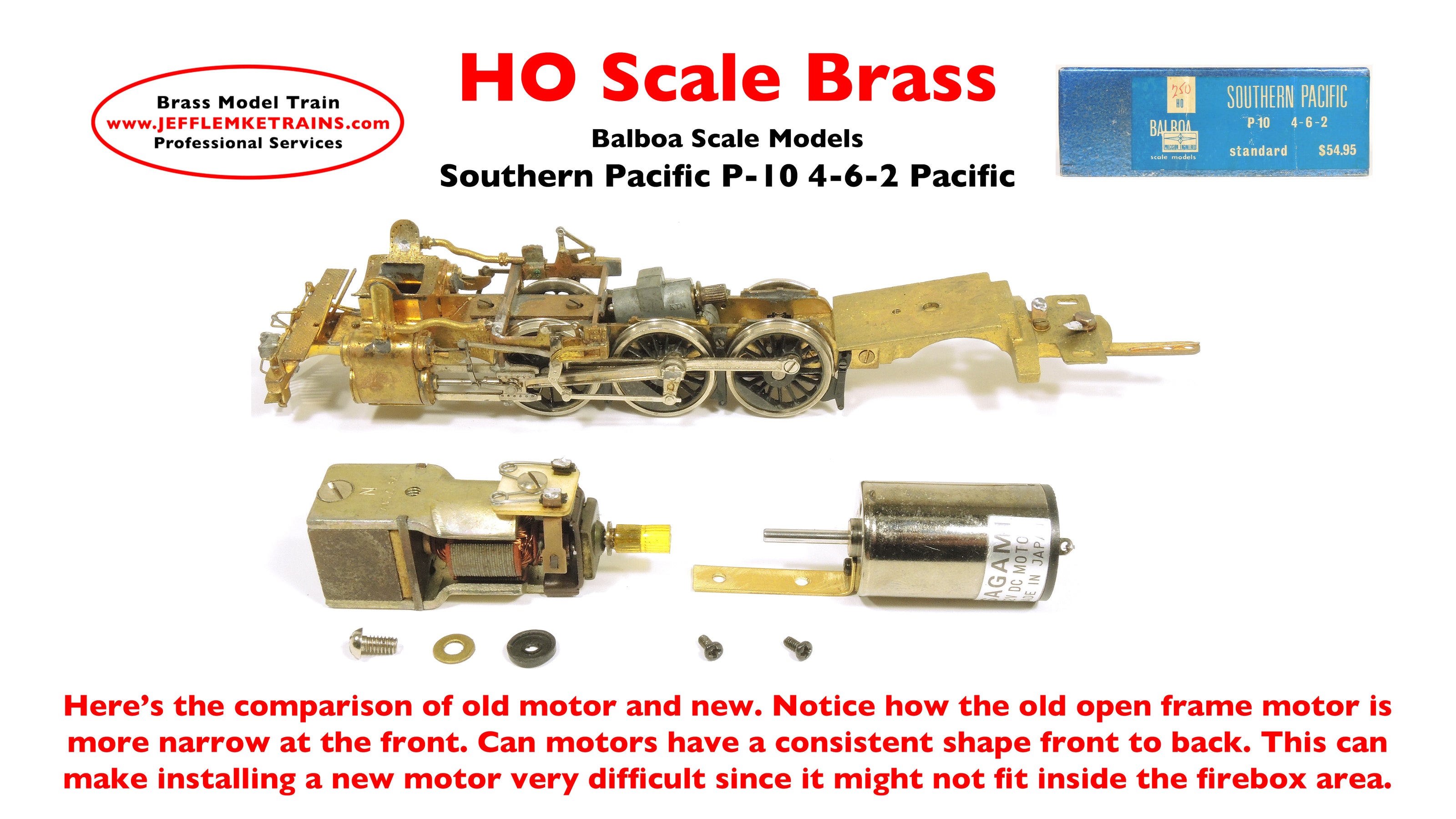

See Larger ImageOur Facebook page shows a number of examples of how we re-motor older brass models to be DCC compatible.

-

See Larger Image

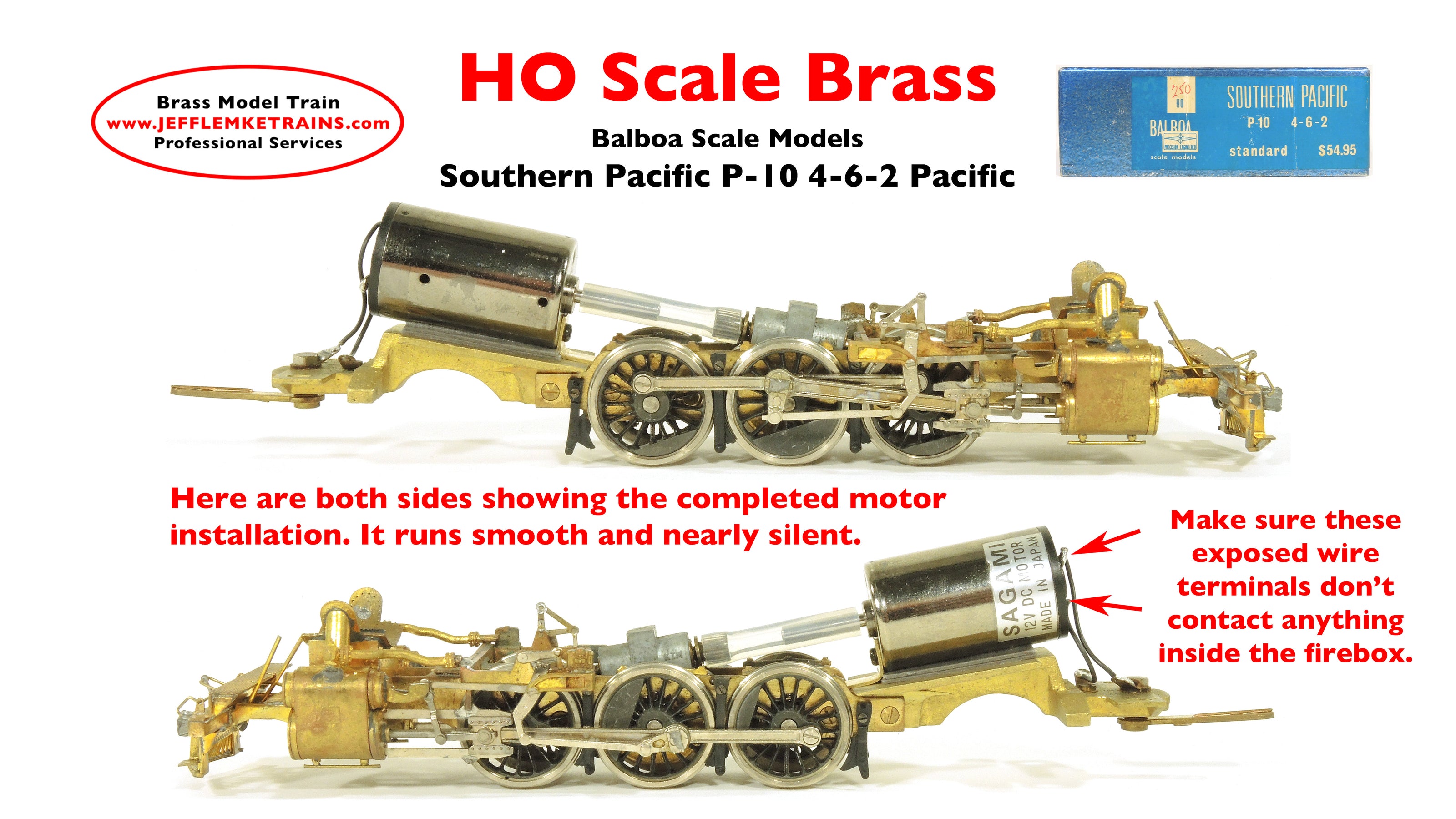

See Larger ImageWhat most folks don't realize is that new motors usually require scratch-building new motor mounts to fit their model.

-

See Larger Image

See Larger ImageWhen new motors are correctly installed and aligned with the gear box, the drives routinely run smooth and very quiet.

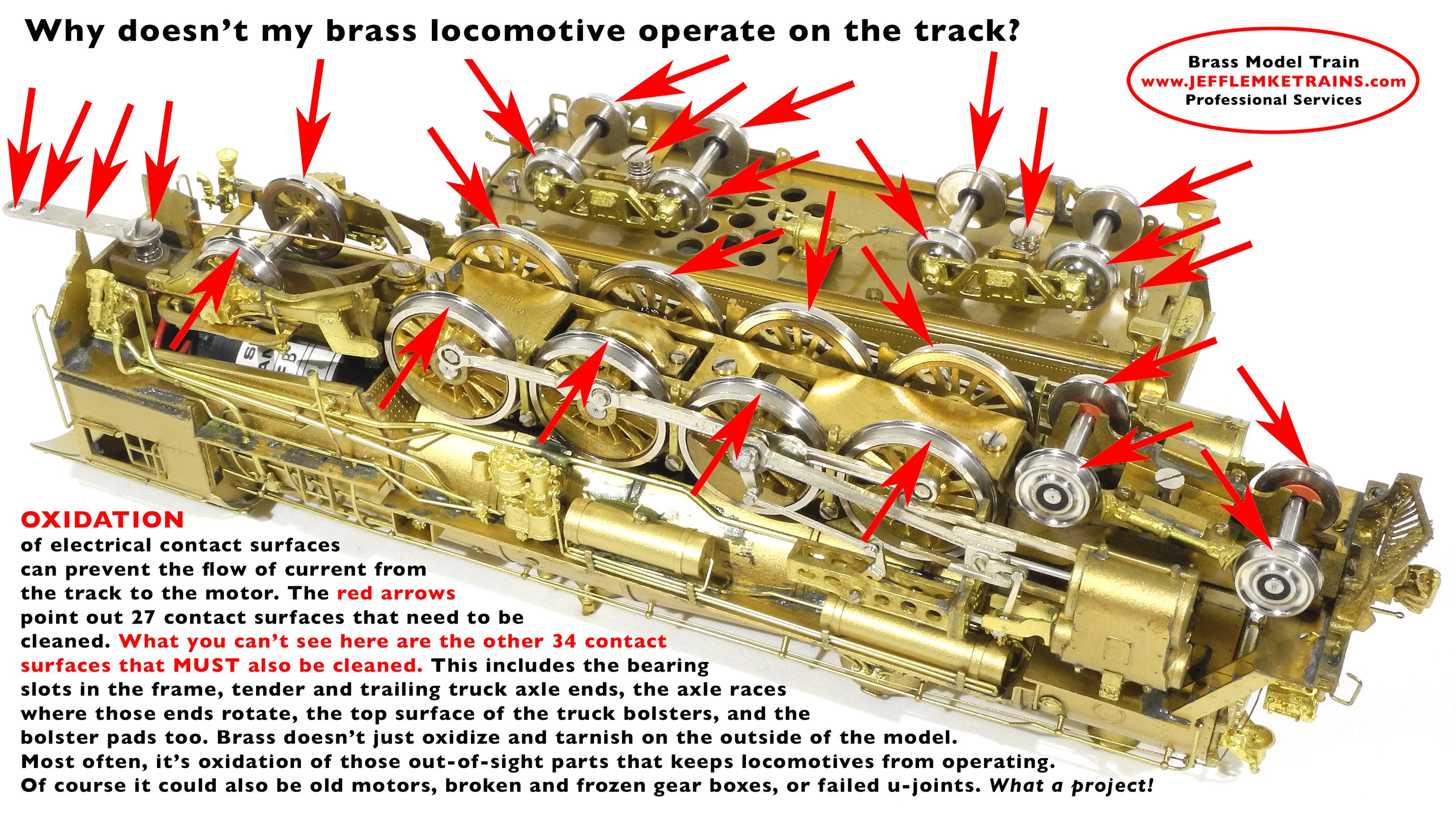

Diagnosing Serious Brass Issues

-

See Larger Image

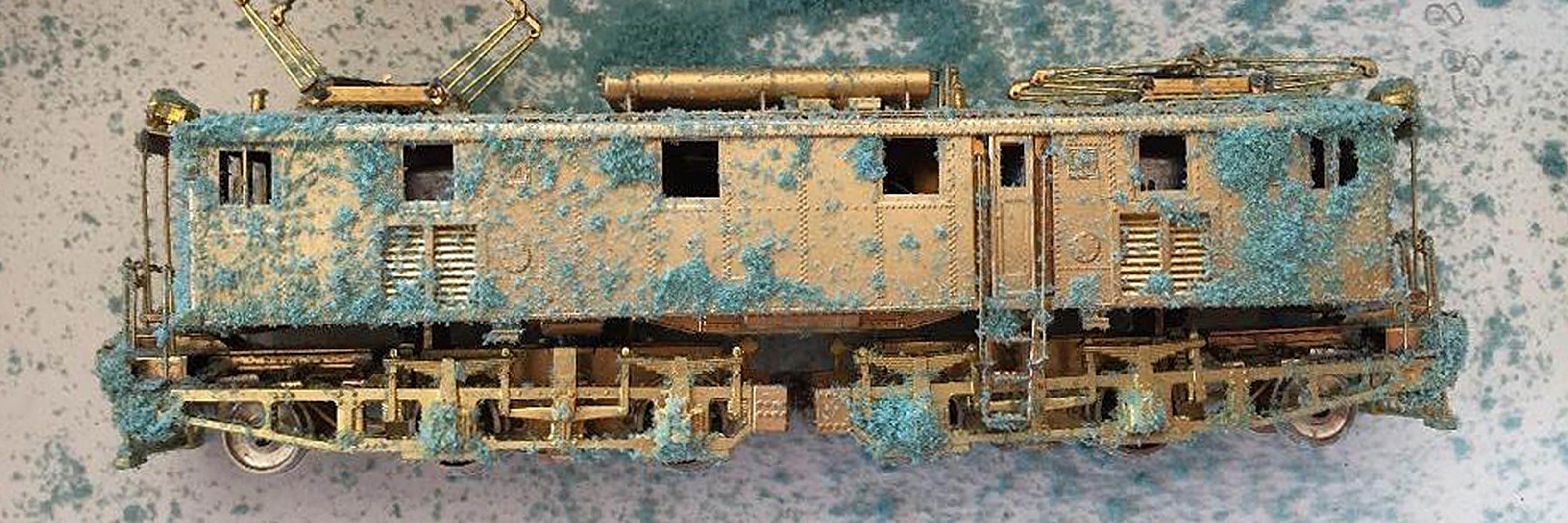

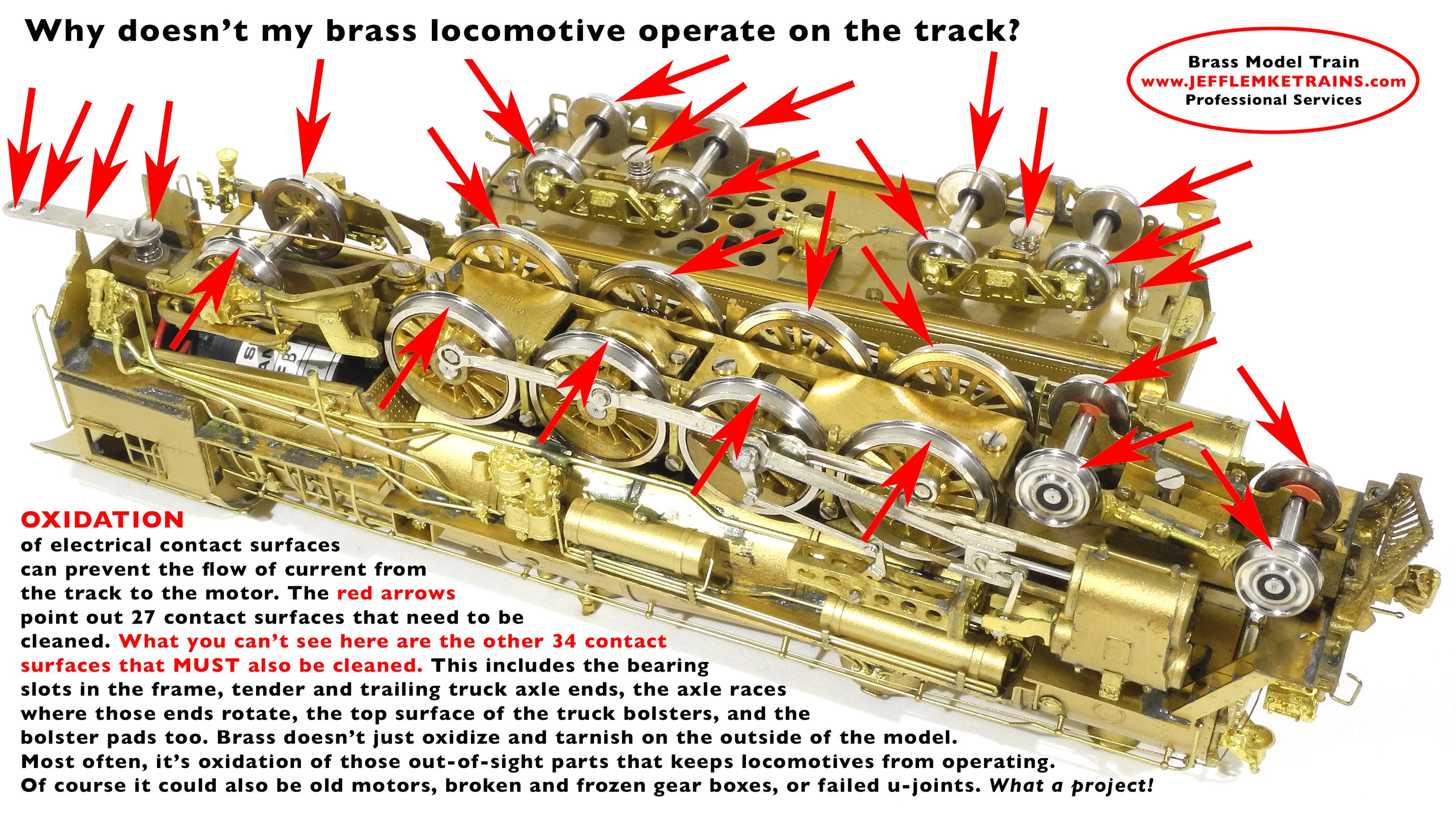

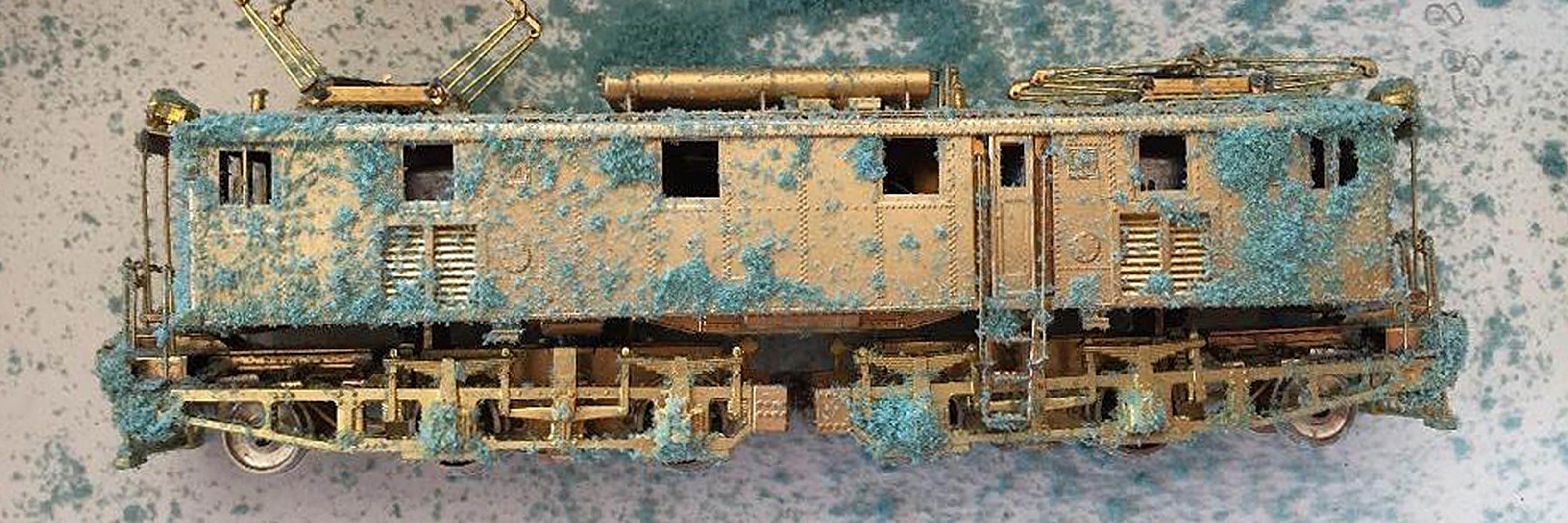

See Larger ImageMost older brass models don't run now because of OXIDATION. This model had 61 surfaces that needed to be cleaned.

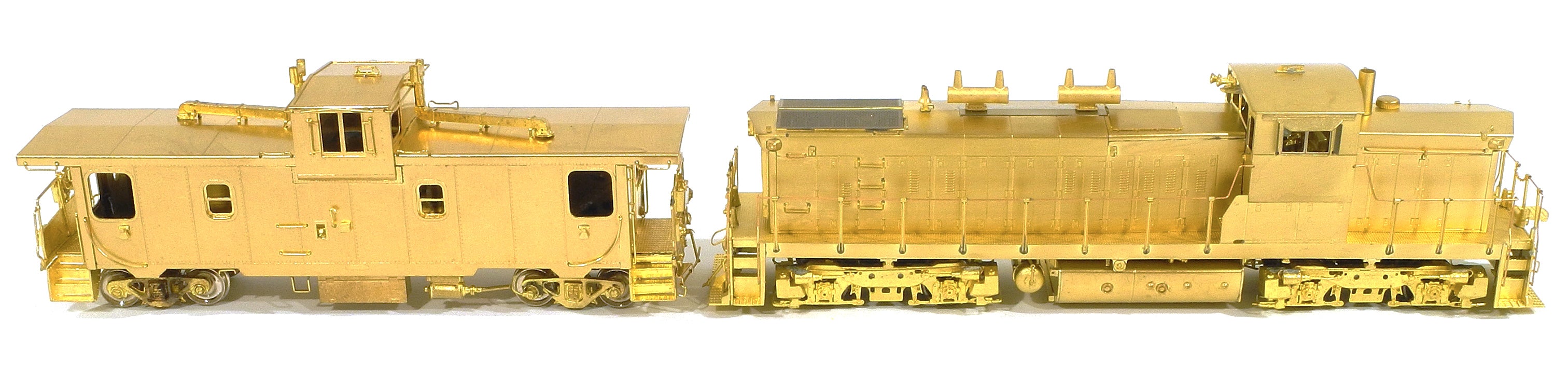

-

See Larger Image

See Larger ImageTARNISH is what turns brass brown. We use a chemical and blast-media formula to restore brass to its original luster.

-

See Larger Image

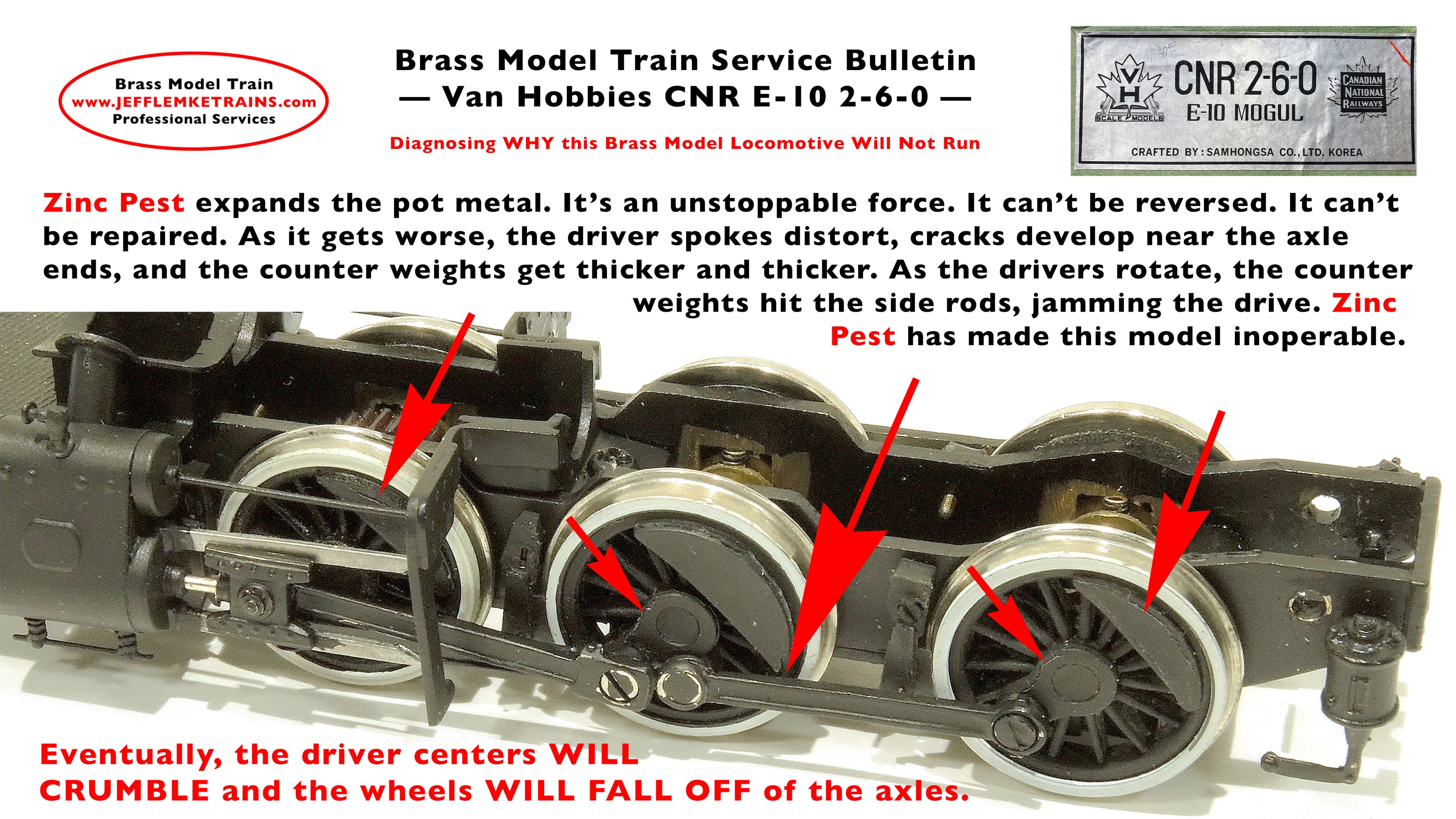

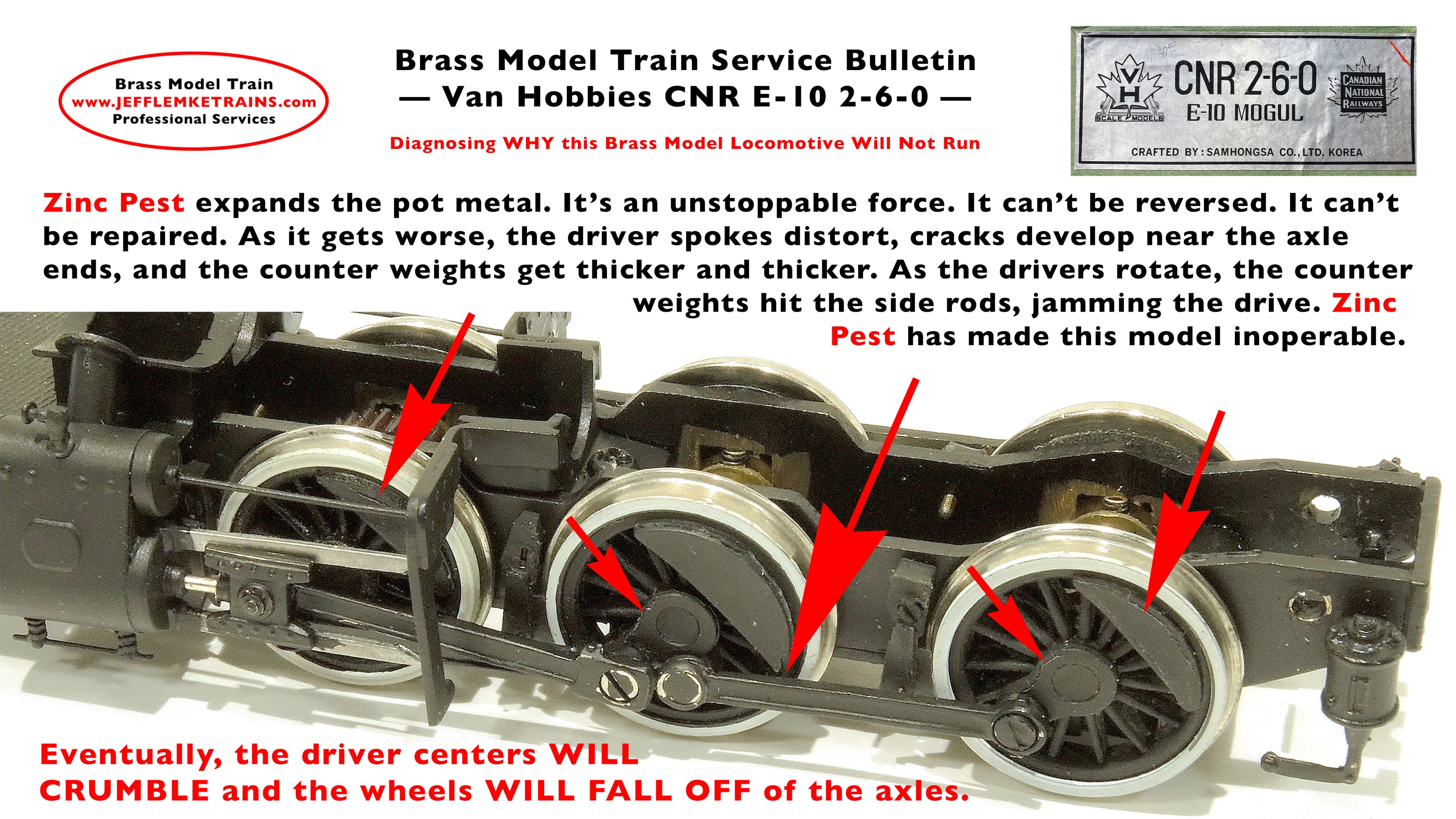

See Larger ImageZINC PEST can effect any model's cast zinc parts like driver centers and gear boxes. This CANNOT be repaired!

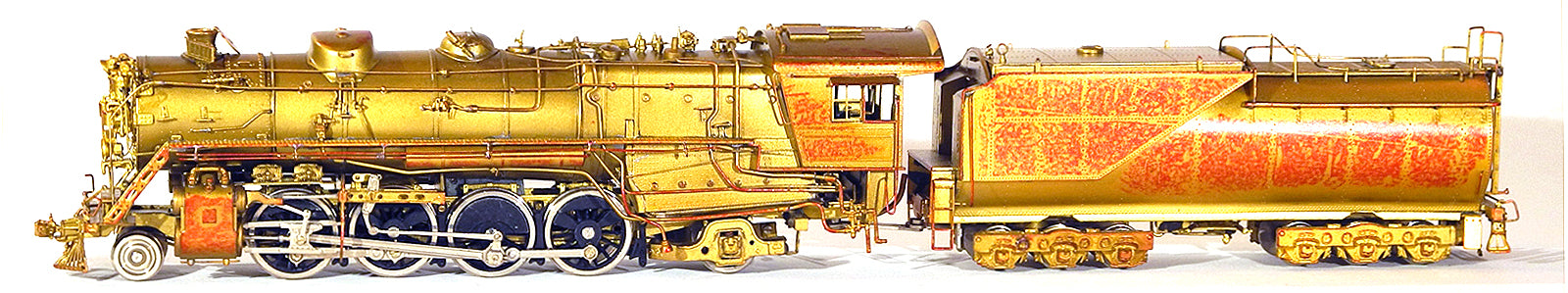

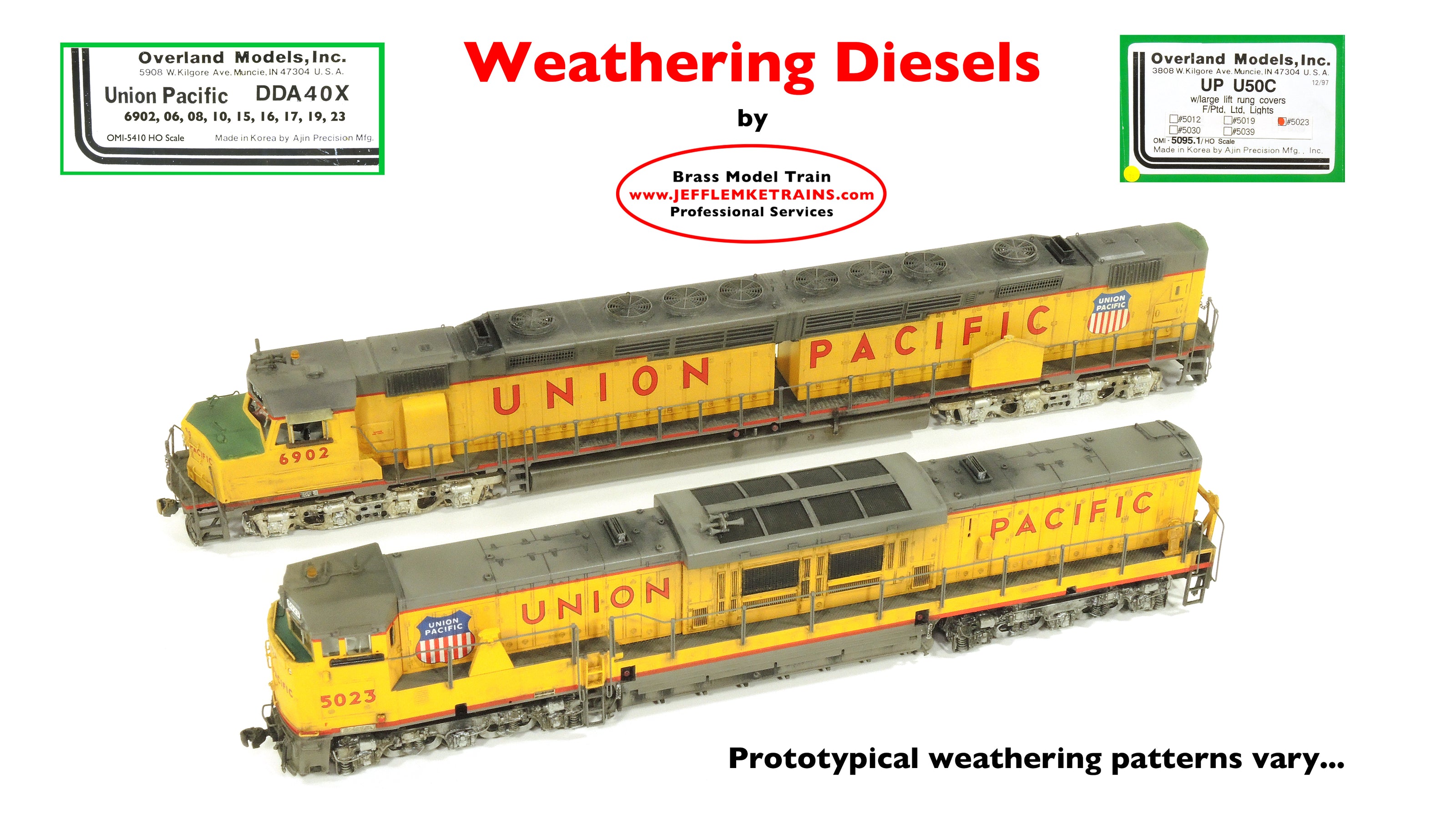

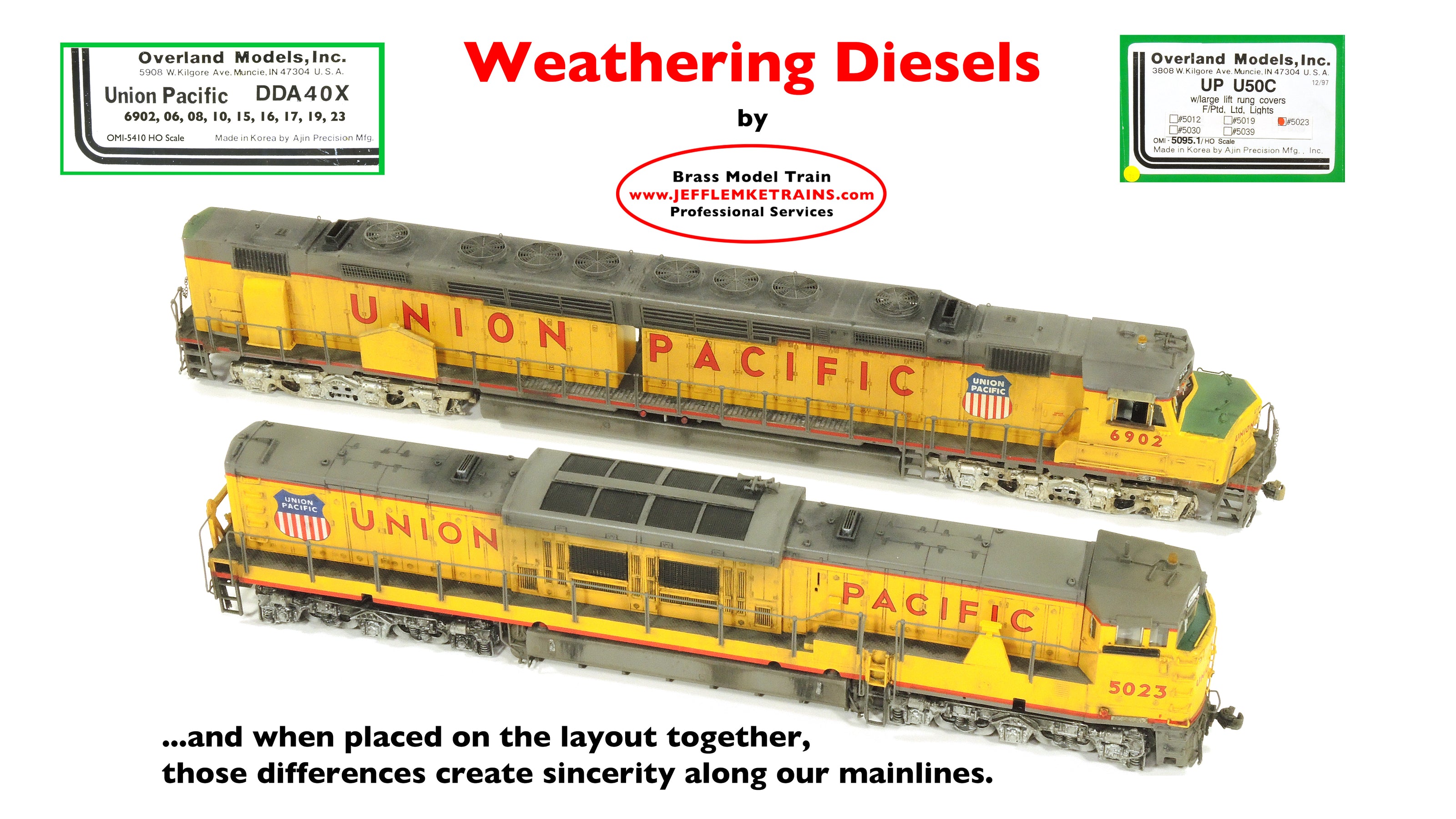

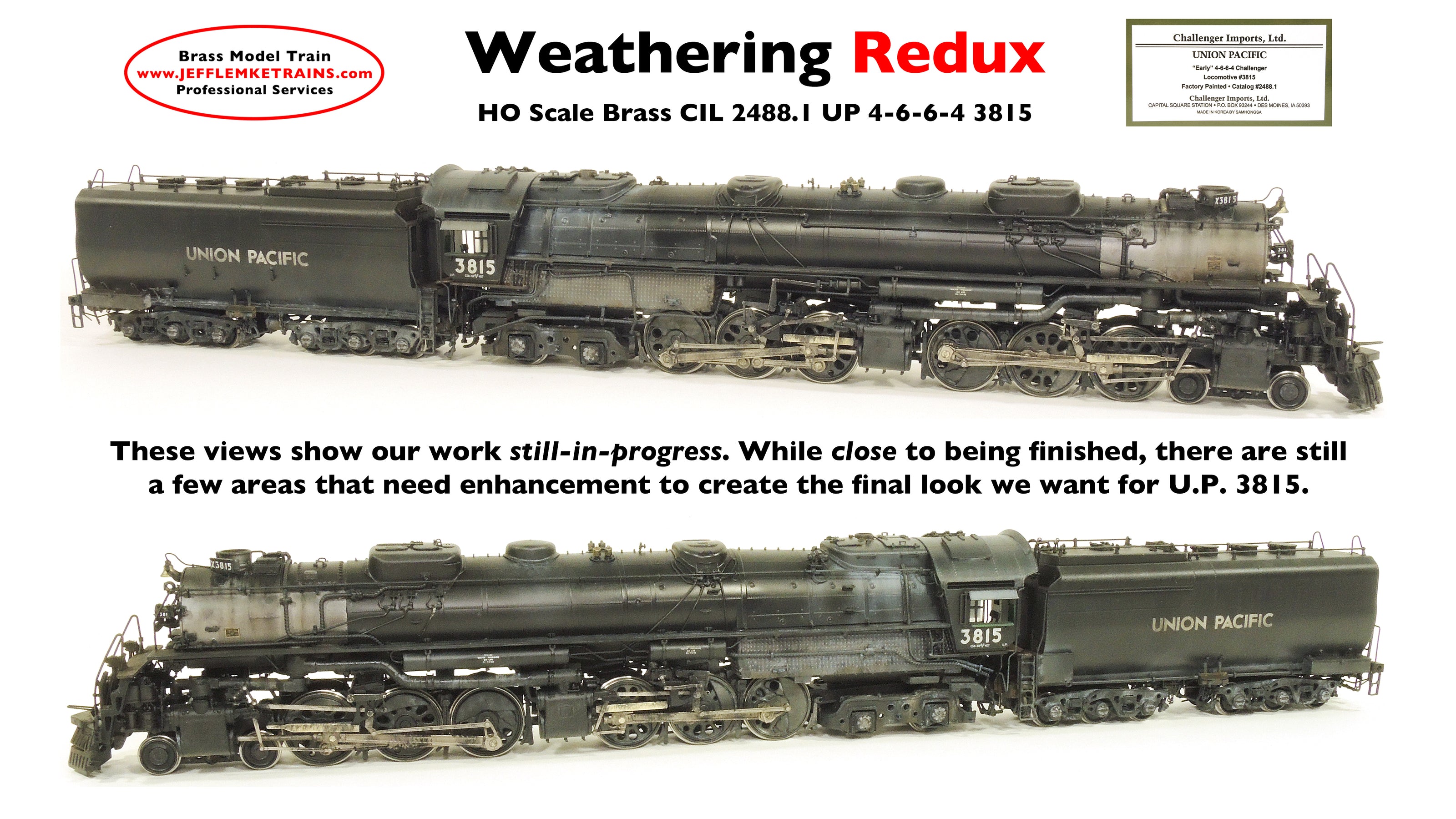

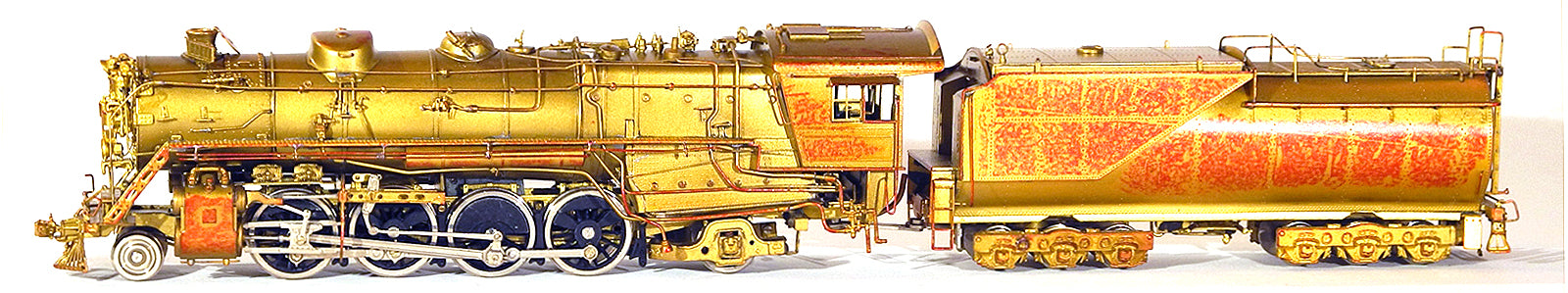

Realistic Weathering of Brass Locomotive Models

-

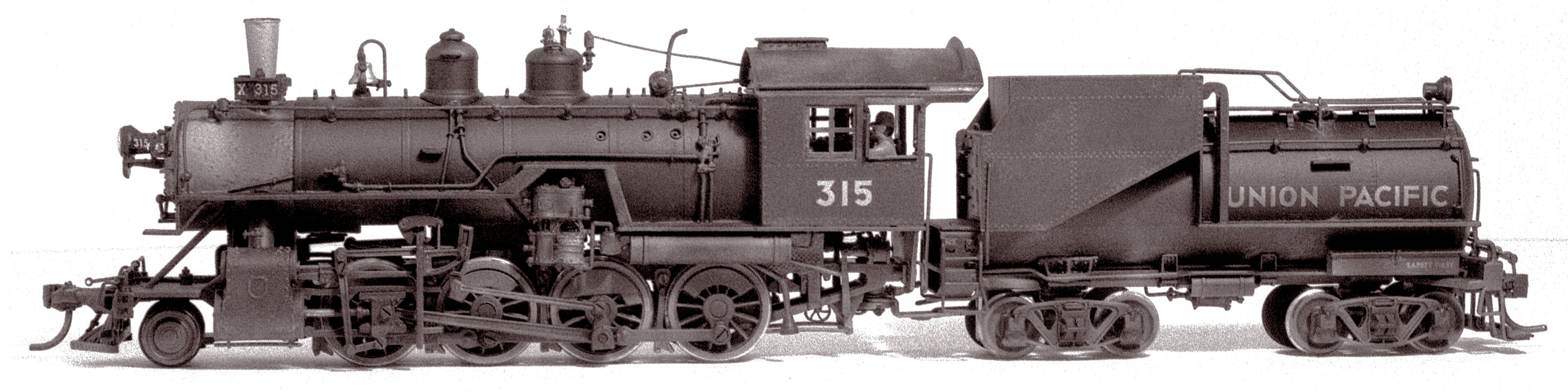

See Larger Image

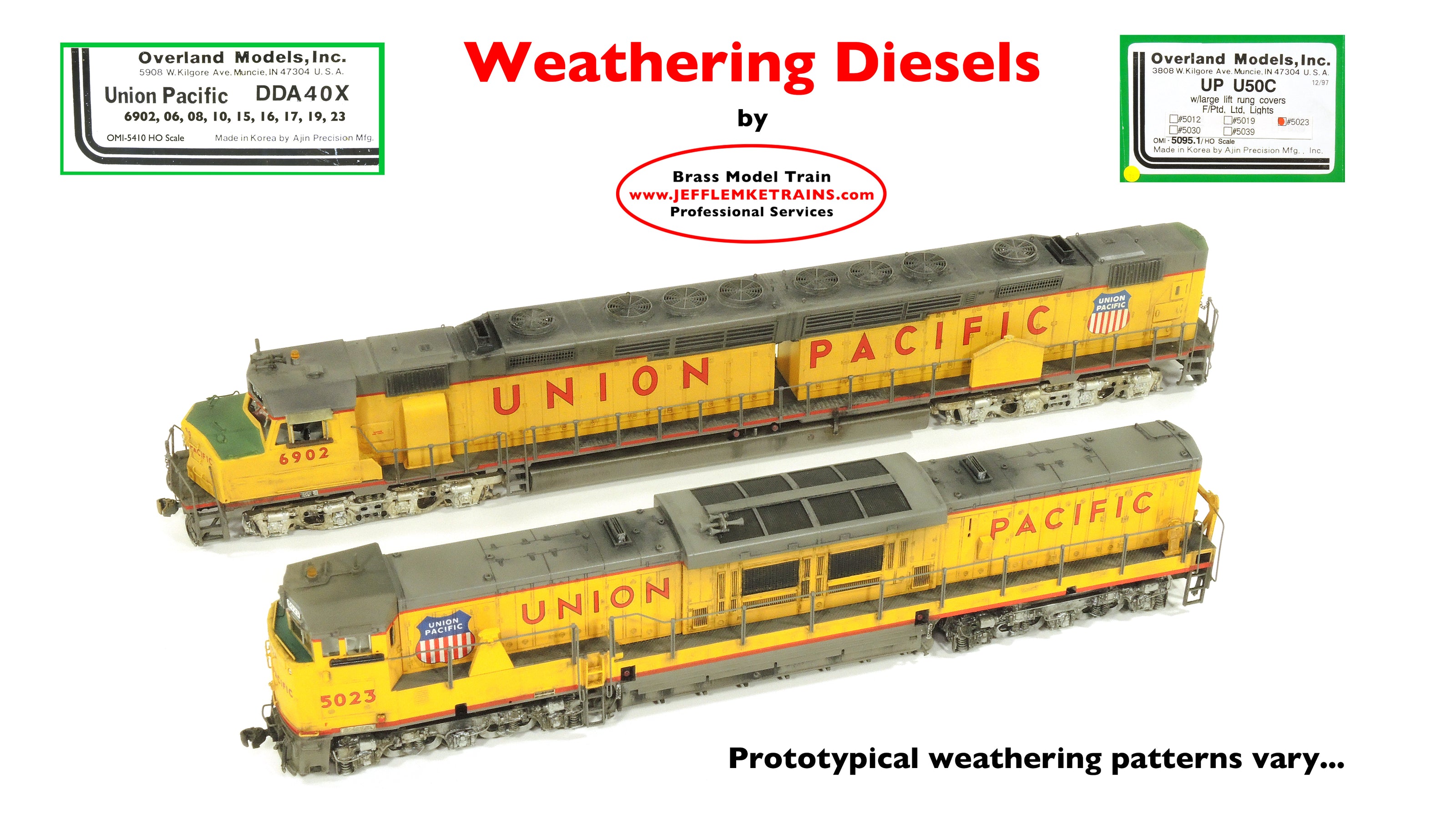

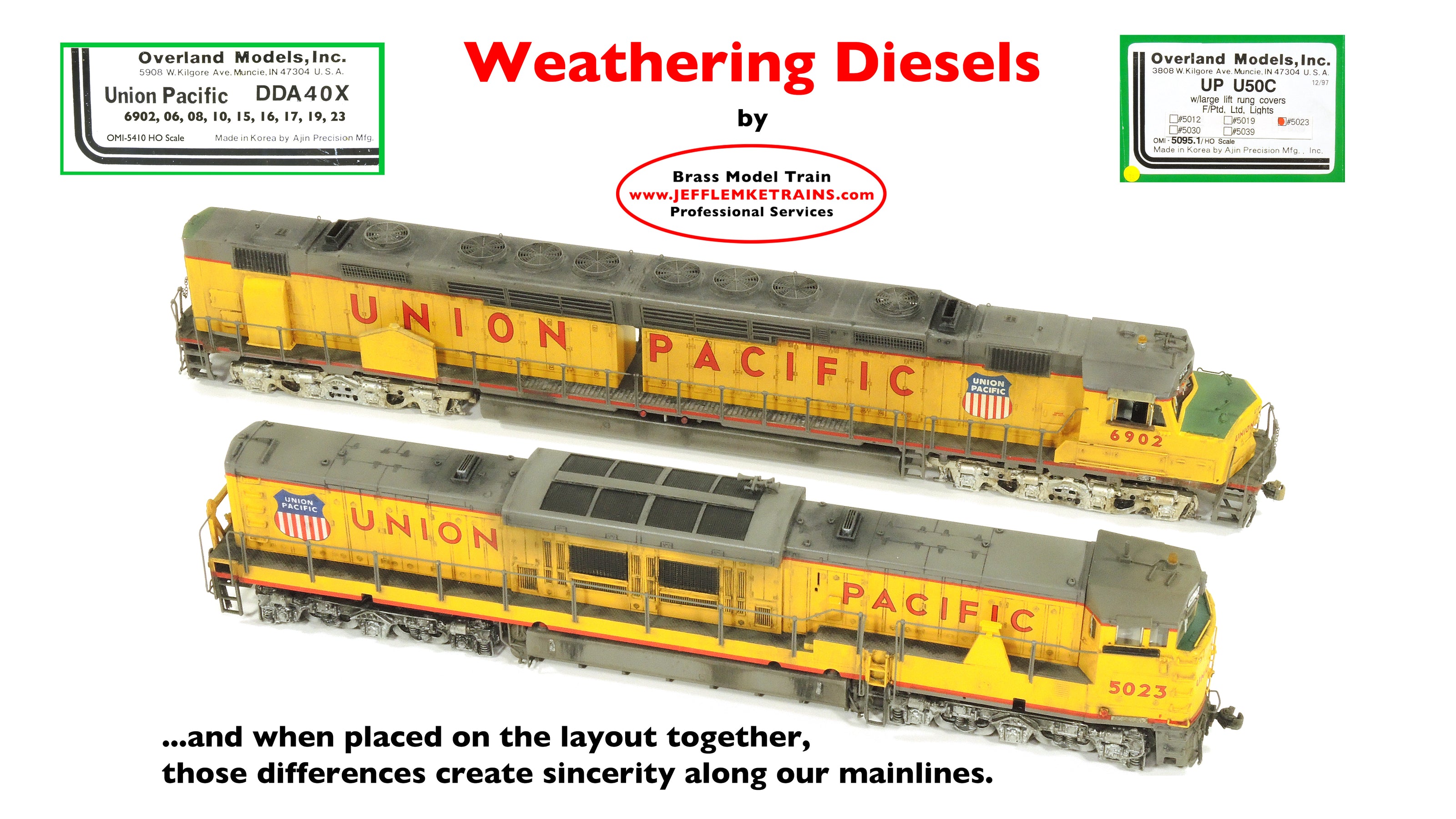

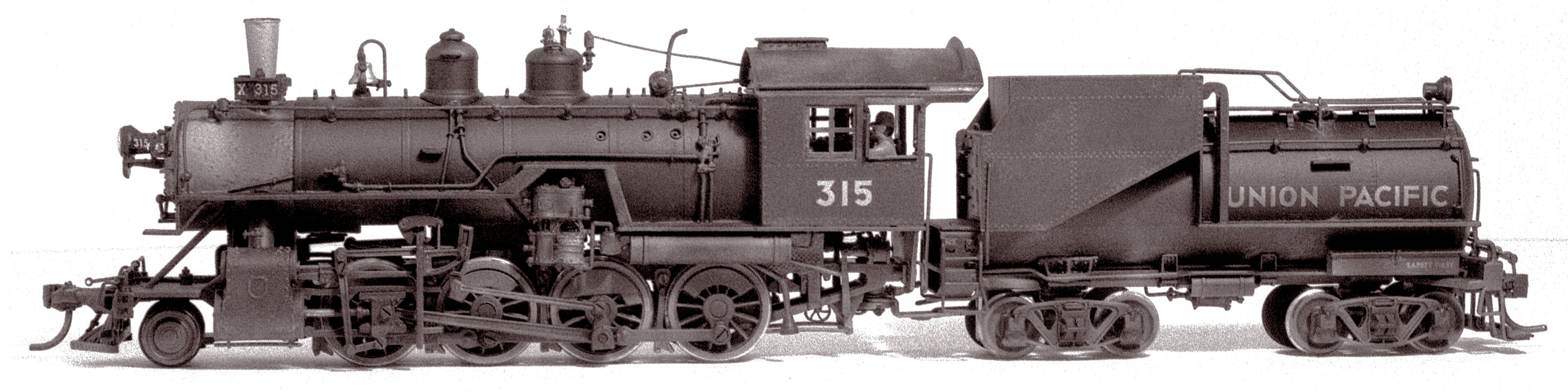

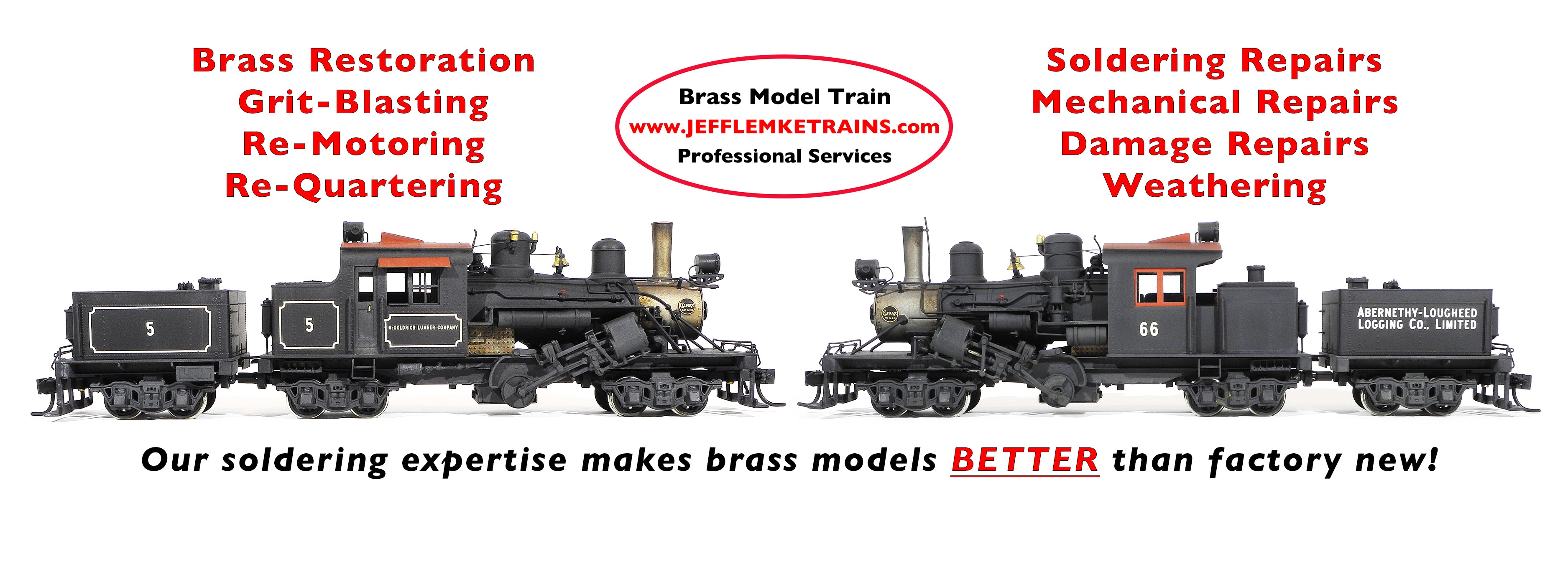

See Larger ImageThe true measure of realistic weathering is being SINCERE to the prototype. It needs to look like the real thing.

-

See Larger Image

See Larger ImageWe believe that realistic weathering goes hand in hand with the prototype fidelity of the model itself.

-

See Larger Image

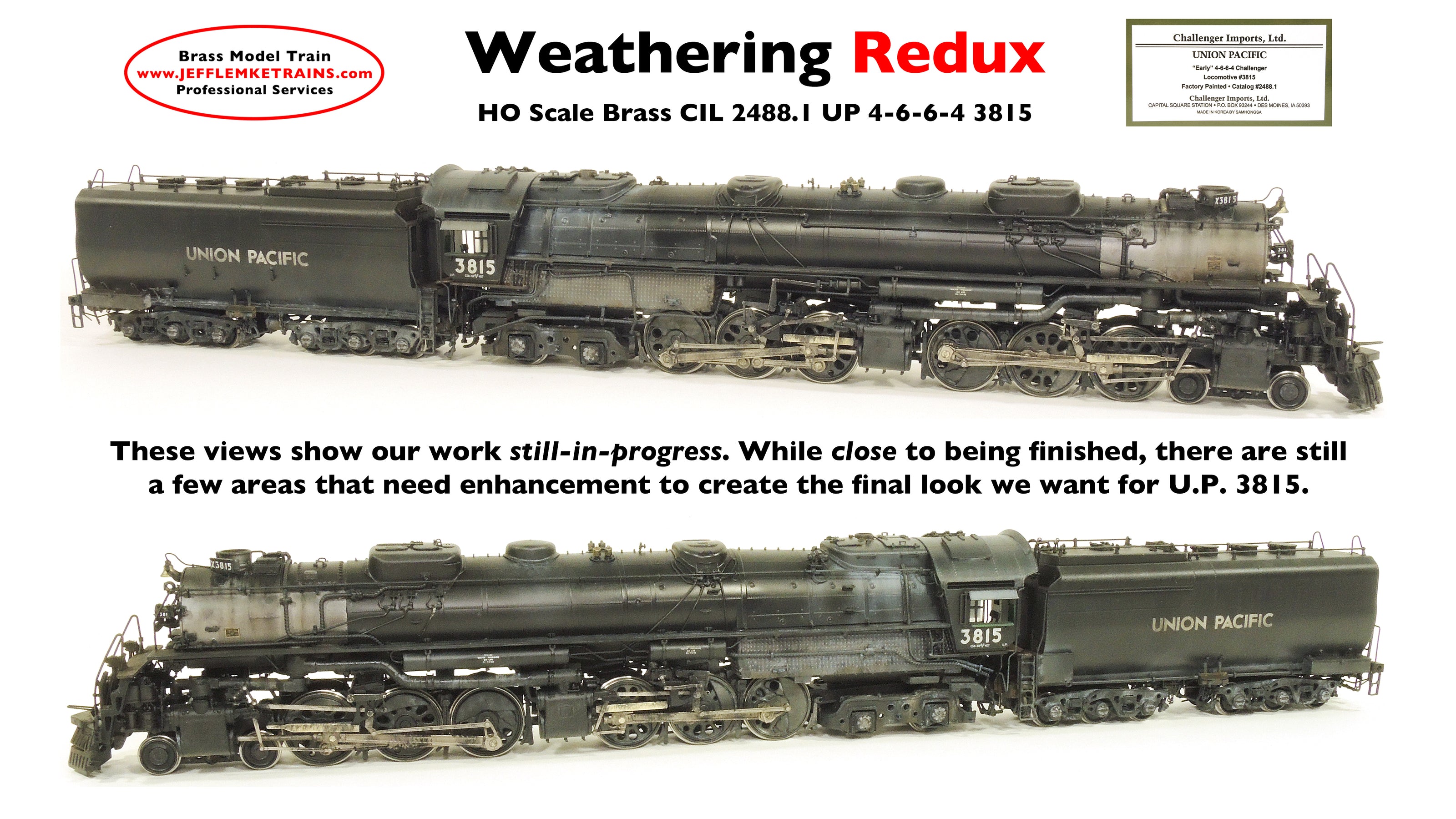

See Larger ImageMuch of our weathering work is to RE-weather previous unrealistic attempts. We'll make 'em look real.

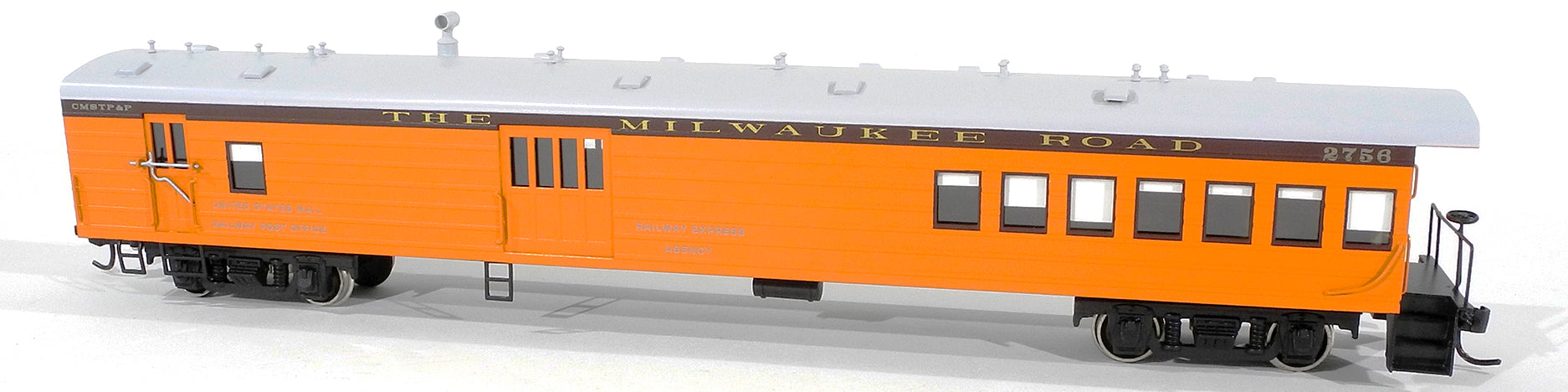

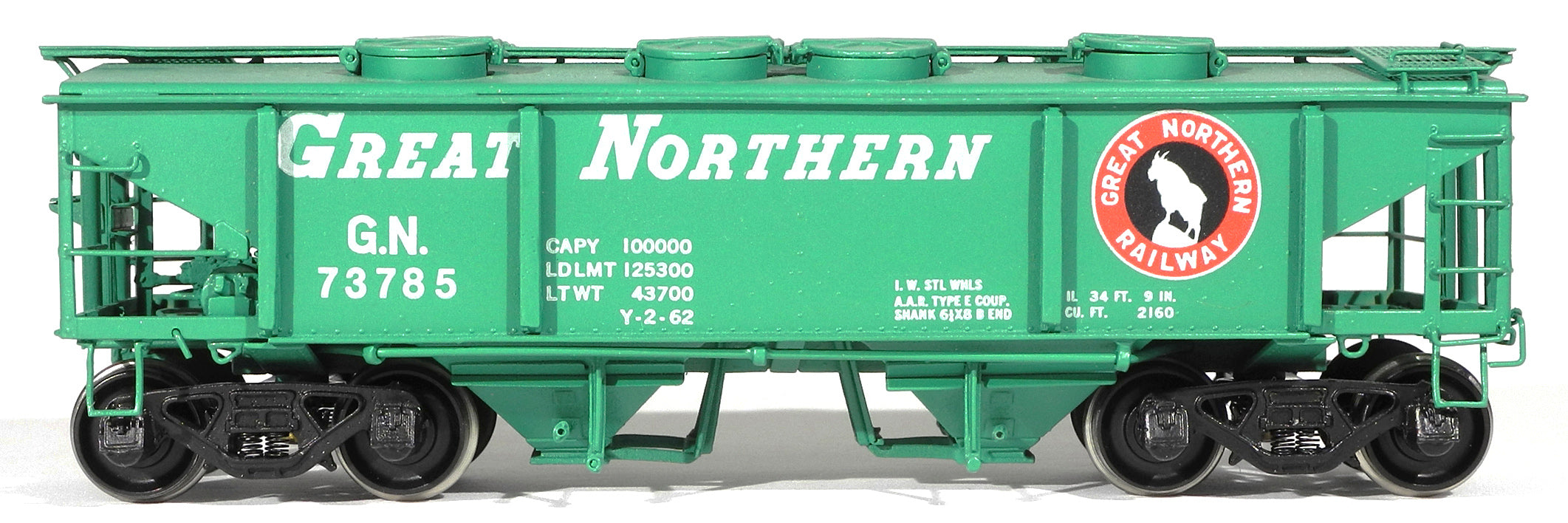

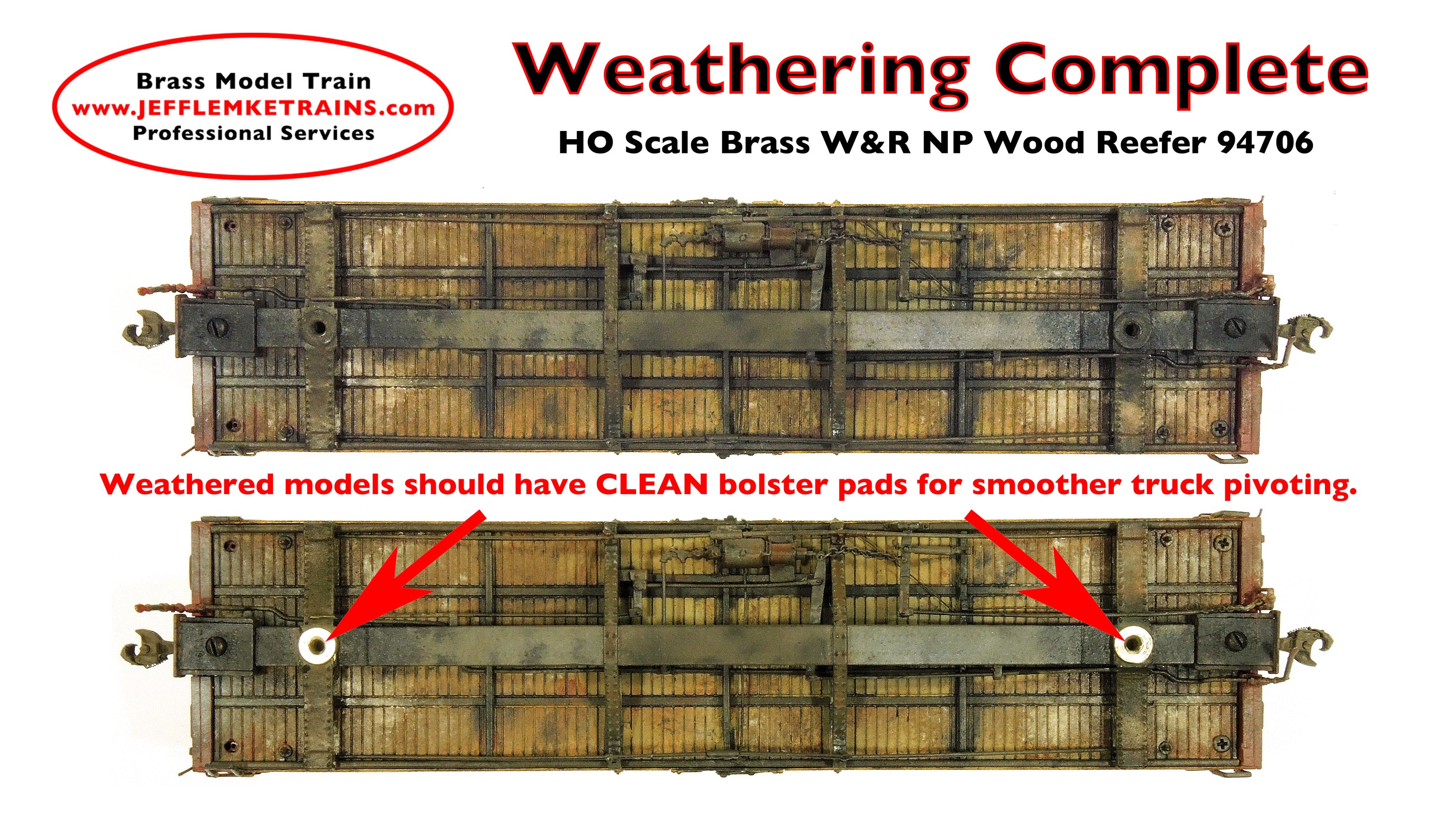

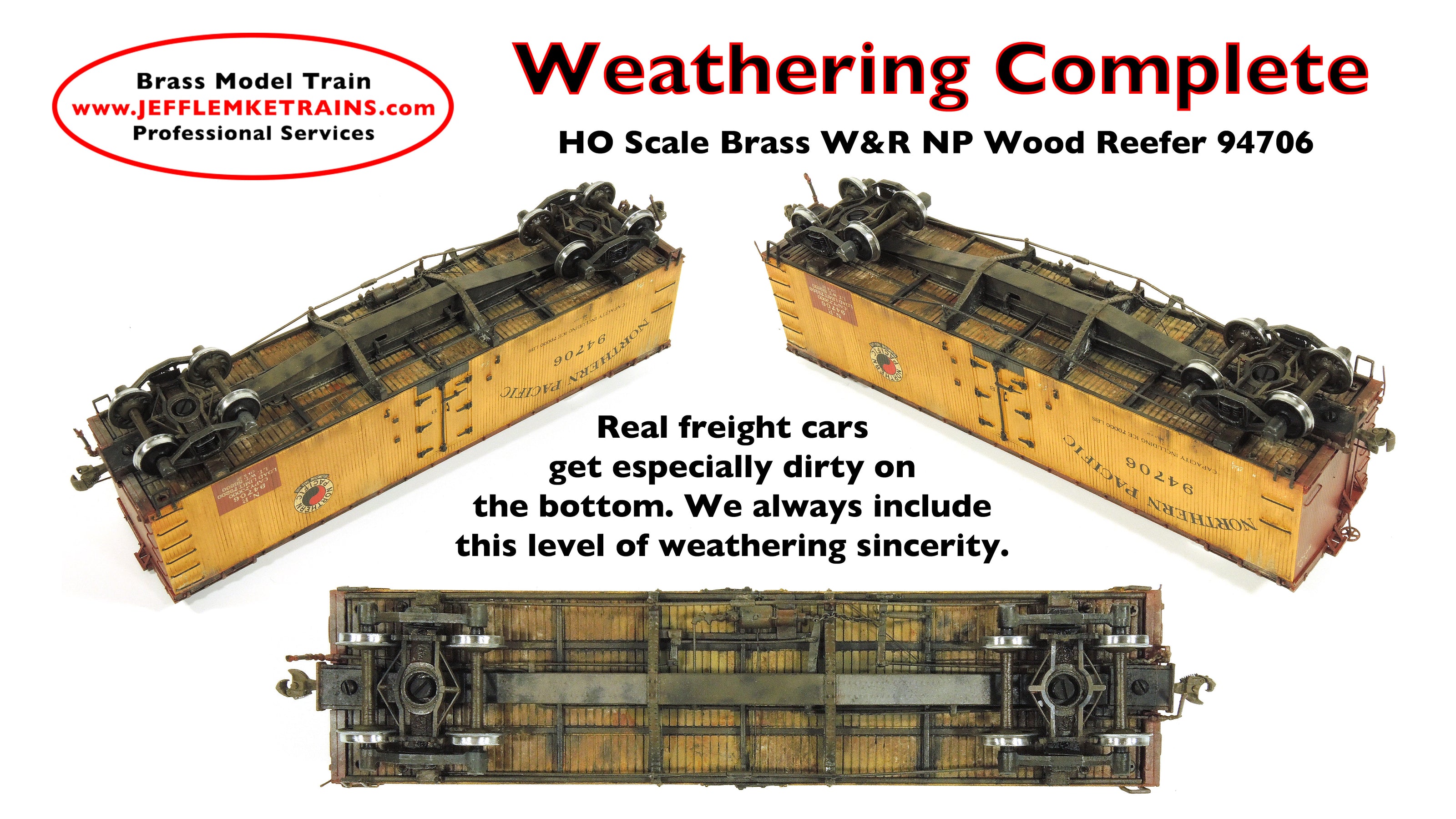

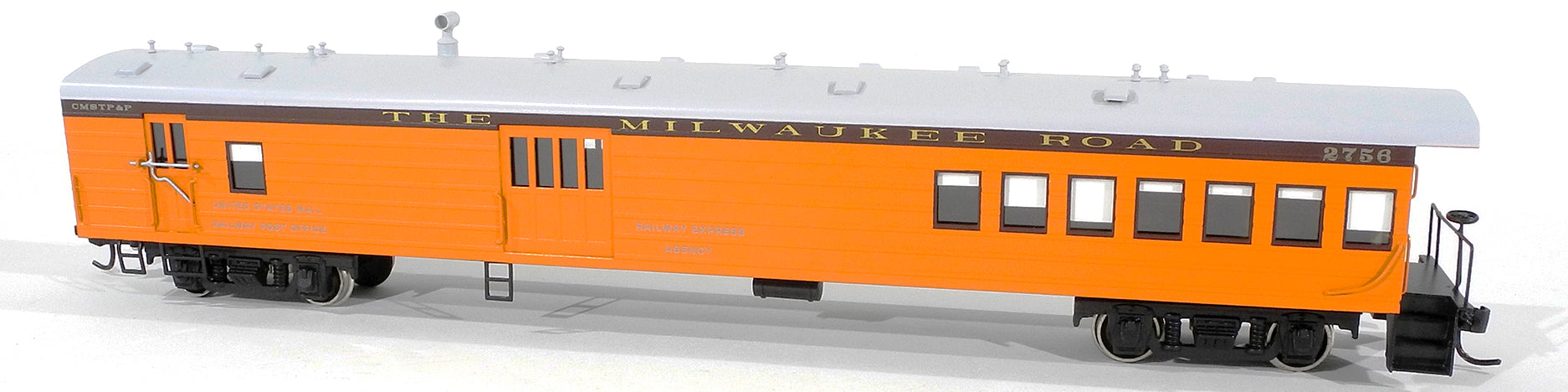

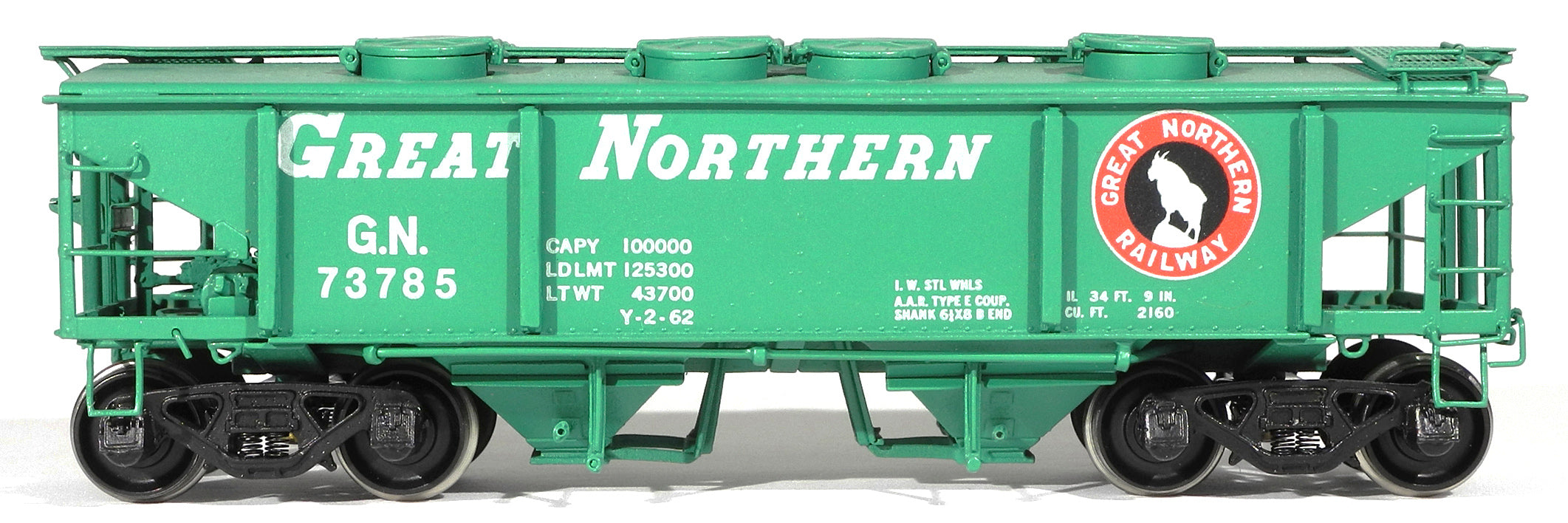

Realistic Weathering of Freight Car Models

-

See Larger Image

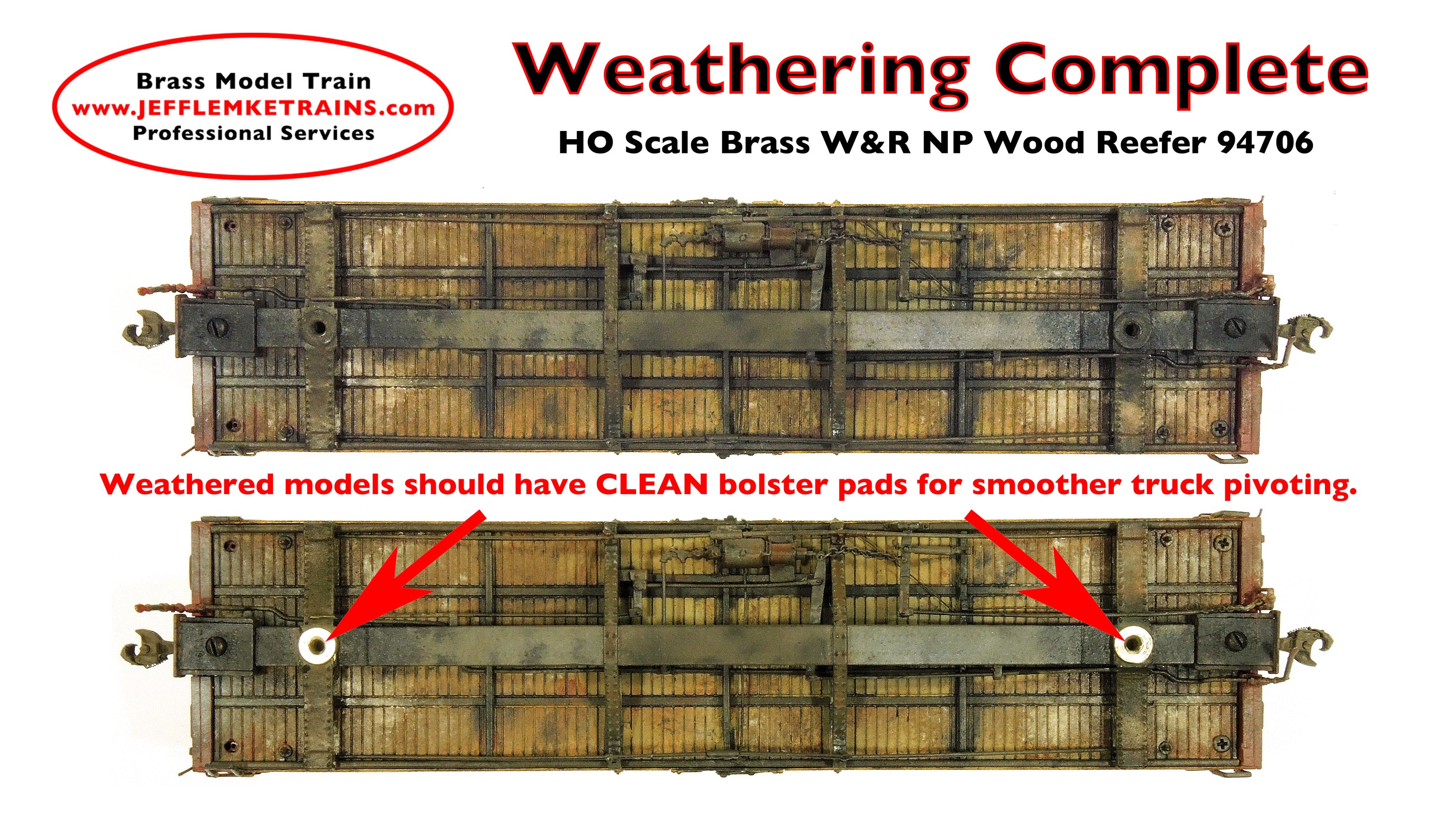

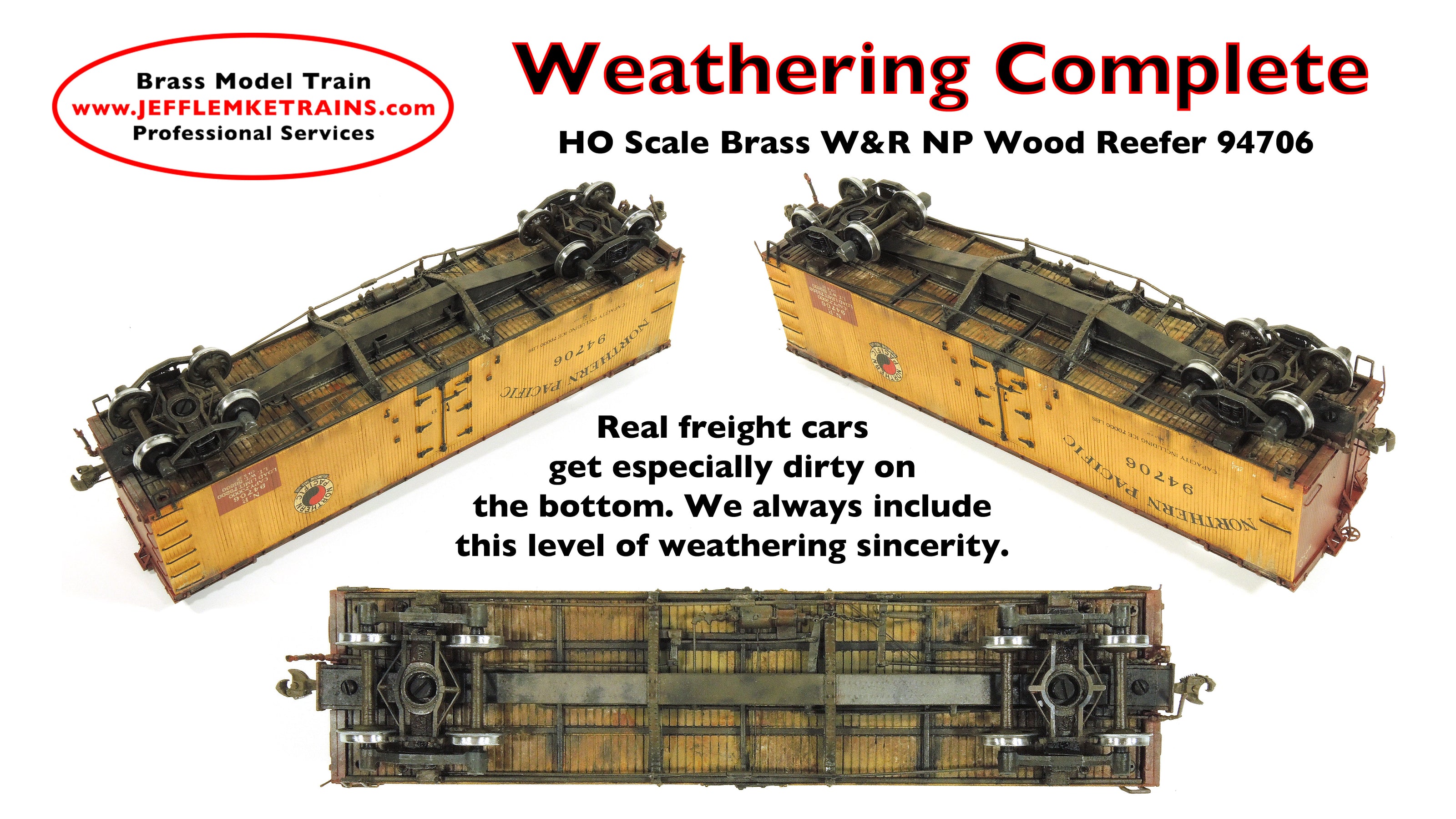

See Larger ImageFreight cars get very dirty in service. That dust and grime effects different areas of the car in different ways.

-

See Larger Image

See Larger ImageAny time that underframes get painted or weathered, it's important to keep clean the bolsters where trucks pivot.

-

See Larger Image

See Larger ImageOur weathering effects include the entire underframe too. Wheels treads should be prototypically bright to show use.

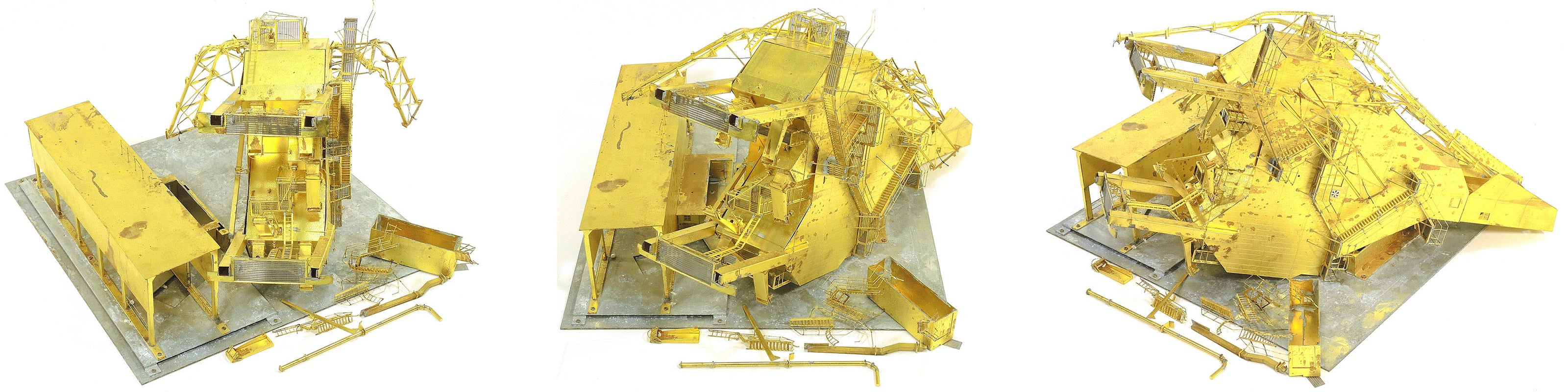

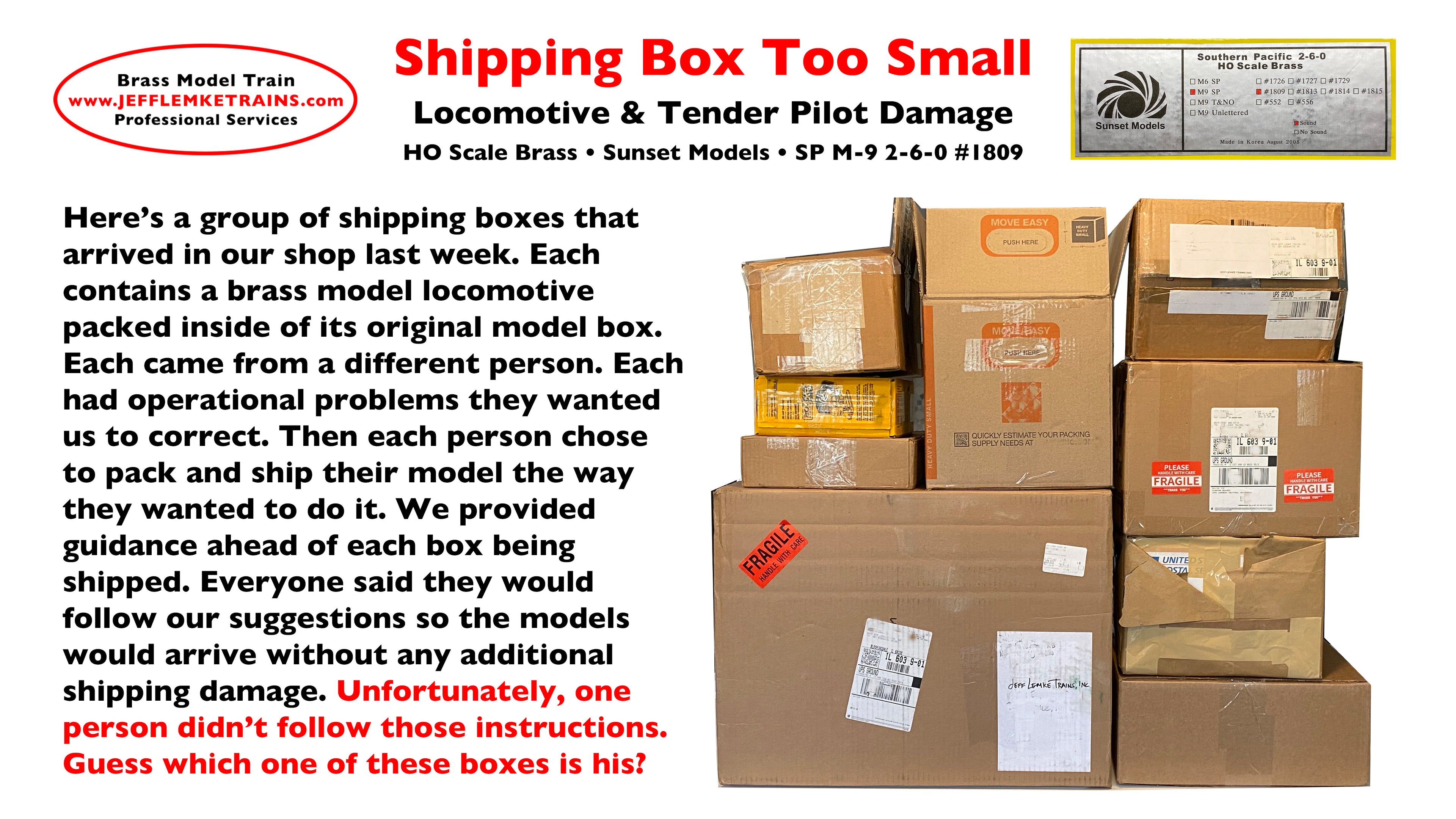

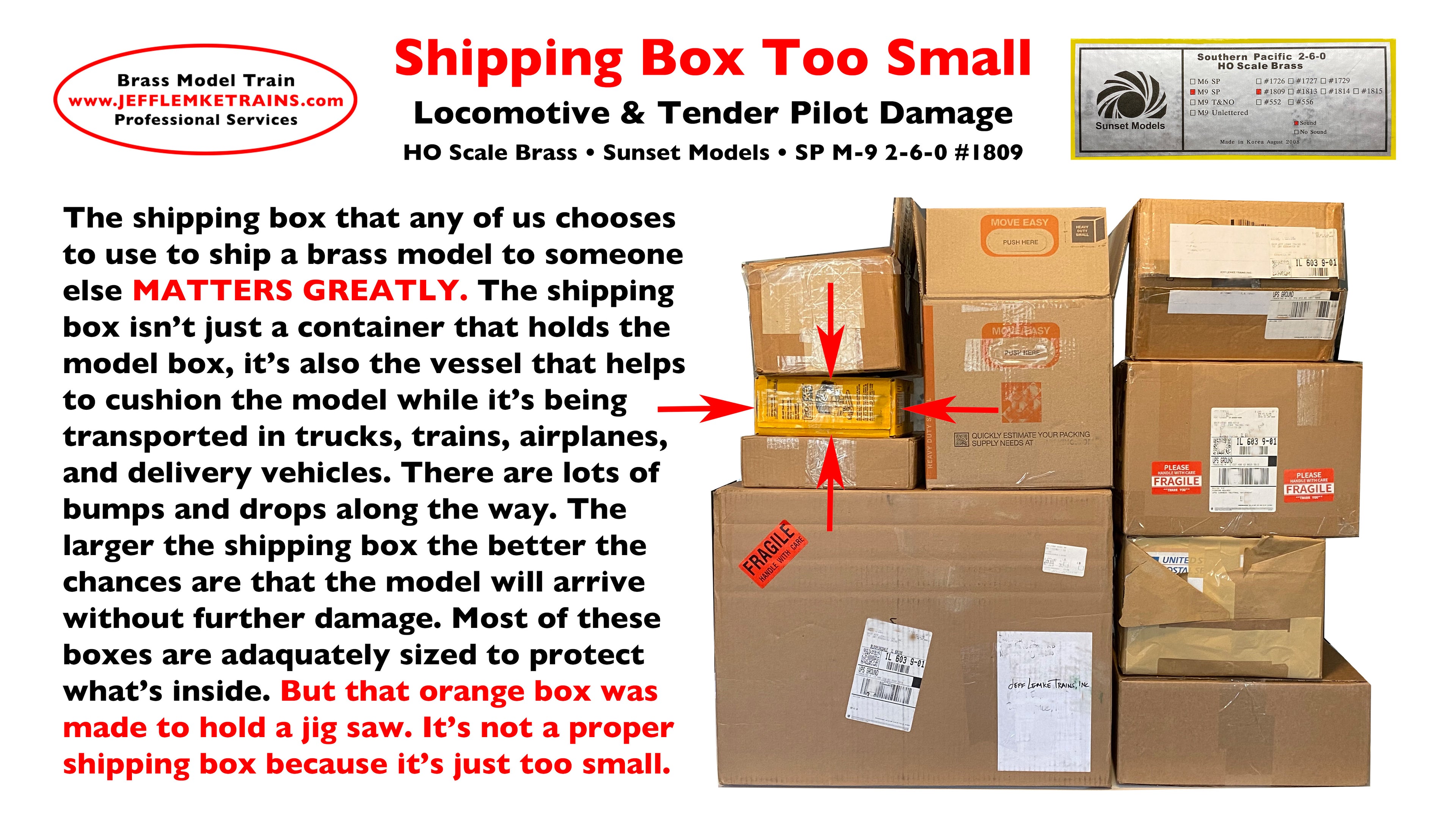

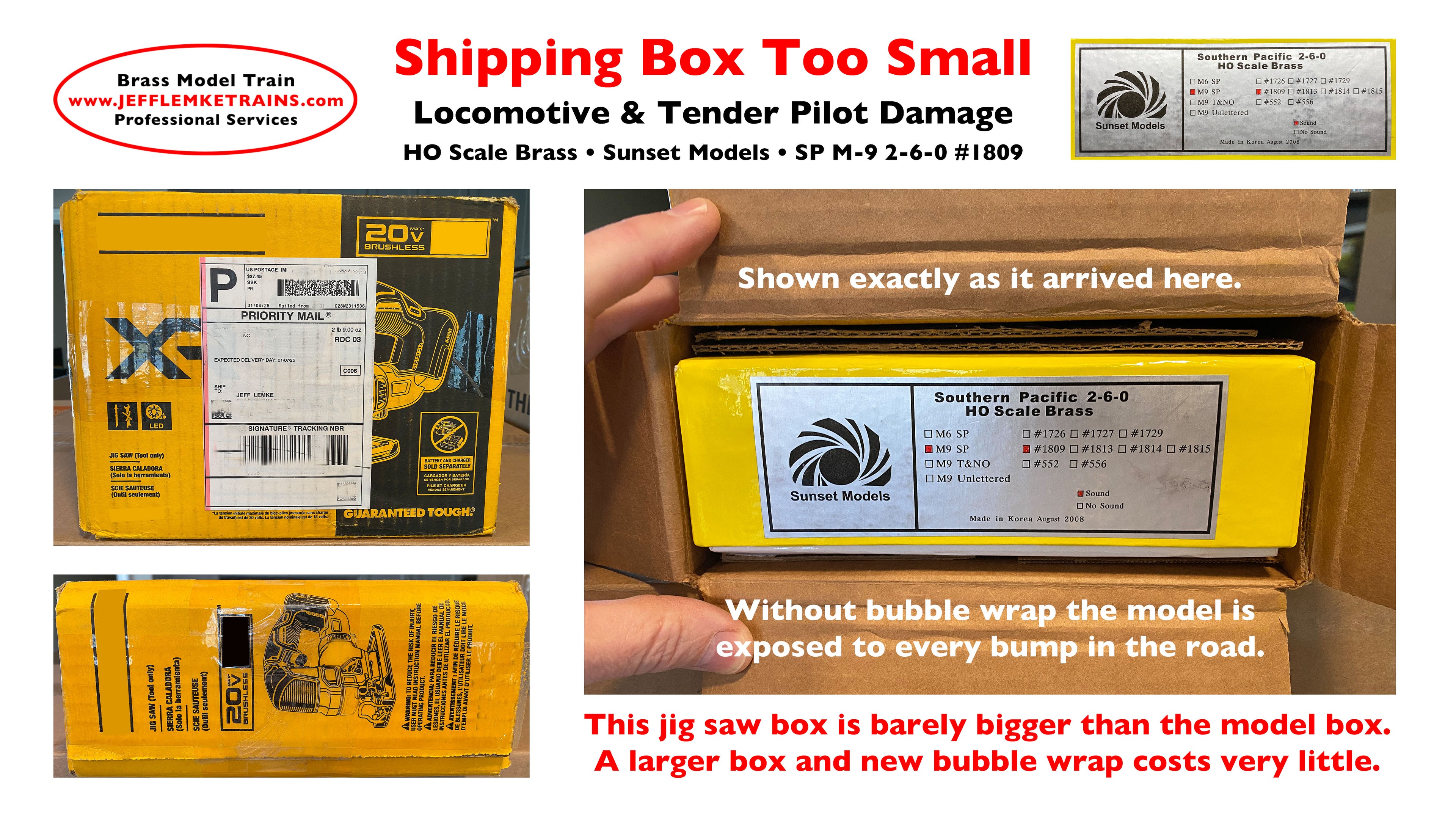

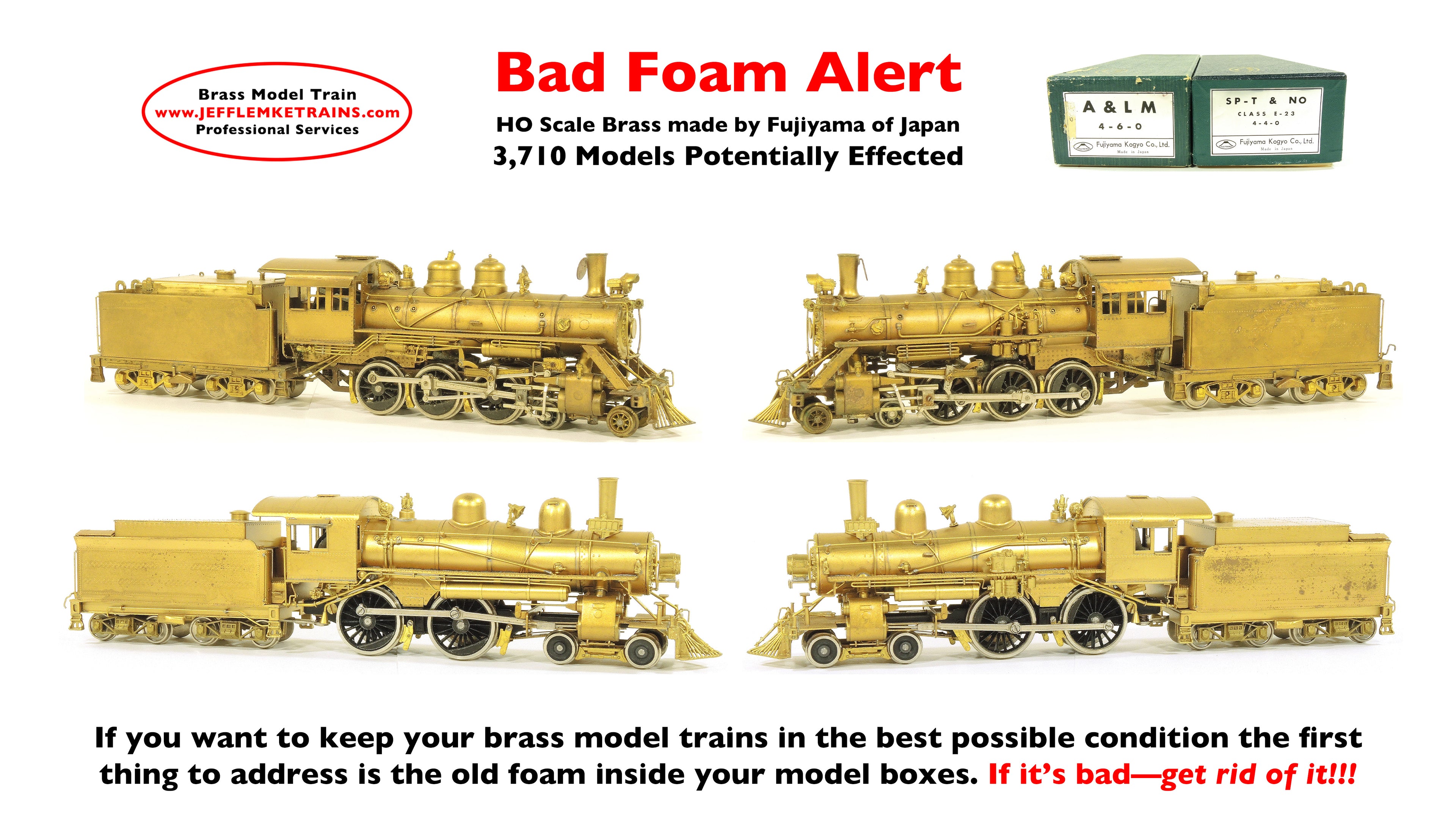

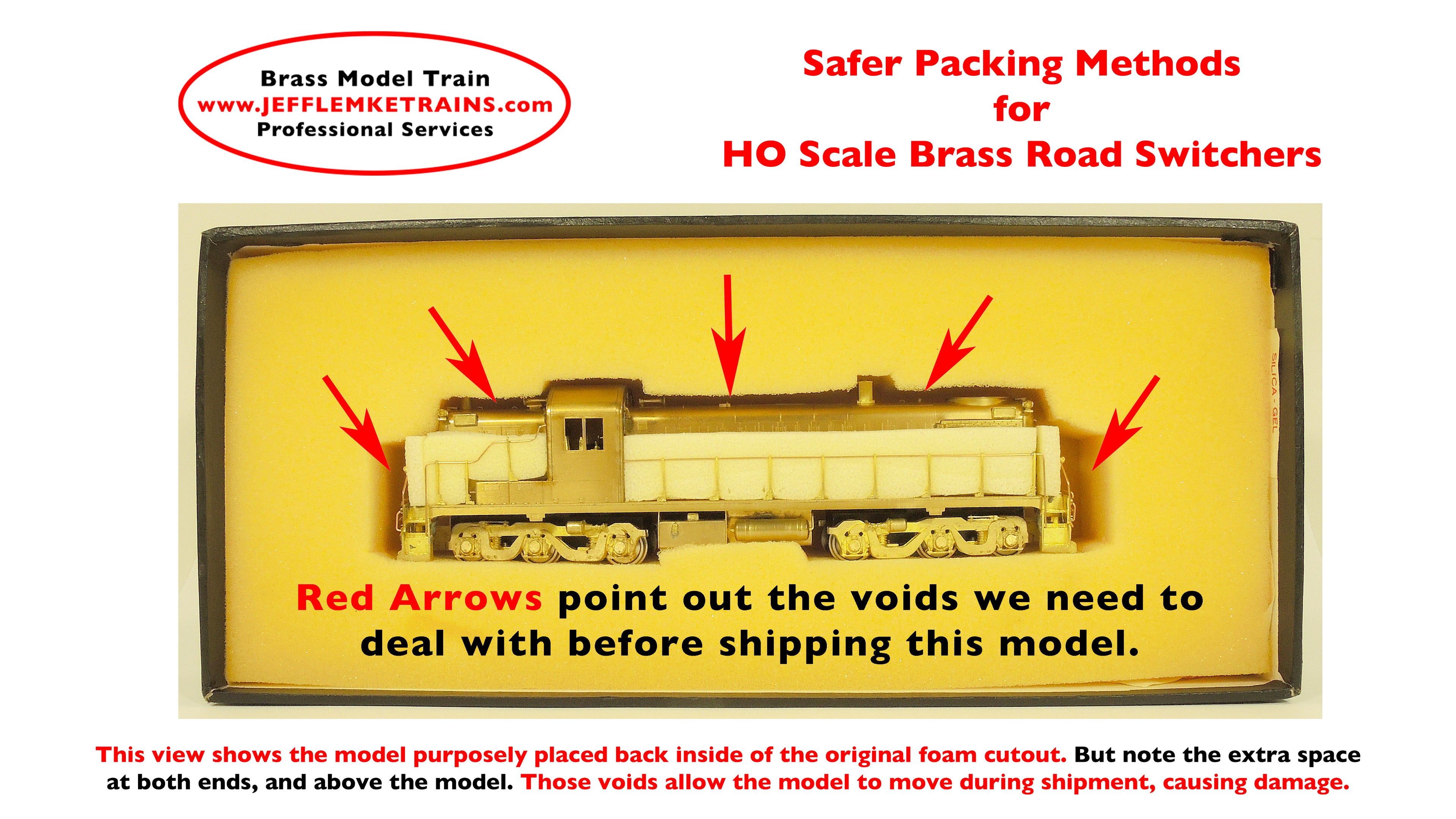

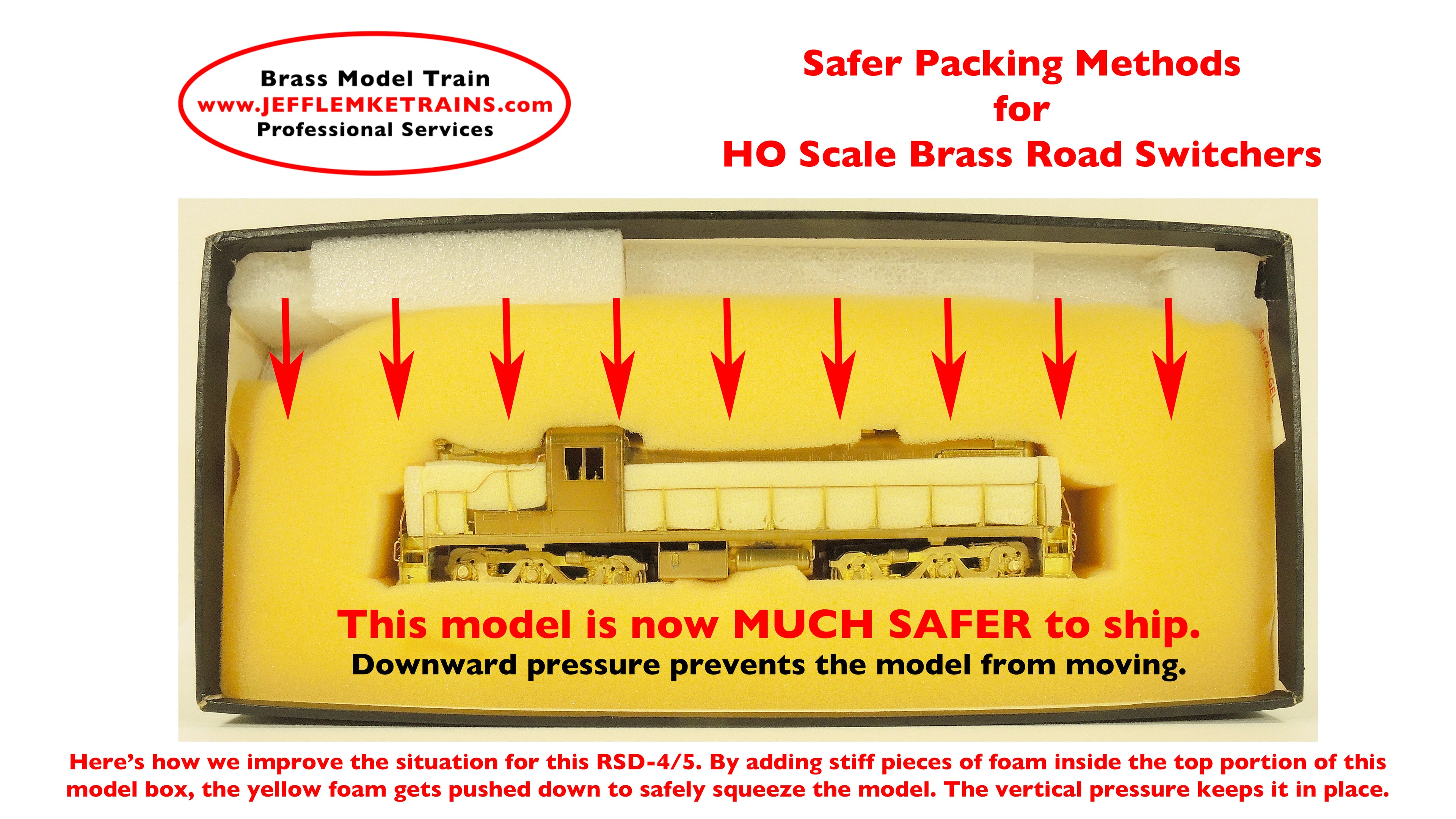

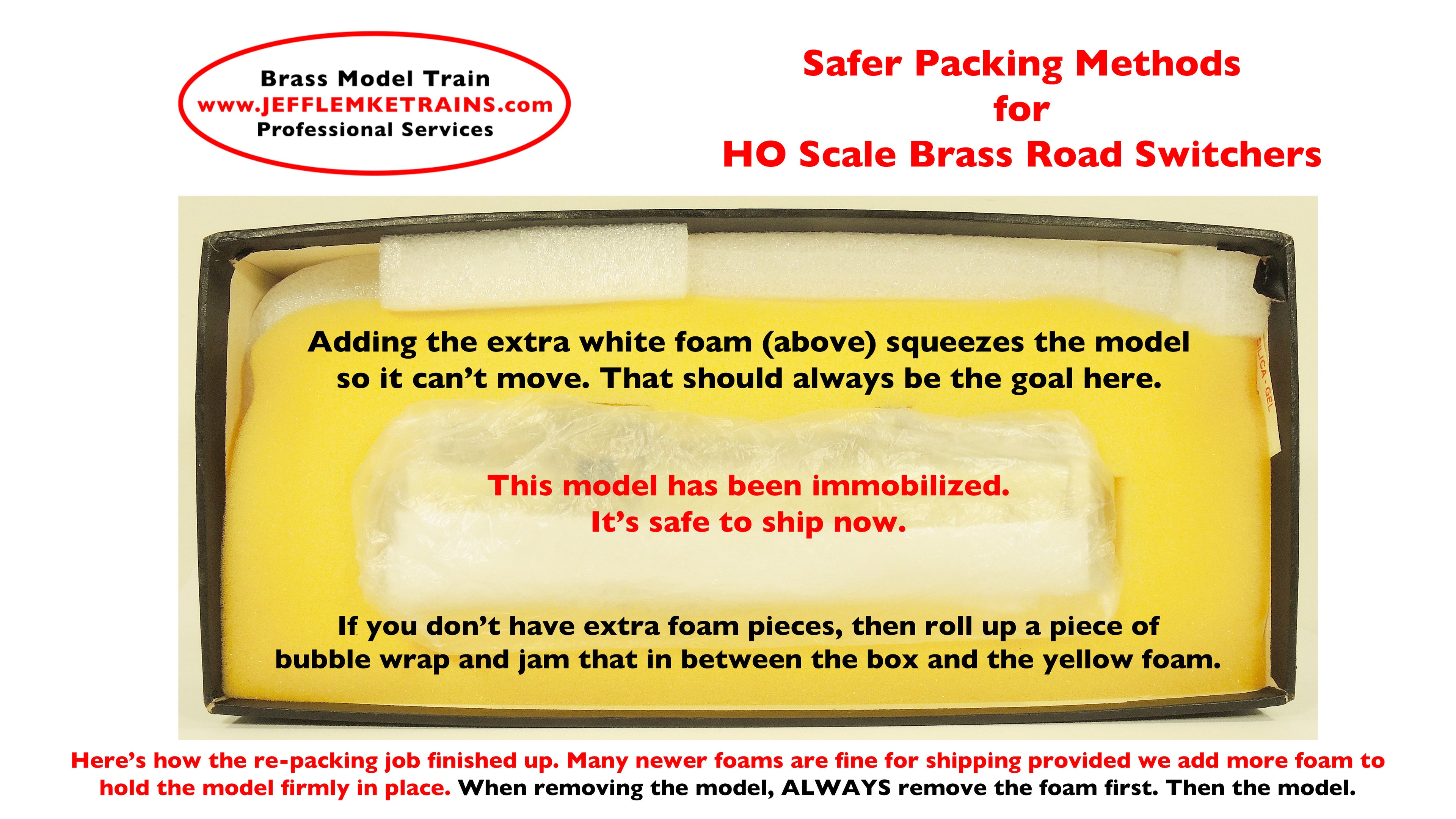

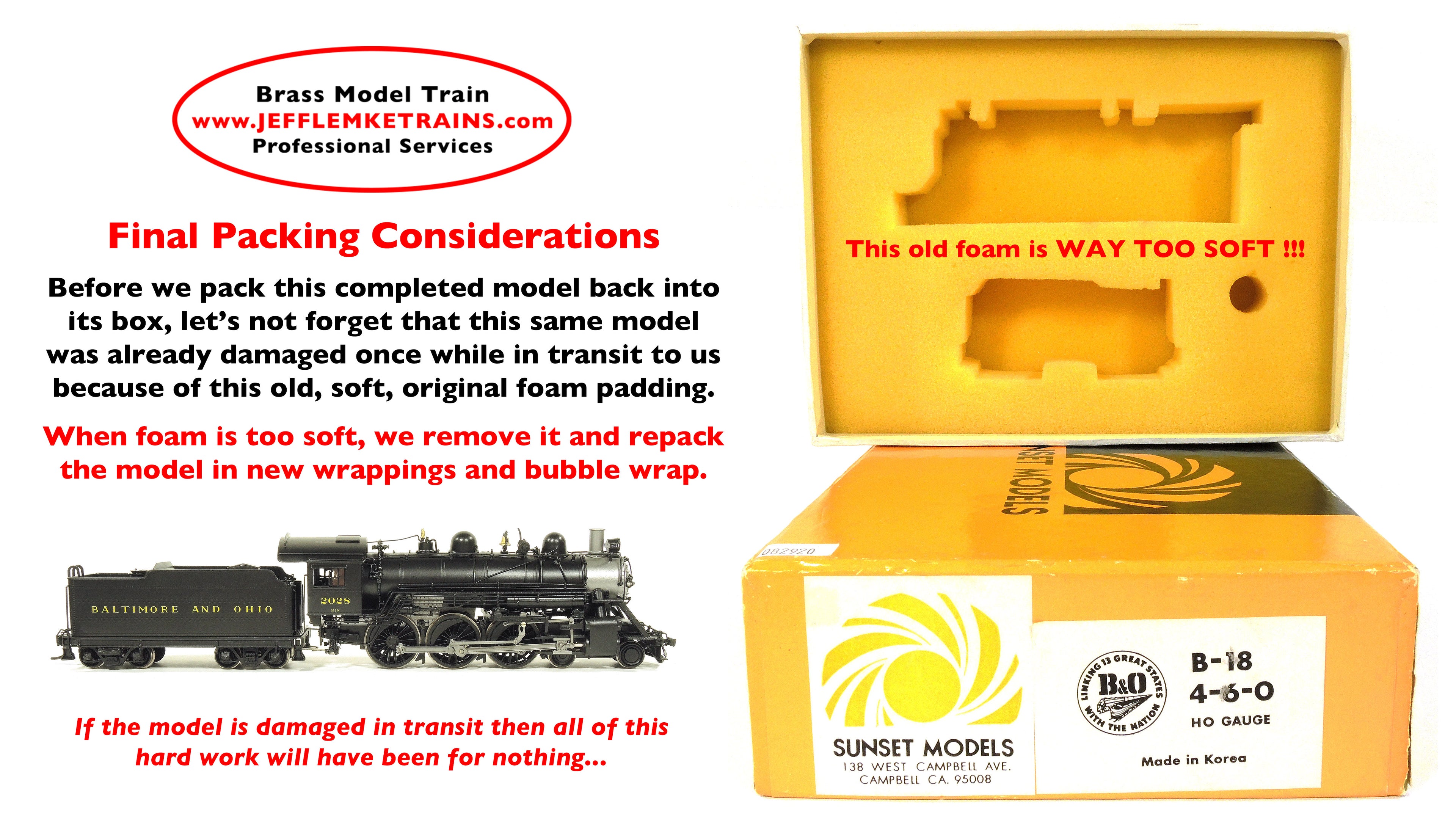

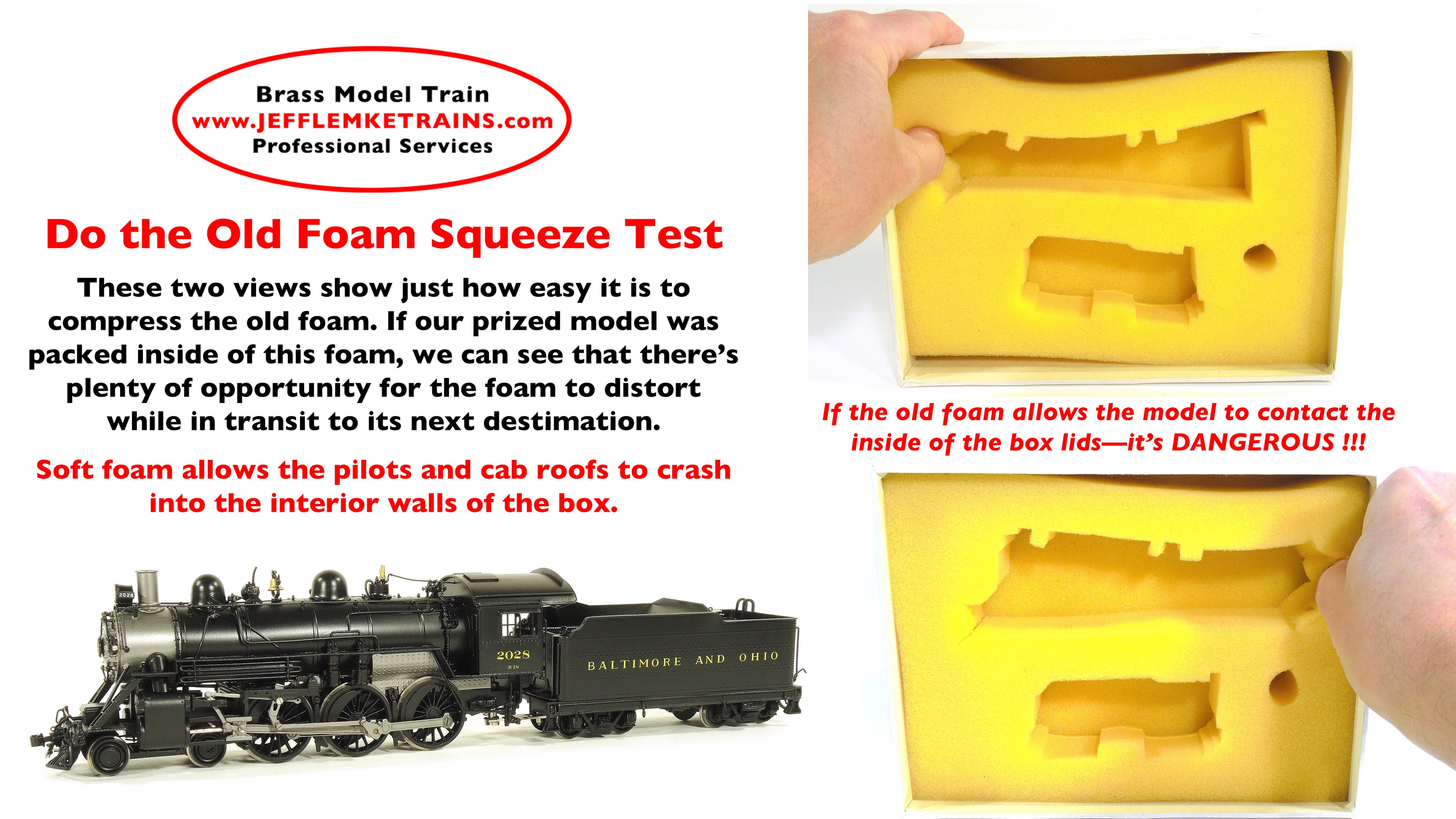

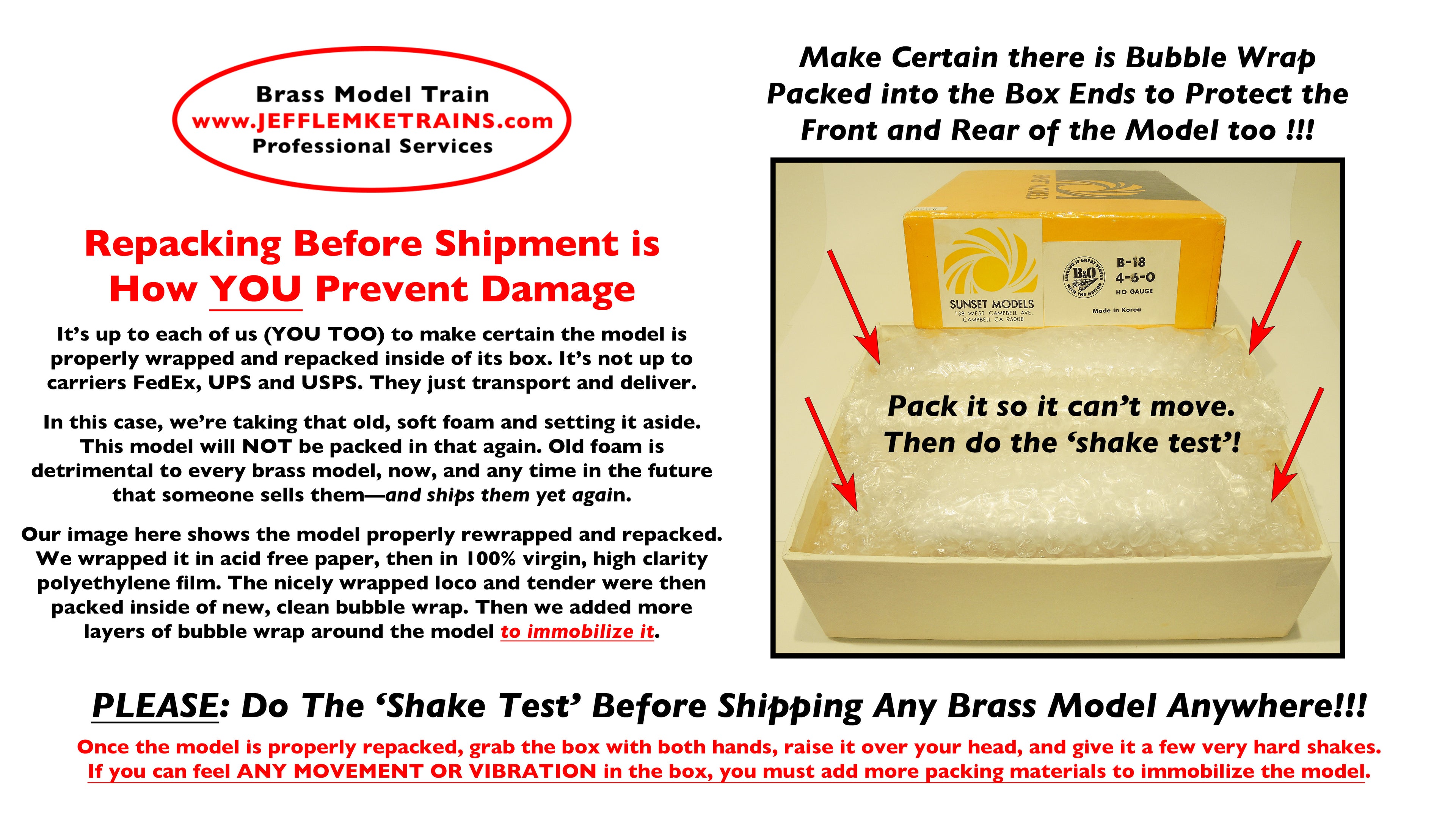

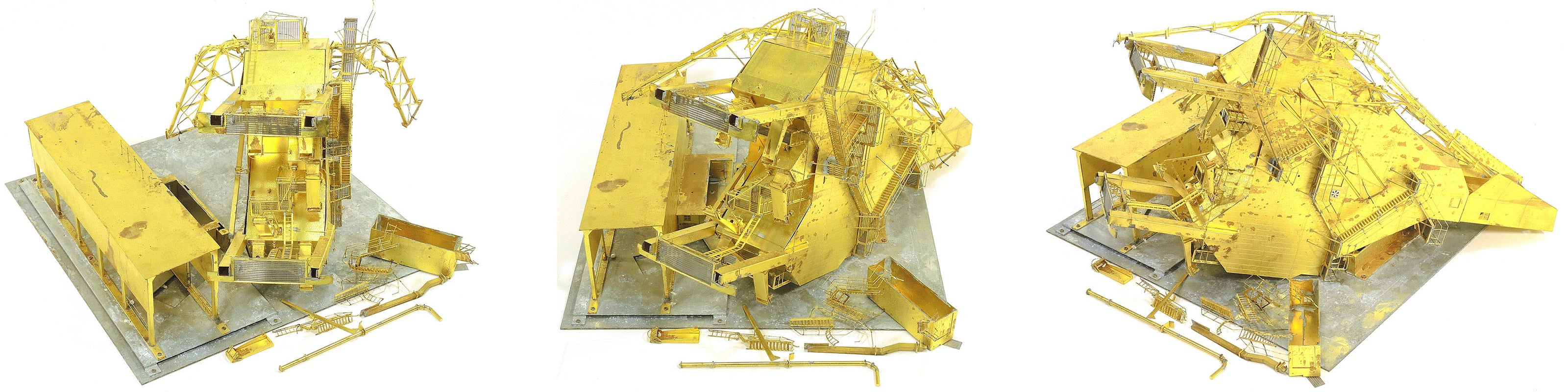

The Hazards of Shipping Brass Models

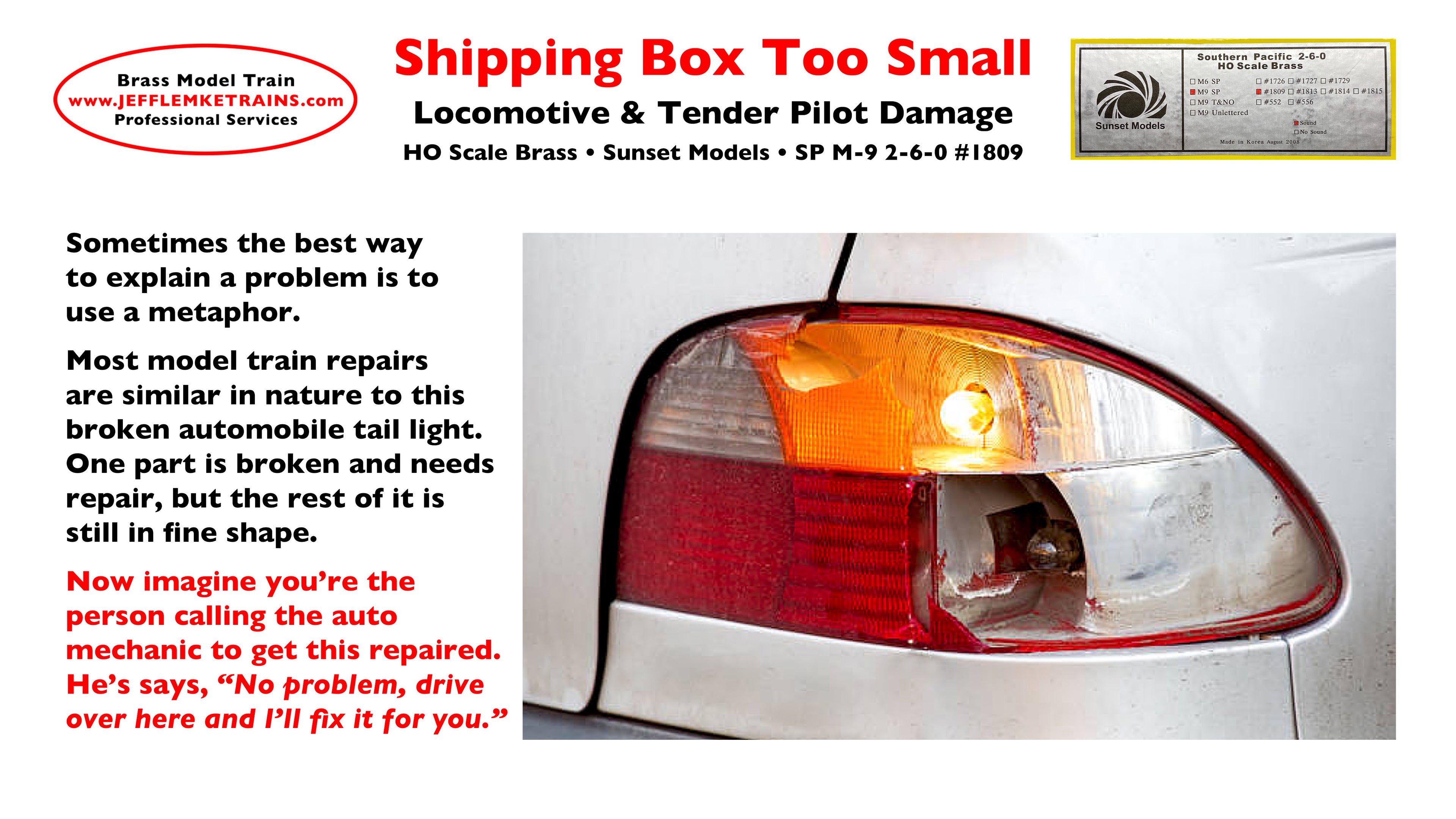

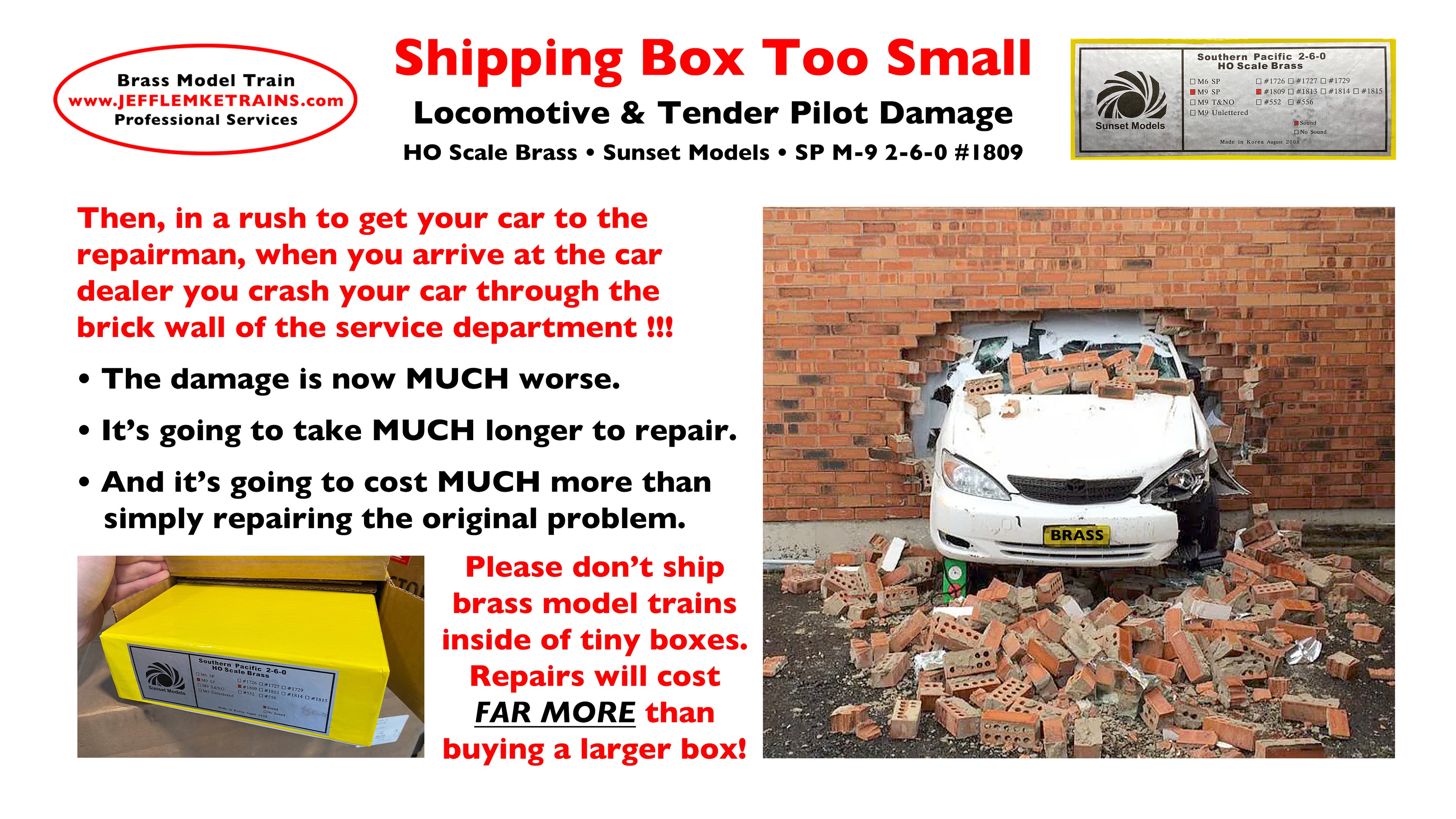

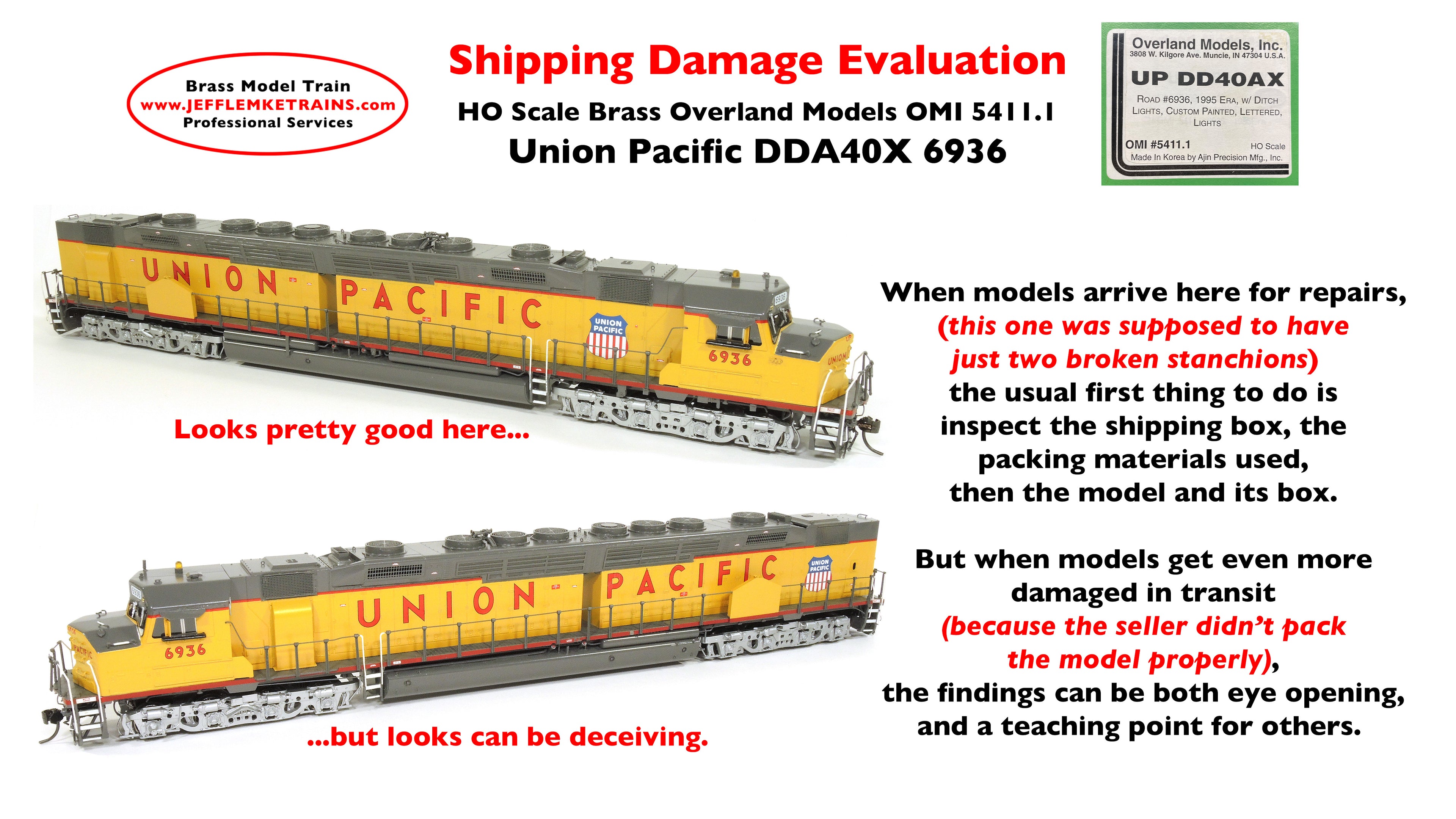

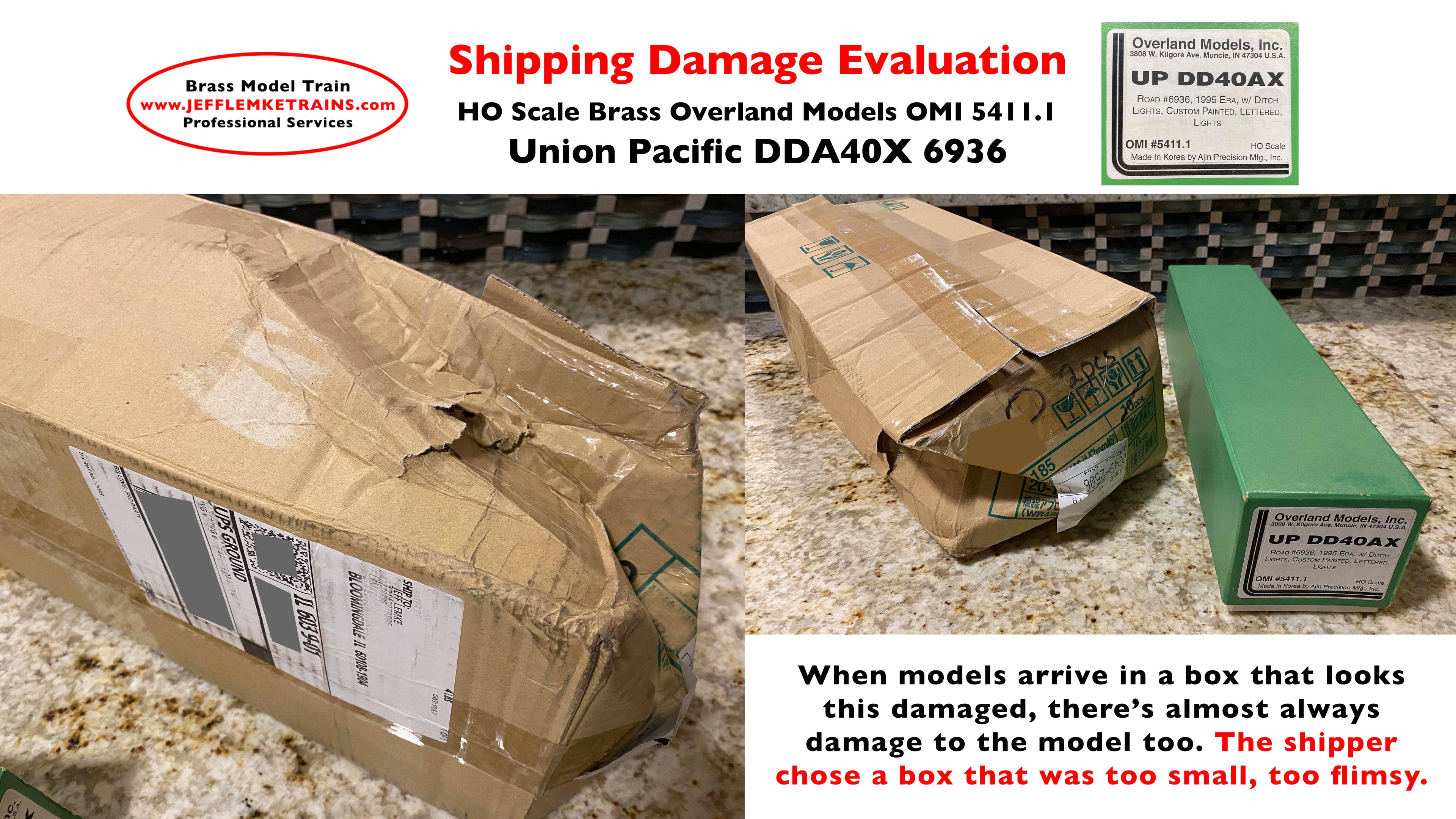

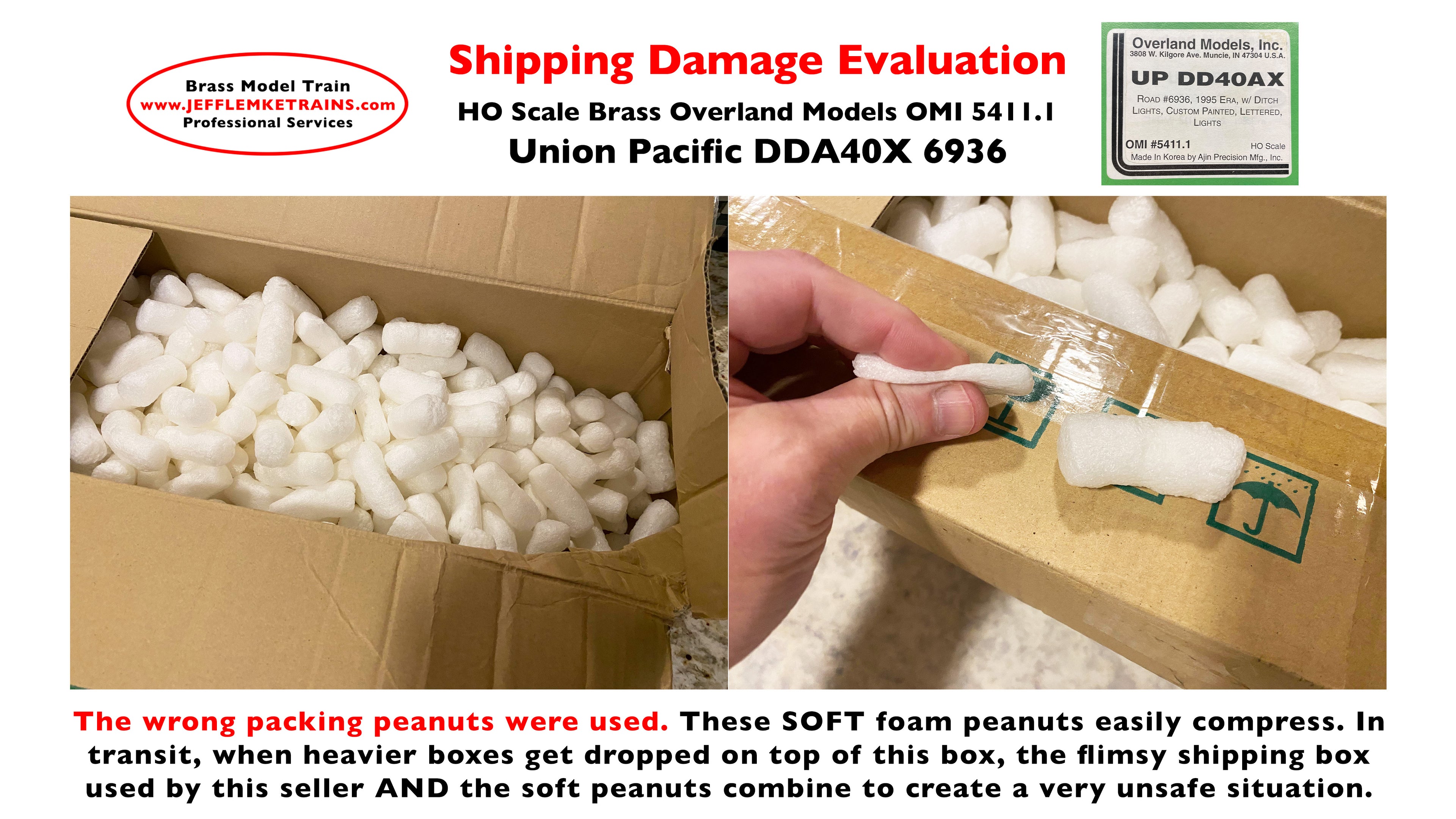

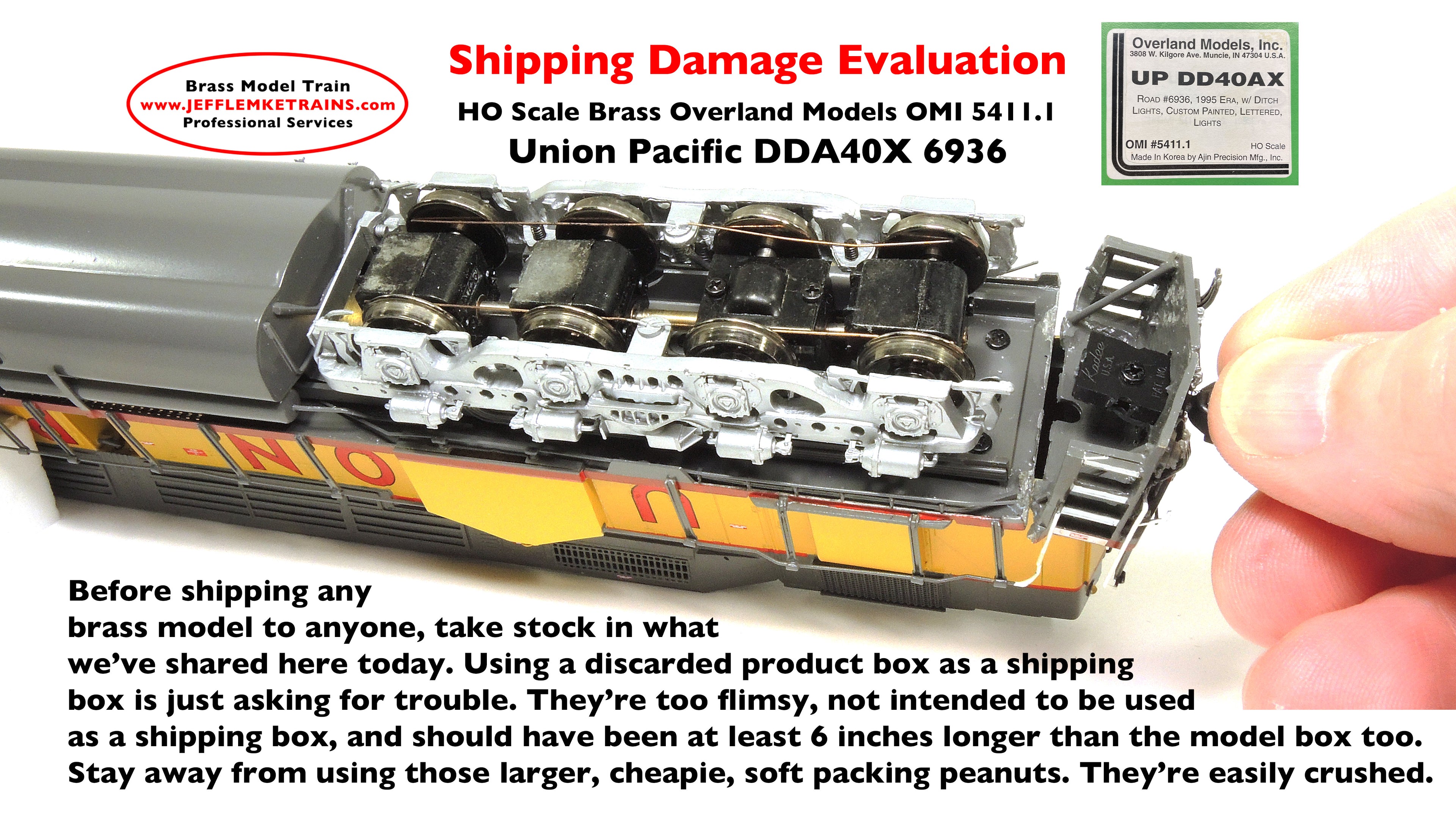

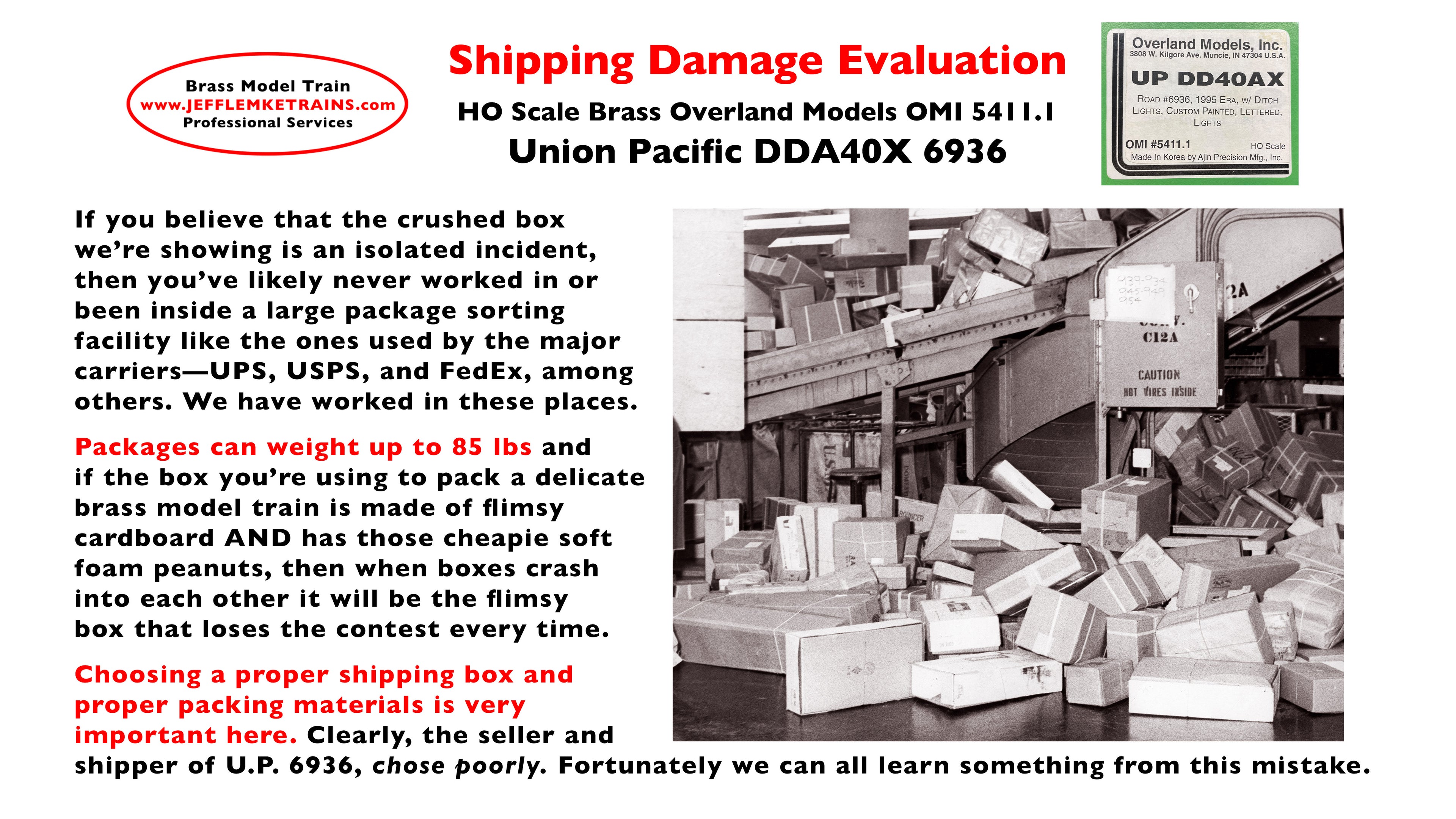

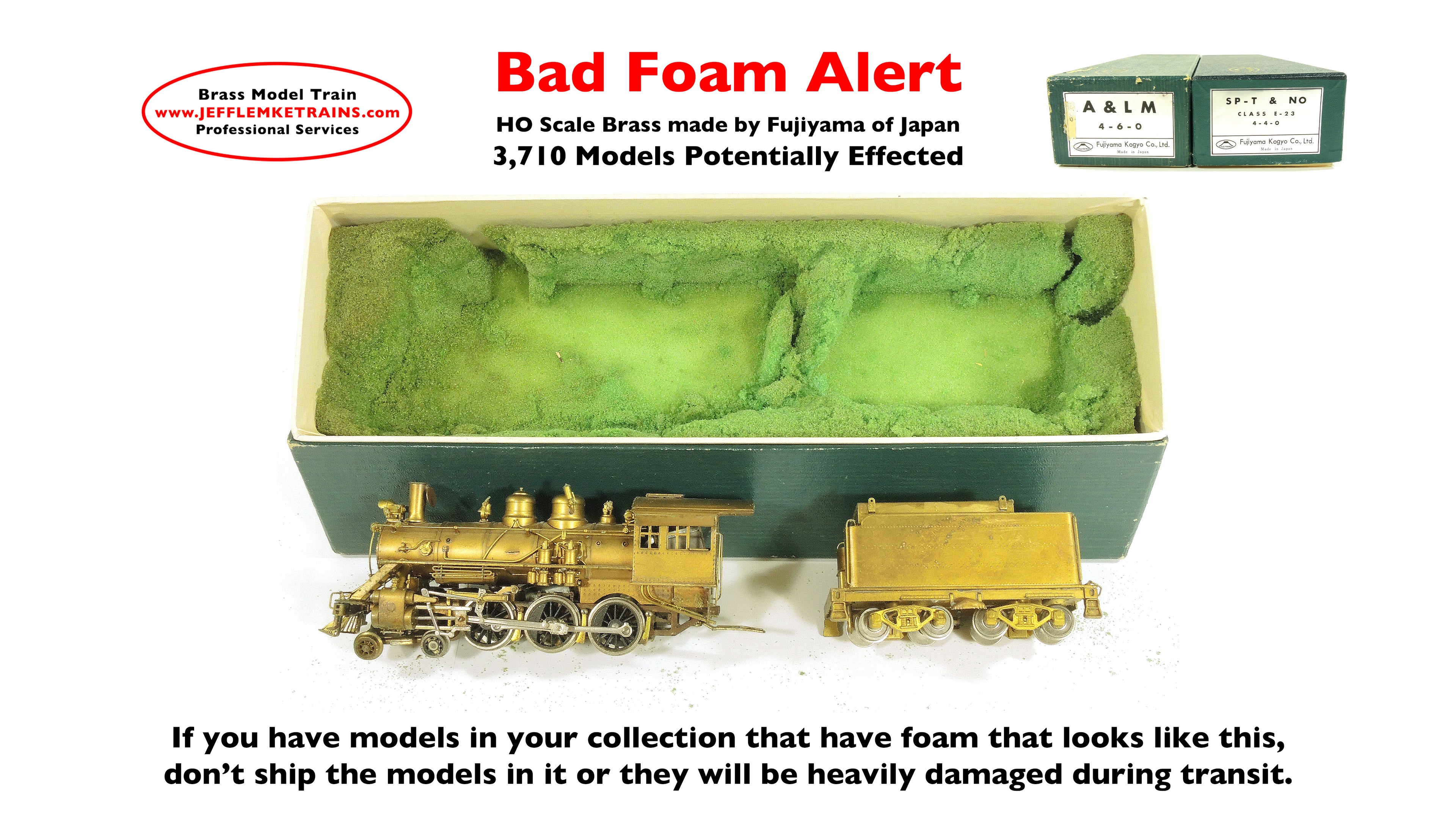

We're devoting this section of our website to help others understand that shipping brass models these days is potentially FAR MORE HAZARDOUS to the model than it ever was when the models were originally built, imported, and sent to dealers.

FACT: It's rarely a carrier's fault when brass models get damaged in transit. It's almost always the person who packed the box that caused the problem—even before handing the package to UPS, USPS or FedEx. Our Facebook page is filled with graphic examples of what NOT TO DO. Here, we're sharing several of the best examples from our vast scope of work in this regard.

Without proper guidance, every day, dozens of brass models get wrecked in transit. That's due to a lack of situational awareness on the shipper's part. So we've also included proper steps that anyone can take so their brass models arrive at their next destination in the exact same condition. It's all about safe landings and how to make that a reality for YOUR brass models.

Please share this information with anyone you buy from so they can safely ship the brass model you just bought from them!

Q and A: Brass Model Train Learning Center

-

Your TECH SUPPORT and CONSULTING SERVICES look invaluable. Do you consult on selling a collection?

Learn more here -

Joint Project Video: Paint & Weathering by Jeff Lemke Trains, Inc. ESU LokSound DCC installs by ELS Train Service.

See and Hear Them Now -

Is it necessary for me to use paid TECH SUPPORT to begin a dialogue with you about my Brass Model Trains?

Learn more here -

What separates Professionally Painted Brass Model Trains from those that were simply Custom Painted?

Learn more here -

How can I repack my Brass Model Trains to arrive safely UNDAMAGED when I ship them through UPS and USPS?

Learn more here -

What does a Professional do to make certain the model runs flawlessly even after its been painted?

Learn more here -

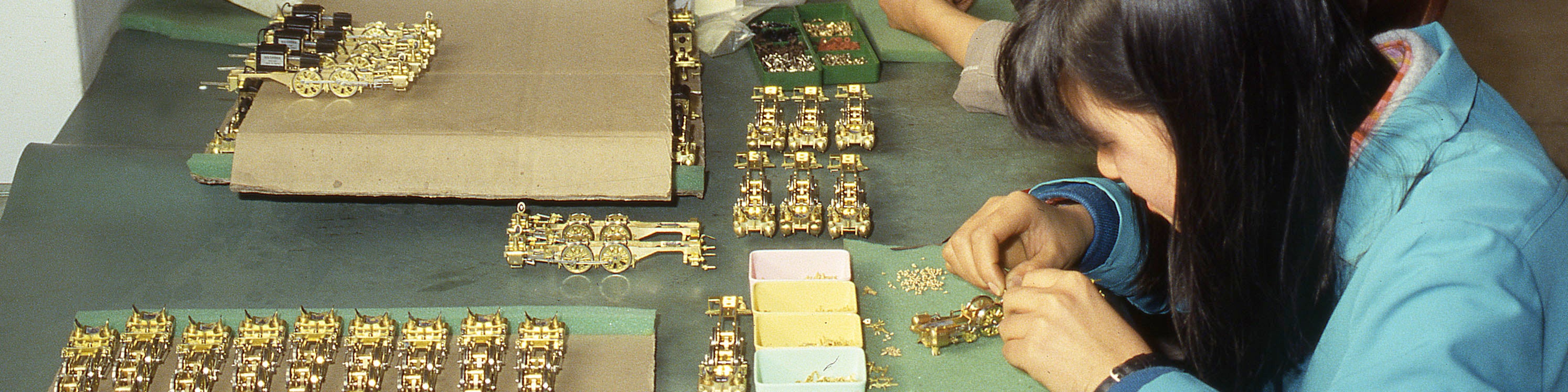

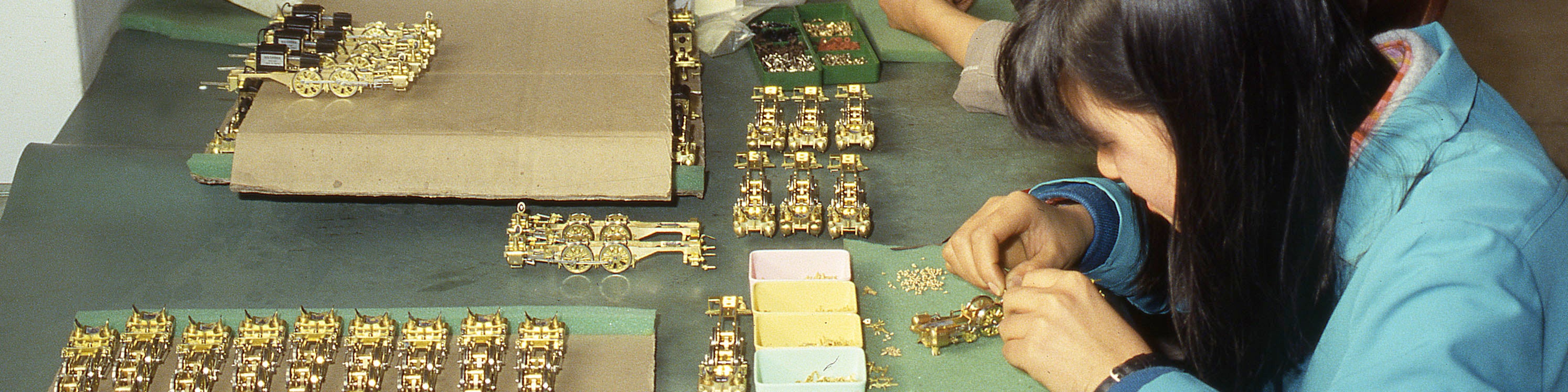

There's no substiture for experience when it comes to working on brass model trains. Ours came from Korea.

Learn more here -

With so many different Brass Model Train issues, I'm feeling "clear as mud" about how to begin. Can you provide help?

Learn more here -

What's the purpose of the factory clear coat and is necessary to remove it before painting a Brass Model Train?

Learn more here -

Ultra smooth smooth paint finishes comes from proper technique and having an ultra clean painting environment.

Learn more here -

I have factory painted freight cars I want weathered. Can you show us a few more examples of your weathering effects?

Learn more here -

A bunch of your Testimonials say the decals look painted on. Can you show a close up of what they're talking about?

Learn more here -

Positive outcomes are an important part of Professional Services. What kind of Safe-Shipping expertise do you employ?

Learn more here -

Are there certain types of brass model trains that I should be particularly careful about shipping?

Learn more here -

Before you ship models to us, take a good look at what needs to be repaired, and just send us those components.

Learn more here -

Some Brass Model Trains have terrible red dye stains all over them. Can you tell us more about this problem?

Learn more here -

Are there any safety issues with using ultrasonic cleaners and grit-blasting tools to clean my Brass Model Trains?

Learn more here -

Is it possible to repair a model badly damaged from a drop to the floor and how long does it take to repair?

Learn more here -

What's going on with some Brass Model Trains that I buy off auction sites? Many are damaged inside the box on arrival.

Learn more here -

Many of my beautiful factory painted diesels don't run on account of cracked drive train gears. Can you help with that?

Learn more here -

Are there models or repair jobs that are really tricky to work on? So much so that they challenge you as a professional?

Learn more here -

Are there "best" paints to use on moving parts like wheels, axles, and steam locomotive side rods?

Learn more here -

I have new old stock brass in perfect condition. Why is it that when I put it on the track it doesn't work at all?

Learn more here -

I have a variety of models needing repairs. What kinds of models do you regularly perform repairs on?

Learn more here -

I purchased a brass diesel model from another seller and it arrived with the end railings bent and broken. Now what?

Learn more here -

Do you have more pictures and stories to share from when you were working in the Brass Model Train factories in Korea?

Learn more here -

Did you know that Jeff Lemke Trains, Inc. has a large collection of color railroad slides and photographs for sale on eBay?

Learn more here -

Is it better to have clean models that look like new or weathered models that show the passage of time?

Learn more here -

How do you, or how did you, go about designing a new Brass Model Train from scratch? How long did it take?

Learn more here -

What are your thoughts on keeping history alive through our Brass Model Train collections?

Learn more here -

Can we see an example of a steam locomotive that you fully readied for DCC and painted with Tru-Color Paint?

Learn more here -

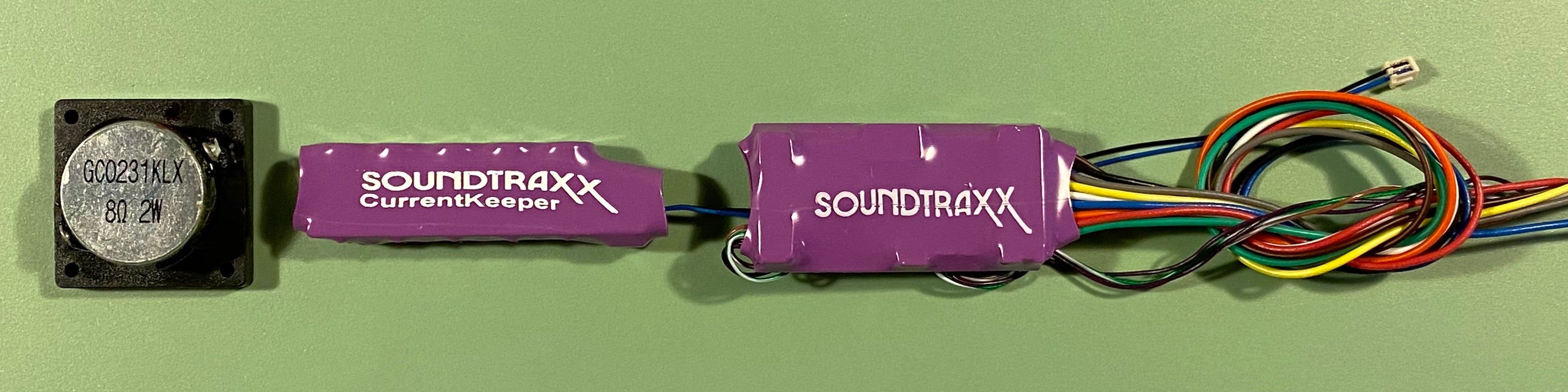

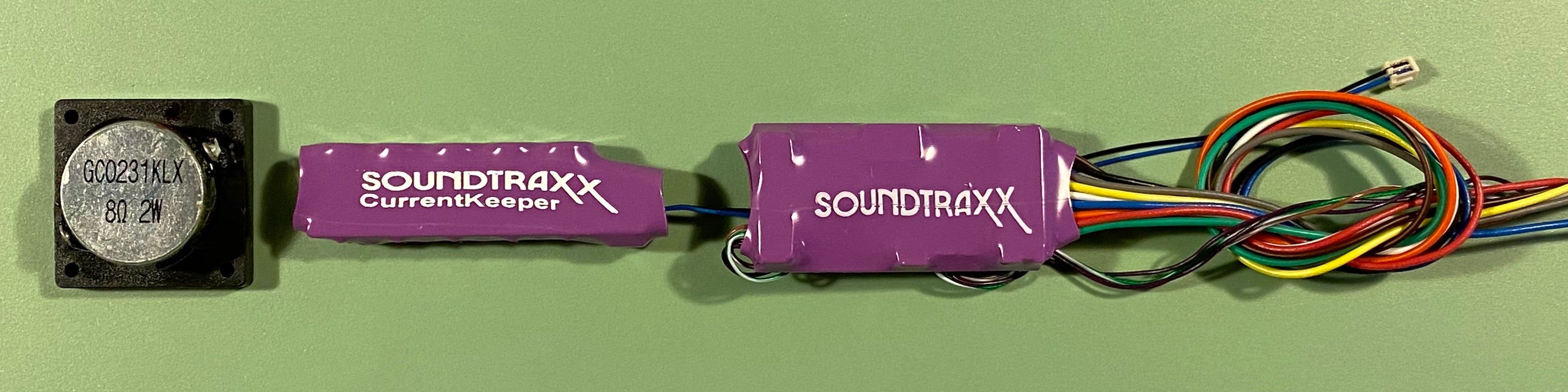

I have models that need DCC installed. Can you explain how you work with DCC installation partners?

Learn more here -

You seem to have a real knack for making basic black steam locomotives look like the real thing. What's the key?

Learn more here -

I just received a NJCB NH EF-2. It's covered with sticky foam. Can it be cleaned? How will it look afterwards?

Learn more here -

When should a model train collector seek a Professional's help to diagnose and repair a cherished brass model?

Learn more here -

My diesels don't run properly. Should I send the entire model or would it be safer to send just the drives?

Learn more here

Jeff's take on Brass Model Restorations for 2025 and Beyond...

Thank you for visiting my website today. Jeff Lemke Trains, Inc. is literally an army of one. Over the decades I've researched, designed, repaired, restored, rescued, painted and weathered more than 10,000 brass models. Today we work exclusively in HO, S and O scales for people around the world, including the best hobby shops from coast to coast, most of the brass importers that ever were, presidents of many of USA's Class 1 Railroads, and locomotive builders EMD and GE.

While working as the resident Research Specialist for Overland Models (during the high point of brass model production in Korea) I was invited to teach professional painting to the production managers at Ajin Precision in Seoul, South Korea. My first student was Mr. Se Ho Jang, who created his own brass model factory, BOO-RIM Precision Co., Inc. CLICK HERE to visit my Flickr site to see and read how brass models were made in Korea during the 1980s and 1990s.

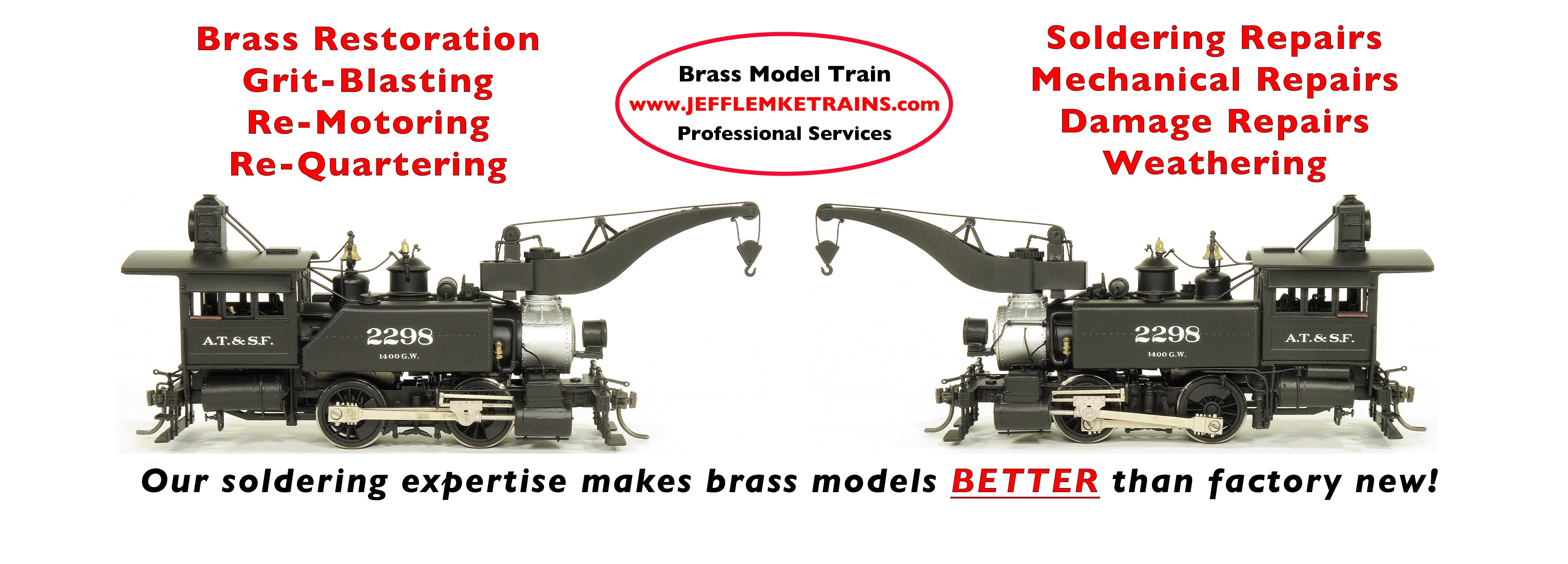

Thanks to the workers at Ajin whom I worked with side by side, I learned how to solder in the factories that made the models, while I taught them how to paint brass models. Today, I use a variety of traditional soldering sticks and stations, resistance soldering units ranging from 100 WATTS to 1,100 WATTS, and a micro-torch to perform my craft. My soldering acumen is expert level. That's precisely what's required to make pro-level repairs to finely crafted brass models.

Our soldering expertise make brass models BETTER than factory new.

Making soldering repairs to fully assembled models is FAR more difficult than anything factory workers encountered when making the models in the first place. But thanks to seeing how they were made, it's relatively simple for me now to make decisions on what can and can't be repaired. If you have a damaged or inoperative brass model train in HO, S or O scale, let’s put our heads together to come up with a solution. To get a project started, all that I need to see are a few photos of your model and a description of the problems you’re experiencing. They can’t all be brought back, but many of them can with the right tools, techniques, and expertise.

IMPORTANT—The painting side of my business was RETIRED in January 2024 so that I could focus exclusively on brass model train repairs, grit-blasting and chemical cleaning, touching up factory painted models, doing full restorations on unpainted bare brass models, and proto-realistic weathering too. If you’re in need of repairs or restoration AND a paint job too, I perform expert repairs, then utilize a vetted, full-time professional paint shop to get colors on the model.

Likewise, DCC installers tend to be in the highest demand these days with so many collectors requesting DCC installs in their locomotives. While I do set up brass models to properly accept DCC components (without bending or breaking any parts and without ruining the factory paint jobs), I've always outsourced the component installations to several very capable electronics wizards known to me locally. Like me, they operate full-time professional businesses as well. Specialization really does make for the finest outputs across the repair, painting, weathering and DCC installation disciplines. Utilizing trusted industry colleagues who have similar values and performance standards means every service we perform is reliably well-done.

MORE IMPORTANT—As with any art that is in high demand, it's important to understand that the lines can be quite long for the kinds of services we provide. Not just here, but with ANY service provider. We typically maintain a work load of roughly 75 projects. Our facility is essentially a brass model triage center. Some models come and qo quite quickly, in just a week or two, to a few months. Models requiring more complicated repairs can be here for 3-6 months. Serious repair or rebuilding work (dropped models or those with severe shipping damage) can easily be here a year or more. As each model is unique, so too are the repairs required to bring it back to full functionality. Like the railroad itself, everything in the brass model repair business is linear. Meaning, that when jobs ahead of yours go slow, everything in line behind that work gets delayed as well. That said, it's rarely possible to provide hard turn-around estimates since there are too many unknowns hiding inside of every job that arrives here. If you're a patient person, then we're happy to work with you to provide the finest brass models repairs and restorations.

It's been said that the three most important variables in this line of highly skilled work are:

1) Price; 2) Turn-around; 3) Quality of work performed.

Our hourly rate since 2017 is still just $39/HR, + parts + materials + shipping.

Turn-around is ALWAYS based on a combination of every job that's already here ahead of yours, along with the condition of your model when it arrives here.

We're known for the QUALITY OF WORK we consistently provide to our clients.

If the lowest price and fastest turn-around are your most important considerations, then frankly, we will not have a fit. But if the highest quality repairs and restorations are omni-important to you, then you've come to the right place and you're going to love what we create for you.

Thanks again for visiting our website today. We do appreciate YOU.

Cheers!

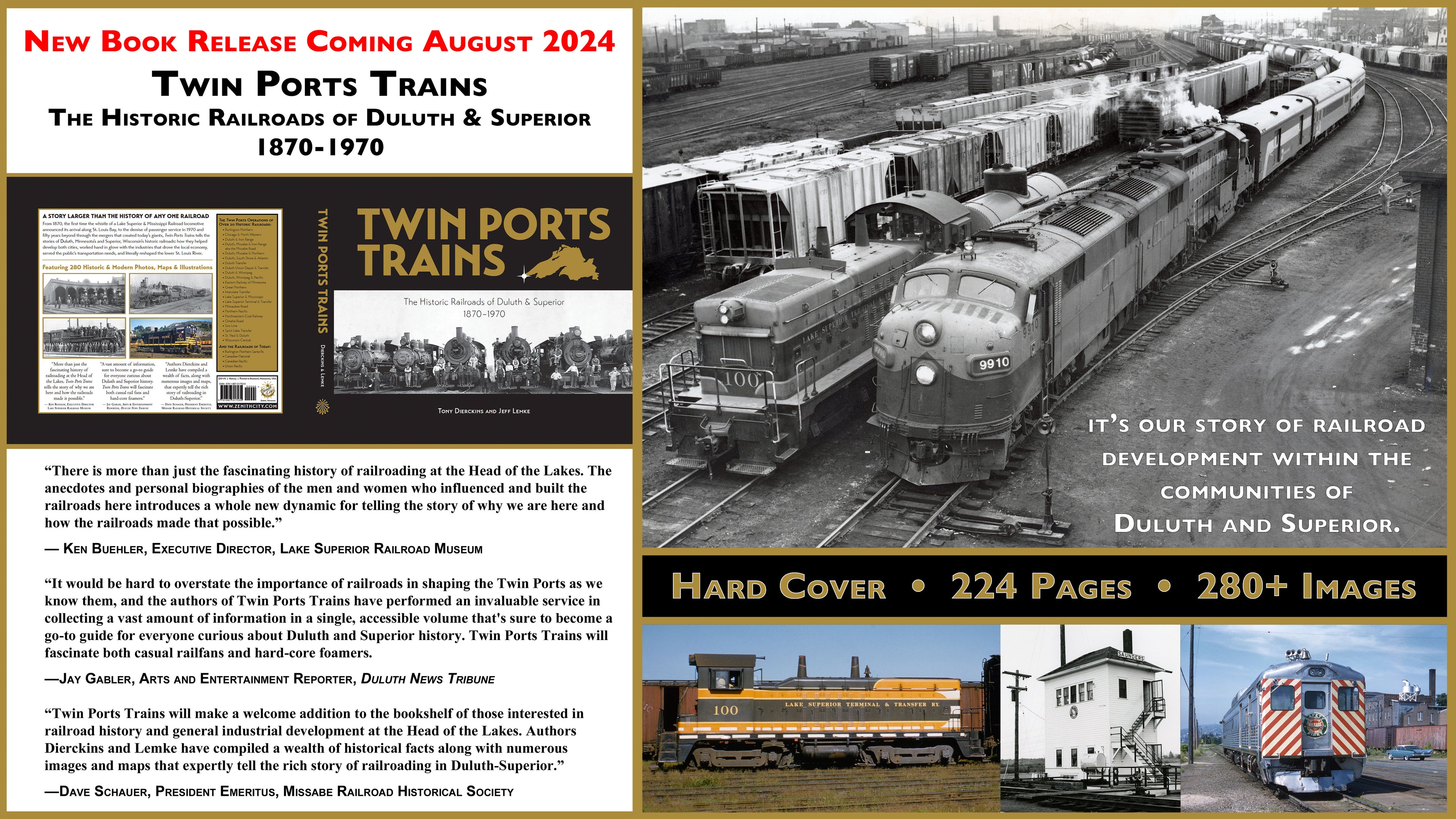

FYI — We wrote the book on railroads too!

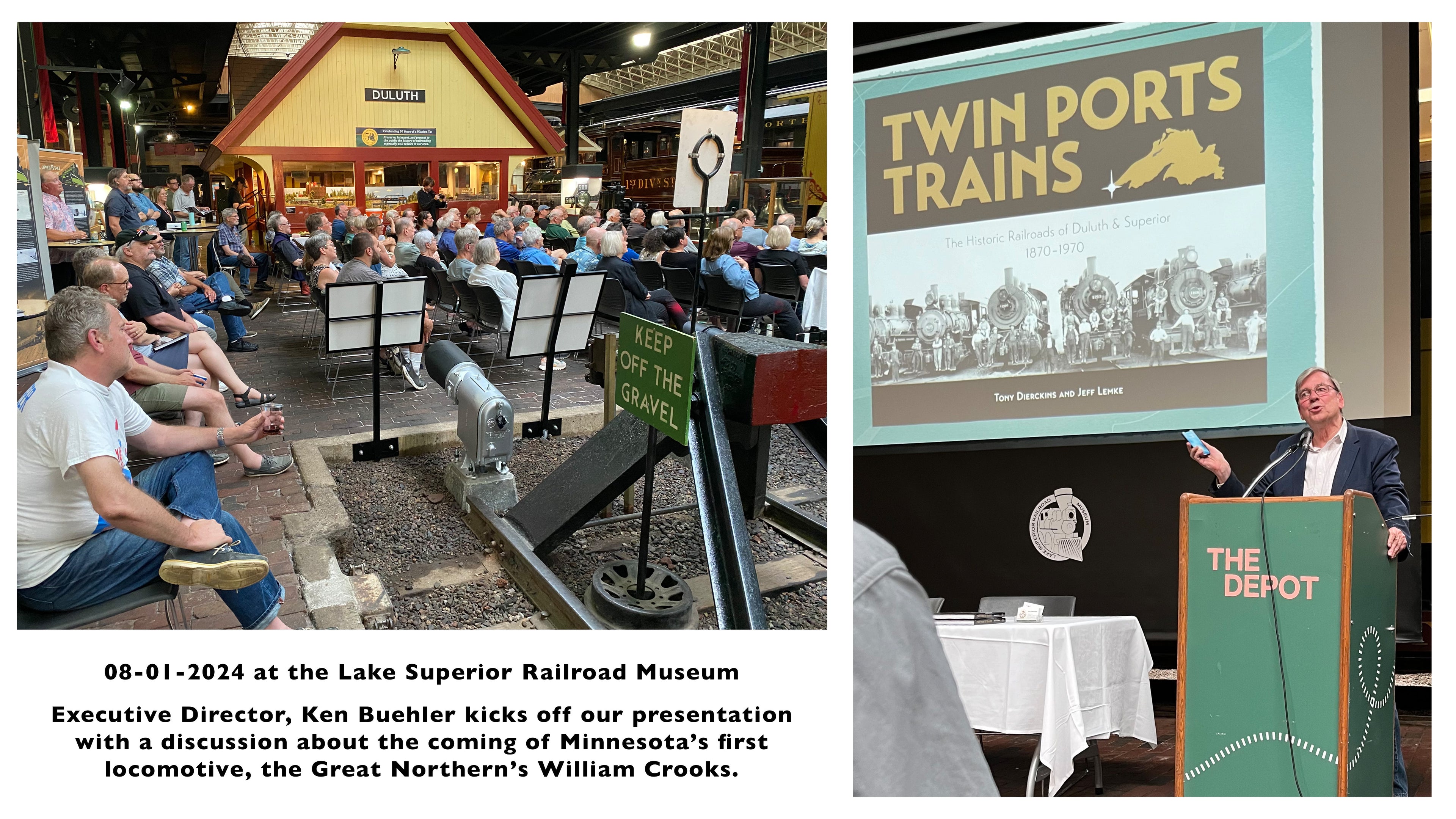

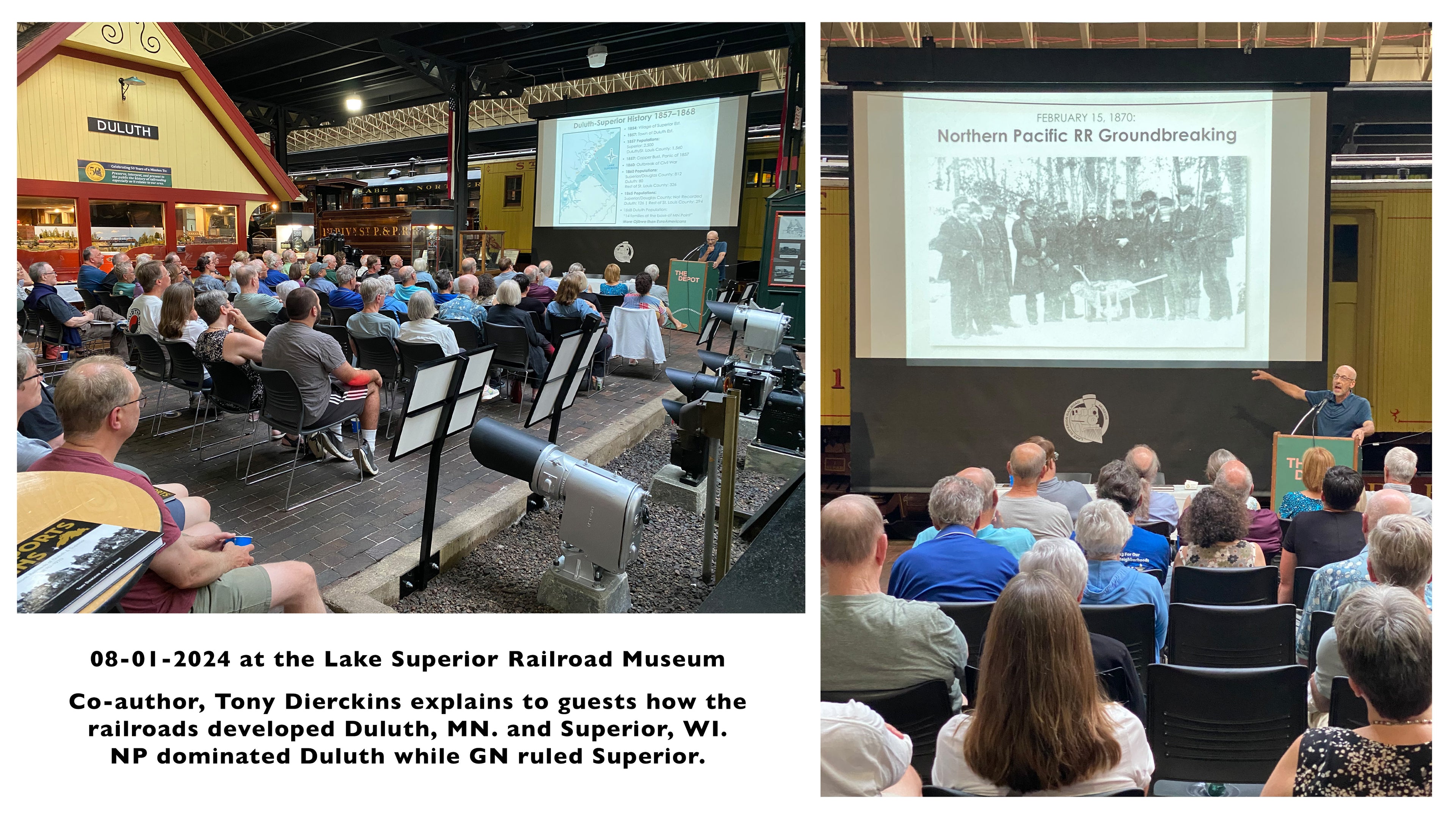

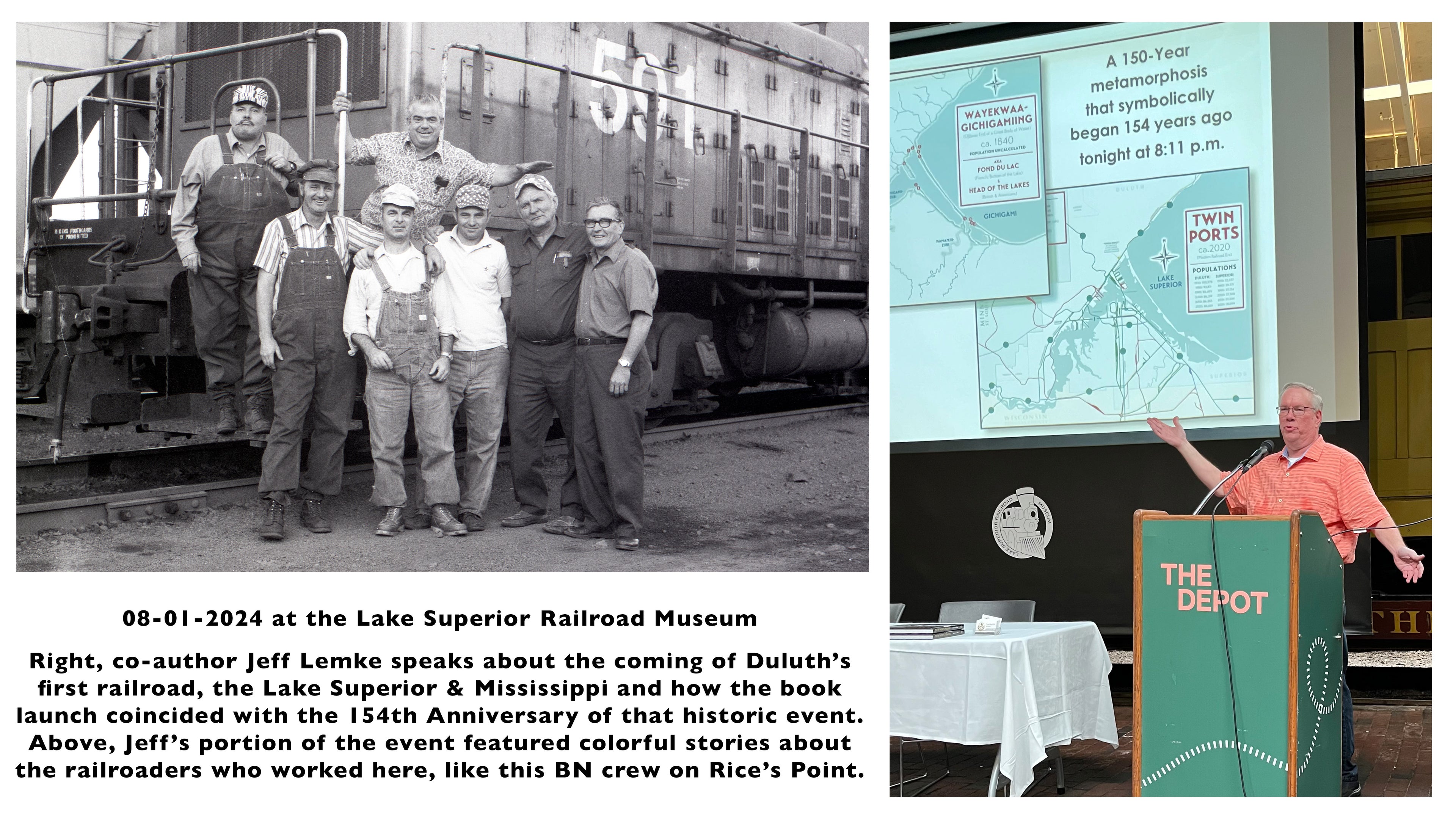

11 years in the making, this rich history of railroading explains how each railroad contributed to the creation of Duluth, Minnesota and Superior, Wisconsin—also known as The Twin Ports. Our project includes the LS&M, StP&D, NPRR, NPRY, CStPM&O, C&NW, Duluth & Winnipeg, Eastern Railway of Minnesota, Great Northern, D&IR, DM&N, DM&IR, DSS&A, WC, Soo Line, DW&P, Milwaukee Road, DUD&T, LST&T, and even the Northwestern Coal Railway. The images below show our official book launch at the Lake Superior Railroad Museum located in the lower level of historic Duluth Union Depot. Only a limited number of author-signed books remain available for sale in our eBay Store.

If you enjoy the railroads of Duluth-Superior and Minnesota's Mesabi Iron Range as much as we do, then you're going to LOVE our new book. If you already have your signed edition, and want to learn even more about this fascinating railroad terminal, then be sure to CLICK HERE to visit our Flickr site to see hundreds more images with detailed stories that describe each railroad scene—and the industries they served.